The EDEM Powders Database

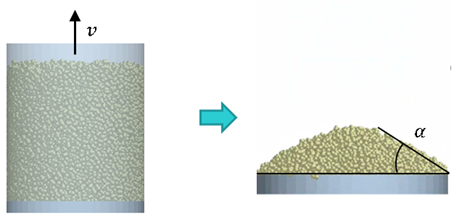

The following figure describes the angle of repose test using the lifting cylinder method. The physical measurement of the static angle of repose can be conducted according to ASTM 6393 or similar test methods.

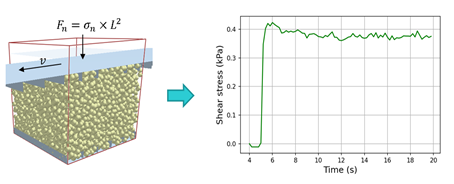

The following figure describes direct shear test under constant normal stress. The measurement of the steady state shear stress corresponds to the pre-shear stage of a shear cell test performed according to ASTM 6128 or ASTM D6773. Steady-state shear stress results are available for 1kPa and 5kPa normal stresses.

In the interest of computational efficiency, a meso-scopic modelling approach is adopted for the EDEM powder models.

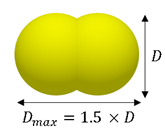

The two-sphere particle shape shown in Figure 3 and the normal relative particle size distribution described in the table are adopted to capture shear dilation effects and avoid non-physical packing states (Härtl, J., & Ooi, J. Y., 2011). The standard particle diameter in the database D_max is 1.5 mm, but different values can be used in certain cases.

The interaction forces at the meso-contact scale are described with the Edinburgh Elastic-Plastic-Adhesive (EEPA) and Type C rolling friction models.

The following table contains information about the model parameter space.

| Particle size distribution | |||

| Type | Dmin/D50 | Dmax/D50 | σ/D50 |

| Normal | 0.85 | 1.15 | 0.15 |

| Fixed parameter space | |

| Particle Poisson’s ratio v | 0.25 |

| Particle Shear Modulus G (Pa) | 1e+7 |

| Particle solid density ρs (kg/m3) | 1000 |

| Particle coefficient of restitution e | 0.1 |

| Particle – geometry coefficient of static friction μg | 0.5 |

| Particle – geometry coefficient of rolling friction μrg | 0.1 |

| EEPA tangential stiffness multiplier ktan | 0.667 |

| EEPA loading exponent n | 1 |

| EEPA tensile exponent kadh | 3 |

| Variable Parameter space |

| Particle – particle coefficient of static friction μs |

| Particle – particle coefficient of rolling friction μr |

| EEPA constant pull-off force f0 |

| EEPA surface energy γ (J/m2) |

| EEPA contact plasticity ratio λ |

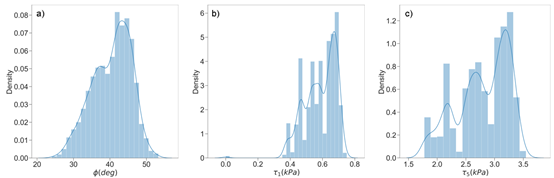

The following figure shows the 1500 material models in the database and the probability density distributions for the following responses:

- the static angle of repose

- the steady state shear stress at 1 kPa normal stress

- the steady state shear stress at 5 kPa normal stress

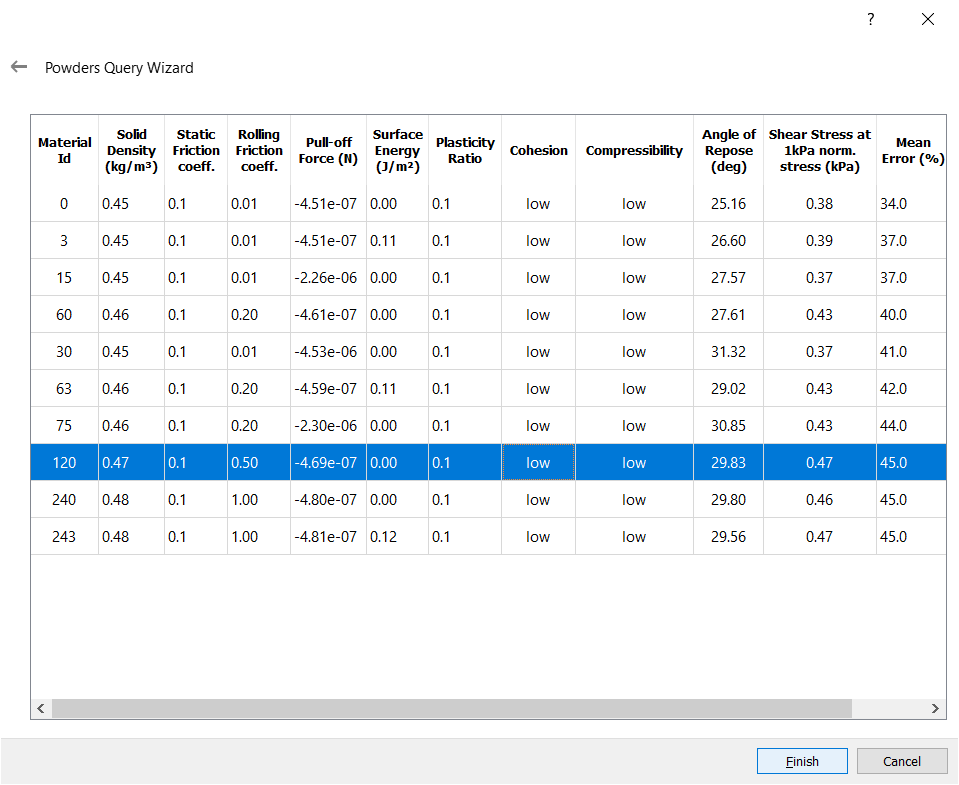

The database can be searched using multiple responses at the same time, and the results are sorted based on the total relative error between the requested response values and the database results.

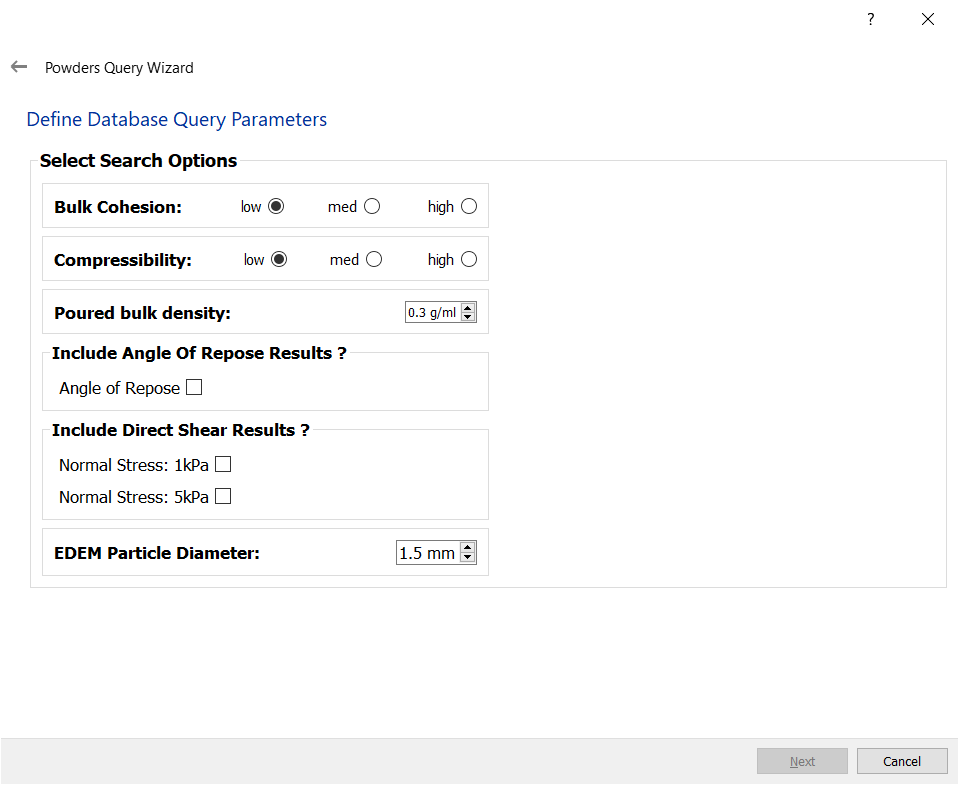

The required inputs for the search are:

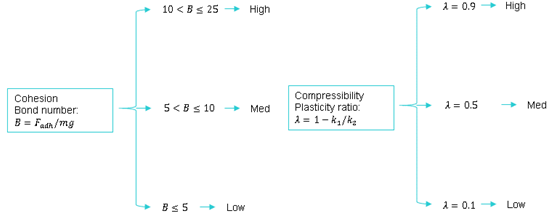

- The bulk cohesion and compressibility, which are qualitatively categorized using the bond number and the EEPA contact plasticity ratio respectively.

- The bulk density, which his captured via particle solid density and Bond number scaling of the baseline values in the dataset, and has variable ranges for the different bulk cohesion levels.

- The mean particle diameter, which is available as an input if the search includes only steady state shear responses. The scaling rules proposed by Thakur et. al are applied to compute the relevant parameter values in this case.

Using the EDEM Powders Database

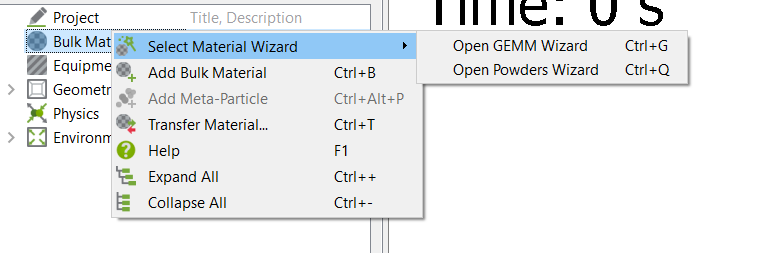

Navigate to Bulk Materials > Select Materials Wizard > Open Powders Wizard to access the Powders Database.

Follow the steps in the wizard and specify the input parameters for the Soils database.

In the list of materials, select an appropriate material to populate the material and model parameters in the EDEM GUI.

(c) 2023 Altair Engineering Inc. All Rights Reserved.