The GEMM Database

The GEMM database addresses one of the most difficult aspects of DEM simulation - obtaining appropriate material inputs for accurate representation of bulk materials. Thousands of Multi-Sphere material models representing a wide range of materials, such as rocks, soils, and ores, are stored in the GEMM database. It is ideal for mining, construction, and agriculture engineers who design heavy equipment that handles such materials.

You can access the GEMM database's extensive material information to view example materials and download input decks for use in their EDEM simulation by answering three questions about the Bulk Material and one question about the Equipment Material.

Using the GEMM Wizard

In the Creator Tree, right-click in either the Bulk Material or Equipment Material section and select the Open GEMM Wizard.

The first page is a description of the database, read, select Search by Material Properties and click Next to answer the 3 questions on the particle Bulk Material behavior.

Alternatively, to retrieve a bulk material you have already searched for you can select Search by Material Name and specify the ID number of that GEMM material.

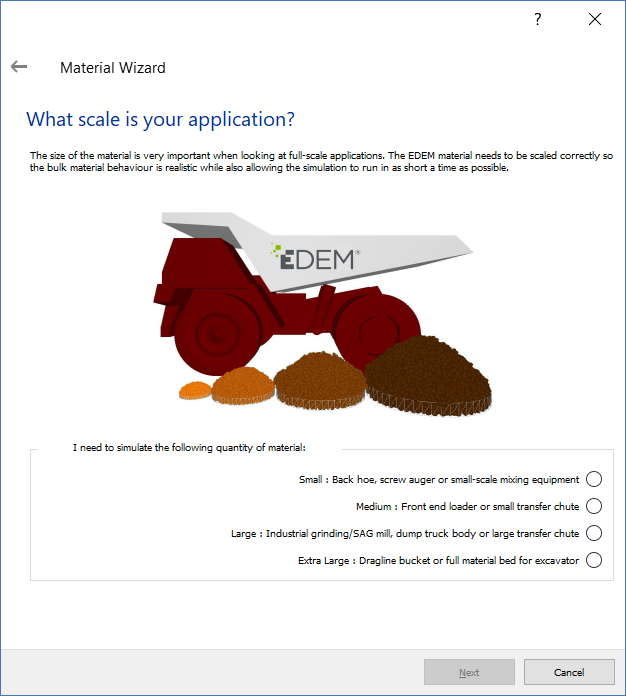

- What scale is your application?

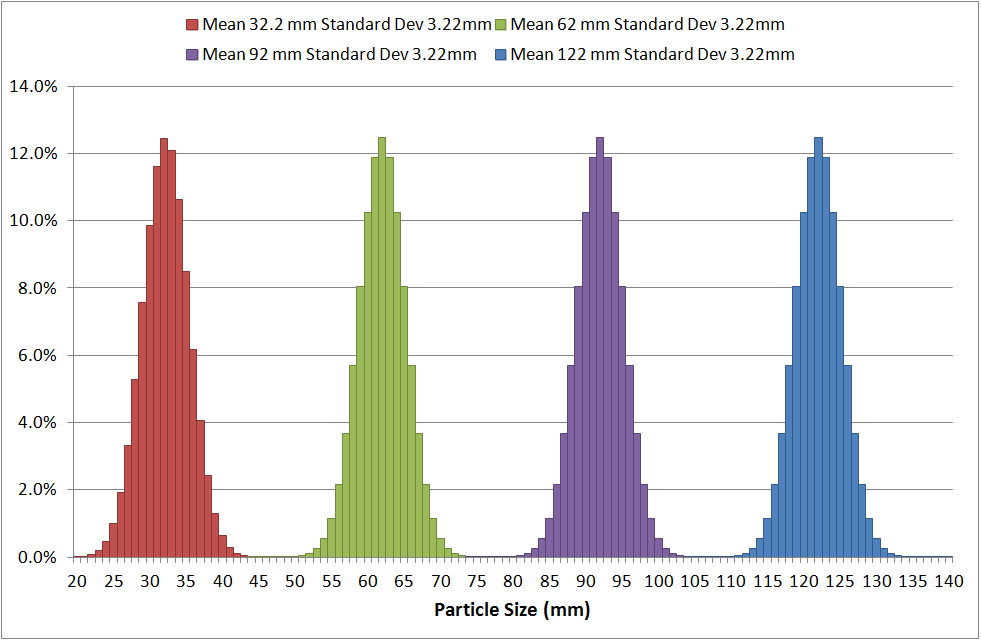

The GEMM Database contains several different sets of materials which are designed to cover a range of different material sizes. Each one has a size distribution based around a median value.

If you are not sure of the size distribution, start with the largest and test it on the application. It is faster to work with a test case where the particles are too large than it is to work with a case where they are too small because - with a large scale material - the particle count will be lower and therefore the simulation will progress quickly. If the particles are too small, it can take slow down the time taken to fill a volume instead of progressing with the simulation.

The actual size ranges used in the GEMM database are as follows:

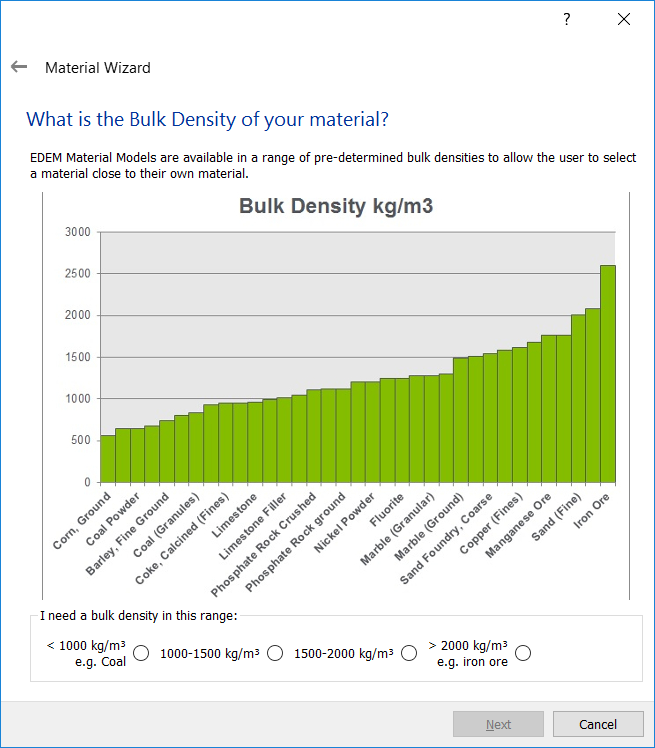

- What is the Bulk Density of your particle material?

Material Bulk Density is the ‘mass of the material (+ moisture content)’ / ‘volume of the material as a whole.

If the interface allows you to pick a material Bulk Density within a range.

If the real particle material Bulk Density lies close to the edge of one of the ranges, you can modify it after the generation of the material file.

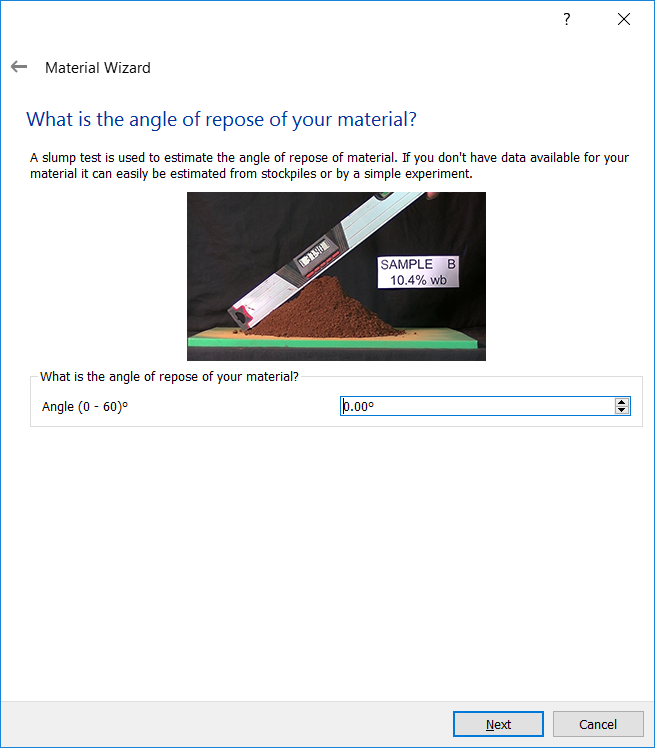

If a closer match to the bulk density is required, you can perform a small study with variations of the material solids density using the provided GEMM material as a starting point. - What is the angle of repose of your material?

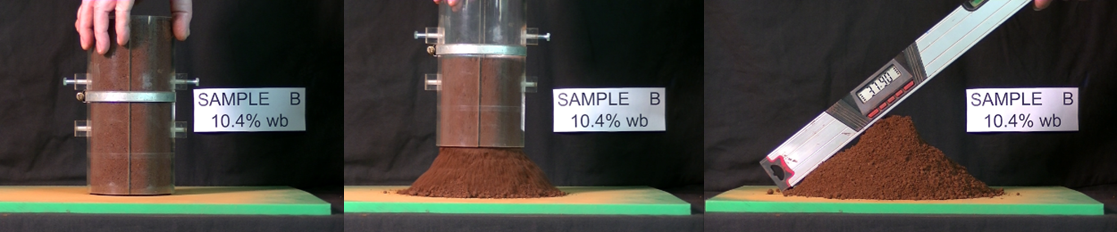

The angle of repose is a commonly available measure of material that is contained in standard test data. Even if such data is not available in existing material data reports, it is a quantity that can be measured in a relatively easy way without specialist equipment (for example, observing the angle of a stockpile). Finally, if there is no access to any testing reports or on-site data, then it is a quantity that is relatively easy to estimate based on engineering experience.

.

.

It is difficult to measure an angle of repose to a high accuracy so it is usually treated as an approximation to the material behavior rather than defining it completely. For this reason the material model provided by the GEMM Database should be used as a guide or starting point, and you must be aware that differences in behavior might still occur.

The following example demonstrates the angle of repose test:

The maximum value for Angle of Repose in the GEMM database is 60 degrees, and any materials with angles higher than this should be calibrated separately, The lowest angles can be found between 20 and 30 degrees.

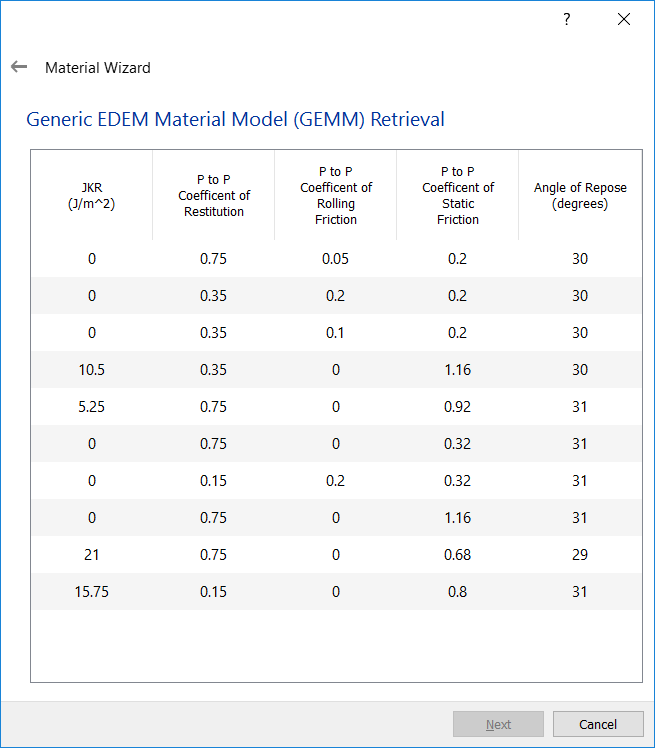

Once you have answered these three questions, a list of ten materials is provided which are the 10 closest matches based on the answers that have been given.

You can choose from one of these materials, the top material is the closest match to the input angle of repose. However, you can also select other materials from the list.

P to P refers to the Particle to Particle values of Restitution, Static Friction and Rolling Friction.

The JKR value is the cohesive energy value for this material. A ‘sticky’ material will tend to have a higher JKR value than a non-sticky material even if both materials have the same angle of repose.

High JKR cohesion values are best paired with higher coefficients of restitution to avoid overly damped simulations.

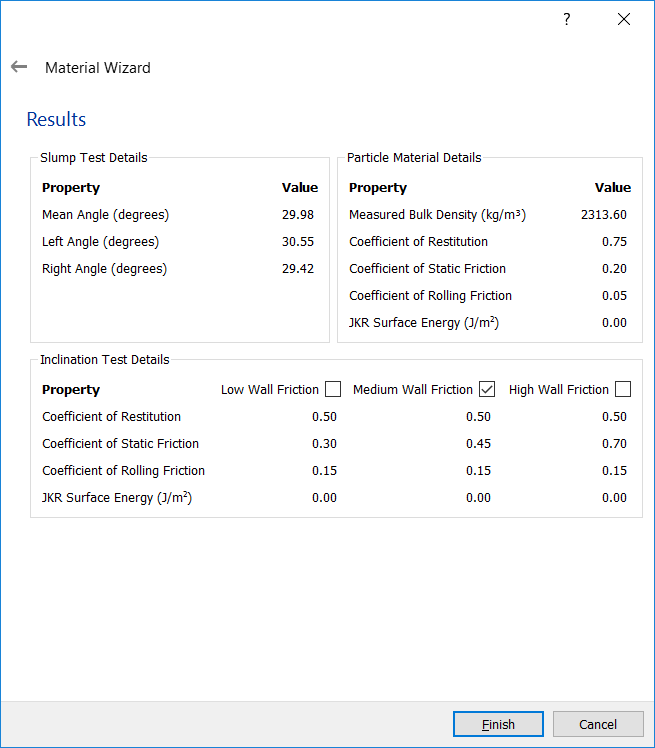

Once you have selected a material, the material details including the measured material Bulk Density value for this specific material are provided. - Select any of the Equipment Interactions for this material:

- Low Friction

- Medium Friction

- High Friction

- Select Finish to add the Bulk Material to the simulation. This material is added to the following areas:

- Bulk Material

- Properties

- Shape

- Size Distribution

- Interactions (Bulk Material - Bulk Material and Bulk Material - Equipment Material)

Medium friction is designed around a material such as Steel. The material friction is based around an Inclination Test. A sample of the Bulk Material is placed on a flat plate, the plate is then inclined until the material begins to slide. A material with a low Bulk Material angle of repose will slide at a lower inclination angle than a material with a high Bulk Material angle of repose. As such, the Bulk Material is characterized as Low Angle (Repose Angle less than 35 degrees), Medium Angle (Repose Angle Greater than 35 degrees but Less than 45 degrees) and High Angle (Repose Angle Greater than 45 degrees).

The Geometry Interactions are then provided based on the following table:

| Material Type | Geometry Type | Static Friction (p-g) | Rolling Friction (p-g) | JKR Cohesion (p-g) | Inclination Test Results (average results) |

| Low Angle | Low Friction | 0.3 | 0.15 | 0 | 21 |

| Low Angle | Medium Friction | 0.45 | 0.15 | 0 | 27 |

| Low Angle | High Friction | 0.7 | 0.15 | 0 | 34 |

| Medium Angle | Low Friction | 0.45 | 0.15 | 0 | 28 |

| Medium Angle | Medium Friction | 0.7 | 0.15 | 0 | 35 |

| Medium Angle | High Friction | 1 | 0.15 | 0 | 39 |

| High Angle | Low Friction | 0.7 | 0.15 | 0 | 37 |

| High Angle | Medium Friction | 1 | 0.15 | Low | 46 |

| High Angle | High Friction | 1.7 | 0.15 | High | 49 |

(c) 2023 Altair Engineering Inc. All Rights Reserved.