Advanced (RADIOSS Incremental) |

|

|

|

|

|

Advanced (RADIOSS Incremental) |

|

|

|

|

The Advanced panel provides users a means of running analyses using several options.

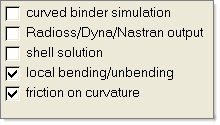

The options available are:

Options |

Description |

curved binder simulation |

Allows you to choose binder and part components for an analysis that unfolds the blank on a curved binder. The curved binder is assumed to be close to developable and its boundary should be wide enough to accommodate the blank after the unfolding. |

RADIOSS/Dyna/Nastran output |

Allows you to write out a results file which can be directly used to initialize a structural analysis model. The names for the output files are: filename_thk.nas and filename_dyna.k corresponding to Nastran and Dyna solvers respectively. filename_thk.nas contains the mesh data along with the nodal thickness. filename_dyna.k contains the mesh and the nodal thickness, followed by the stress tensor and plastic strain at each integration point within an element. Please see the Transferring Forming Results to Crash Analysis tutorial for more details. When this option is enabled, you can select the number of integration points through the shell thickness for which the results will be output under the _rd.sta and _dyna.k files. Additionally, it is possible to request the same files to be written out without the mesh data. |

shell solution |

Activates the through-thickness integration algorithm inside the solver, which then computes the possible strain variation along the thickness direction of the sheet metal. This allows you to review not only the strain values on the mid-surface, but also on top and bottom surfaces of the sheet metal. |

local bending/ unbending |

Simulates the effects due to localized bending and unbending of the sheet metal as it moves over a curved surface. This option is automatically disabled when undercut is detected. Because bending simulation is not accurate when undercut exists, you should also manually check whether undercut exists before enabling this option. |

friction on curvature |

Simulates the frictional effects on straining due to the dragging of sheet metal over a curved surface. |

Before setting up a curved binder analysis, it is necessary to have a component defined for the part as well as the binder with appropriate material properties and thickness using the components panel. See the Components and Materials panels for more information.

|

|