In this tutorial, you will learn how to import a HyperMesh model containing the geometry of a hollow profile, set up an indirect extrusion model and finally export for a hollow profile. The steps to follow are:

| 1. | Import the HyperMesh file with hollow profile geometry. |

| 2. | Generate solver input files using the Extrusion Wizard |

The model files for this tutorial are located in the file mfs-1.zip in the subdirectory \hx\MetalExtrusion\HX_0155. See Accessing Model Files.

To work on this tutorial, it is recommended that you copy this folder to your local hard drive where you store your HyperXtrude data, for example, “C:\Users\HyperXtrude\” on a Windows machine. This will enable you to edit and modify these files without affecting the original data. In addition, it is best to keep the data on a local disk attached to the machine to improve the I/O performance of the software.

| 1. | From the Start menu select: All Programs > Altair > HyperXtrude to launch the HyperXtrude user interface. |

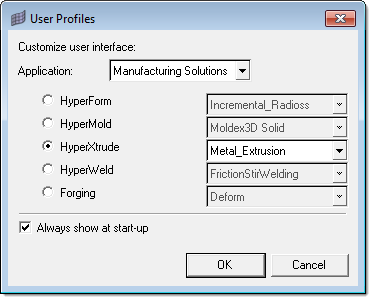

| 2. | The User Profiles dialog appears with Manufacturing Solutions as the default application. If it does not appear, you can access it from the menu bar by clicking Preferences > User Profiles. |

| 3. | Select HyperXtrude and Metal Extrusion. |

|

| 1. | Access the Import tab in one of the following ways: |

| • | From the File menu, click Import. |

| • | Click the icon  . . |

| 2. | Click the Import HM model icon  to set the Import File Type to HM model. to set the Import File Type to HM model. |

| 3. | Click the Select Files icon  and select the file HX_0155.hm and select the file HX_0155.hm |

| 5. | Click Close to close the Import tab. |

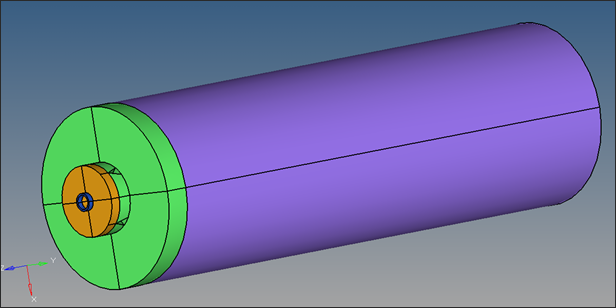

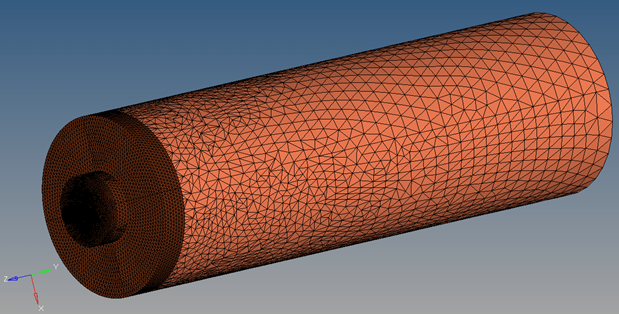

The model contains the hollow profile model. It has four components: Billet, Porthole, WeldChamber and Bearing.

|

| 1. | On the Utility Menu, click Extrusion Wizard. Depending on how you loaded the model, the Project Browser may prompt you for additional action (see HX-0004 for details). |

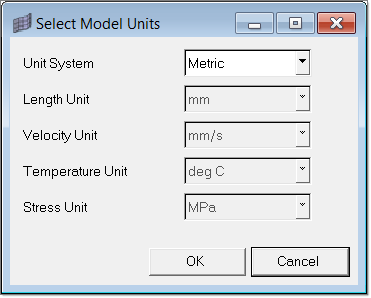

| 2. | In the Extrusion Wizard, click Set Model Units. |

Note: Measure dimensions of the model by pressing F4 button on the key board to get an idea about the units of the model.

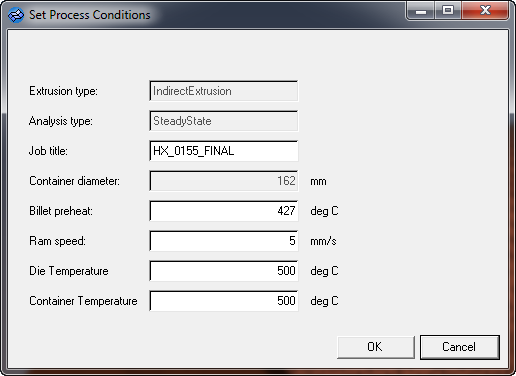

The length unit of the current model is mm (Billet diameter is about 162).

| 3. | Set the Unit System field set to Metric and set the options as shown in the figure below. Click OK. |

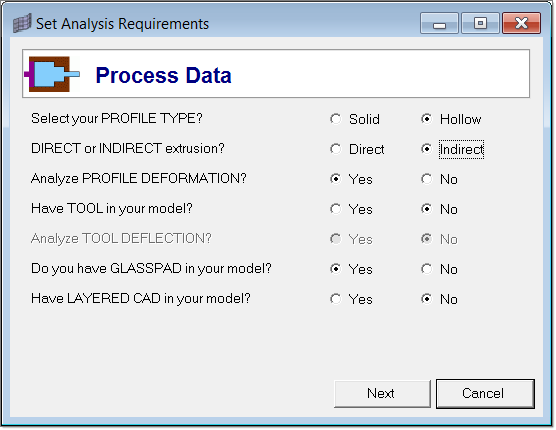

| 4. | Click Set Analysis Requirements. |

| 5. | Set the Process Data as shown below. Select Hollow for Select your PROFILE TYPE? and Indirect for DIRECT or INDIRECT extrusion? Accept the default data for all other options and click Next. |

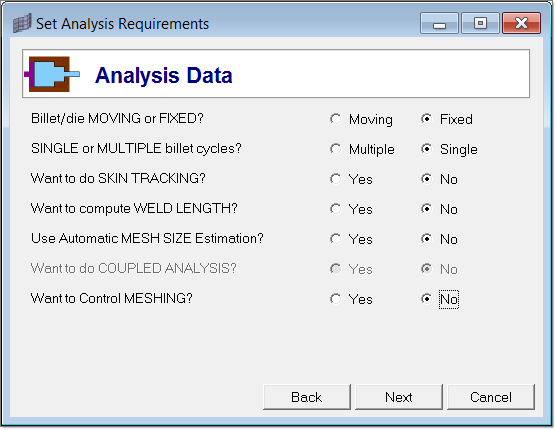

| 7. | In the Analysis Data page, set the options as shown below. |

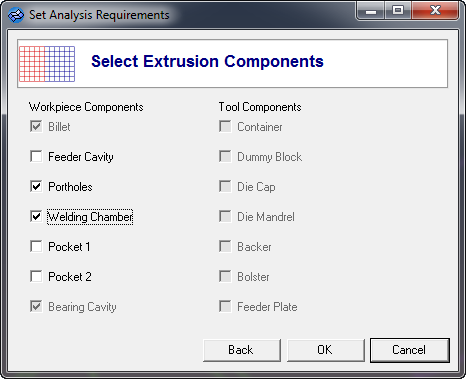

| 8. | Click Next again to select the extrusion components. In the Select Extrusion Components page, notice that the Extrusion Wizard already selected the components Billet and Bearing Cavity. Select Portholes and Welding Chamber and click OK to save the data and close window. |

You will skip the Select Press Data option as the model does not have that information.

|

| 1. | Click Select Material Data. |

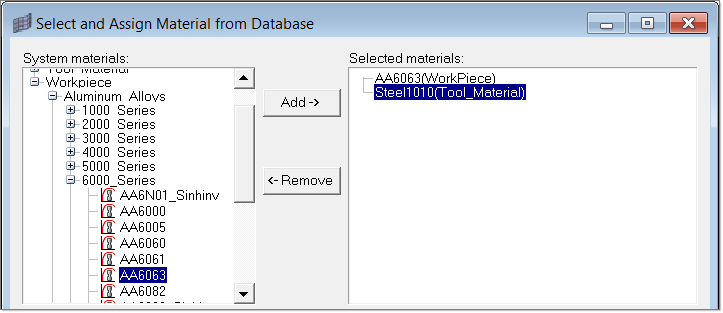

| 2. | Expand Workpiece, then expand Aluminum_Alloys and expand 6000_Series. |

| 3. | Select AA6063 and click Add-> to add the material under Selected Materials. |

You do not need to assign a material in the Extrusion Wizard. The selected material will be assigned to the workpiece automatically.

| 4. | Click Close to close the Select and Assign Material from Database window. |

|

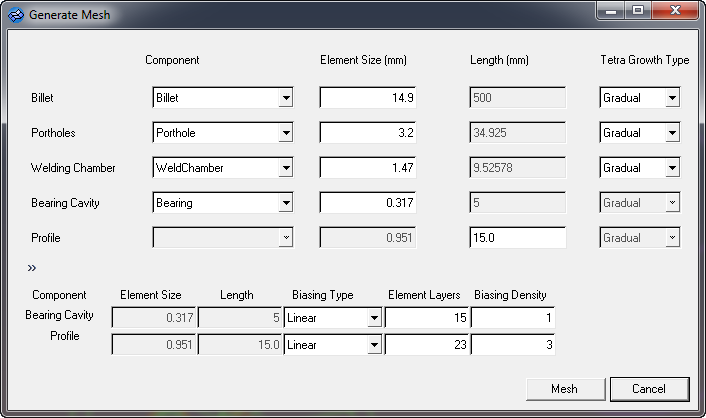

| 1. | Click the Generate Workpiece Mesh option. Notice that the Extrusion Wizard already picked the components for Billet, Porthole, Welding Chamber and Bearing Cavity. |

Note: Always rename the components by proper names so that the Extrusion Wizard identifies the components by default.

| 2. | Input the size of the elements as shown below. |

| 4. | After the mesh is created, click OK and close the window. |

In Model Browser, notice that four new components, Billet3D, Porthole_WC3D, Bearing3D, and Profile3D are created.

| 5. | Click on Model Summary and verify the mesh quality. If the mesh is acceptable, click OK to save and close the window. If you want remesh with different element sizes, click the Remesh button. |

|

| 1. | Click Generate Workpiece BCs and accept the default process conditions. |

| 2. | Click OK. This creates BC faces and associated load cards for all the 3D collectors. |

| 3. | Click on the Model Browser tab and notice that related Boundary Conditions components are created. |

|

| 1. | Click File > Save As…. and save the file as HX_0151_FINAL.hm. |

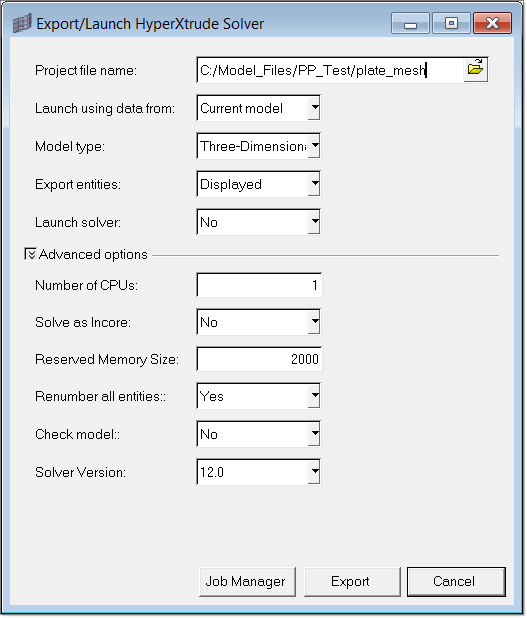

| 2. | In the Extrusion Wizard, click Save and Export the Model. |

| 3. | Browse to choose the correct location for Project file name: |

| • | Model type:= Three-Dimensional |

| • | Renumber all entities: = Yes |

| 4. | Click Export to generate HX_0155_final.grf and HX_0155_final.hx files. |

The .hx and .grf files can be passed to the HyperXtrude solver for solving analysis.

|

| 1. | Run HyperXtrude interactively or in batch mode. |

| 2. | Once the analysis is completed, post-process the results. |

|

Return to Metal Extrusion Tutorials