AcuTherm

Translates the AcuSolve solution to an input file for TAITherm.

Syntax

acuTherm [options]

Type

AcuSolve Post-Processing Program

Description

In the following, the full name of each option is followed by its abbreviated name and its type. See the description below for more details.

- help or h (boolean)

- If set, the program prints a usage message and exits. The usage message includes all available options, their current values and the source of their current values.

- problem or pb (string)

- The name of the problem is specified via this option. This name is used to build internal file names and to generate output files.

- working_directory or dir (string)

- All internal files are stored in this directory. This directory does not need to be on the same file system as the user-supplied input files.

- run_id or run (integer)

- The run number in which the translation is requested. If run_id is set to 0, the last run in the working directory is assumed; see the description below for more details.

- translate_to or to (enumerated)

- Translate the output to this format:

- taitherm

- Translate into a Patran file for TAITherm

- jmag

- Translate into a CSV format for JMAG

- abaqus

- Translate into a CSV format for Abaqus or general

- time_steps or ts (string)

- Comma-separated list of time steps to be translated. The comma-separated fields have the general range format beg:end:inc, where :end:inc and :inc are optional. beg specifies the first time step in the range. It may be either a given time step, as specified by a number, or the letter L (or l) requesting the last time step, or the letter A (or a) requesting all available time steps in the range.

- ignore_missing_steps or imts (boolean)

- If set, missing requested time steps are ignored. Otherwise, if the requested time step does not exist, the command issues an error message and exits.

- surface_output_sets or osfs (string)

- Comma-separated list of surface_output sets. These are the user-given names specified as the user given name of the SURFACE_OUTPUT commands in the input file. If surface_output_sets is set to _auto, all output sets are used.

- min_film_coefficient or mfc (real)

- Minimum acceptable film coefficient (default, 0). This value provides a lower bound on the surface_film_coefficient. Any values in the AcuSolve solution database that fall below this value are clipped. This option can be used to eliminate high reference temperatures that result from low film coefficients in regions of stagnant flow.

- num_temperature_filter_passes or ntfp (real)

- Number of passes for smoothing the temperature field.

- num_reference_temperature_filter_passes or nrfp (real)

- Number of passes for smoothing the reference temperature.

- num_film_filter_passes or nffp (real)

- Number of passes for smoothing the film coefficient.

- num_heat_filter_passes or nhfp (real)

- Number of passes for smoothing the heat flux field.

- film_calculation_type or fct (enumerated)

- Film coefficient calculation method.

- turb_wall

- Utilize the "Thermal Law of the Wall" to determine the surface film coefficient. This option requires that NODAL_OUTPUT and surface nodal output be available for all time steps of interest at each surface of interest.

- direct

- Compute the surface film coefficient by evaluating the nodal temperature at the surface as well as at some point at a specified distance away from the surface. This option utilizes thermal_layer_edge_y_plus to determine where in the domain to evaluate the reference temperature. This option requires that NODAL_OUTPUT, DERIVED_QUANTITY_OUTPUT and surface nodal output be available for all time steps of interest at each surface of interest.

- user_ref_temp

- Compute the surface film coefficient by using a user specified constant reference temperature. The reference temperature is provided by user_reference_temperature. This option requires that NODAL_OUTPUT and surface nodal output be available for all time steps of interest at each surface of interest.

- thermal_layer_edge_y_plus or tlyp (real)

- Distance away from the wall (in non-dimensional coordinates) where the solution is sampled to determine the local reference temperature. Used with film_calculation_type=direct.

- user_reference_temperature or urt (real)

- Constant reference temperature to use for evaluation of the film coefficient. Used with film_calculation_type=user_ref_temp.

- limit_reference_temperature or lrt (boolean)

- Flag specifying whether the reference temperature should be limited to the min and max values present in the nodal solution. Used with film_calculation_type = turb_wall.

- verbose or v (integer)

- Set the verbose level for printing information to the screen. Each higher verbose level prints more information. If verbose is set to zero (or less), only warning and error messages are printed. If verbose is set to one, basic processing information is printed in addition to warning and error messages. This level is recommended. Verbose levels greater than one provide additional information useful only for debugging.

AcuTherm translates the solution of a problem run by AcuSolve into either a Patran Neutral file suitable for running TAITherm, or a comma separated value (CSV) file suitable for use with JMAG, Abaqus or for other thermal associated applications.

acuTherm -pb underhood -osfs surface 1, surface 2 -to taithermproblem = underhood

surface_output_sets = surface 1, surface 2

to = taithermacuTherm- Card 25: Title Card

- Card 26: Summary Data

- Card 01: Nodal Data

- Card 02: Element Data

- Card 17: Convection Coefficients

- Card 18: Element Flow Data

The Nodal Data cards include only the nodes on the surfaces. The Element Data cards include all the output surfaces. The Convection Coefficients and Element Flow Data cards have the format defined by TAITherm. AcuTherm requires nodal output as well as surface nodal output for all surfaces involved. The former may be requested through the NODAL_OUTPUT command in the input file, while the latter is specified through the parameters nodal_output_frequency or nodal_output_time_interval of the SURFACE_OUTPUT command. For the case of film_calculation_type=direct, AcuTherm also requires that DERIVED_QUANTITY_OUTPUT be present. The options run_id and time_step specify the output run and time step for extracting the data. Either or both options may be set to 0, indicating the use of the latest data.

AcuSolve Thermal Wall Function - function of local surface y+ and local Prandtl number

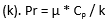

The local Prandtl Number (Pr) is computed as a function of local material viscosity (µ), specific

heat ( ) and conductivity

) and conductivity  .

.

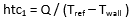

HTC Method 1 (AcuTherm method = user_ref_temp)

Q = local surface heat flux (in AcuSolve, if the solid surface is losing heat, then the sign of Q is positive for the solid surface and it will be negative for the fluid surface at the same location.)

= local wall temperature

= local wall temperature

= user-specified reference temperature (must be smaller than min[

= user-specified reference temperature (must be smaller than min[ ])

])

Use htc1 when comparing CFD with the experimental htc value computed using the same expression above. This is recommended when there is a well-defined reference freestream/bulk temperature.

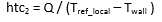

HTC Method 2 (AcuTherm method = direct)

Q = local surface heat flux (in AcuSolve, if the solid surface is losing heat, then the sign of Q is positive for the solid surface and it will be negative for the fluid surface at the same location.)

= local wall temperature

= local wall temperature

= local ref. temperature computed by AcuTherm at user-specified thermal layer edge yplus

= local ref. temperature computed by AcuTherm at user-specified thermal layer edge yplus

thermal_layer_edge_yplus = default value is 1000.0

Use htc2 when there is a well-defined reference freestream temperature in the streamwise direction.

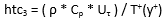

HTC Method 3 (AcuTherm method = turb_wall) - Same as surface_film_coefficient

ρ = local wall density

= local wall specific heat

= local wall specific heat

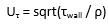

= local friction velocity

= local friction velocity

= local non-dimensional temperature at user-specified y+ (recommended y+ = 100)

= local non-dimensional temperature at user-specified y+ (recommended y+ = 100)

For example: Pr = 0.72 (air), T+(y+=100) = 13.7

You can set the y+ value to 100 using the thermal layer edge yplus option under the Turbulence Model Parameters command in the Advanced Solution Strategy panel.