HS-4000: Optimization Method Comparison: Arm Model Shape Optimization

Learn how to perform an Optimization and compare different methods for efficiency and effectiveness.

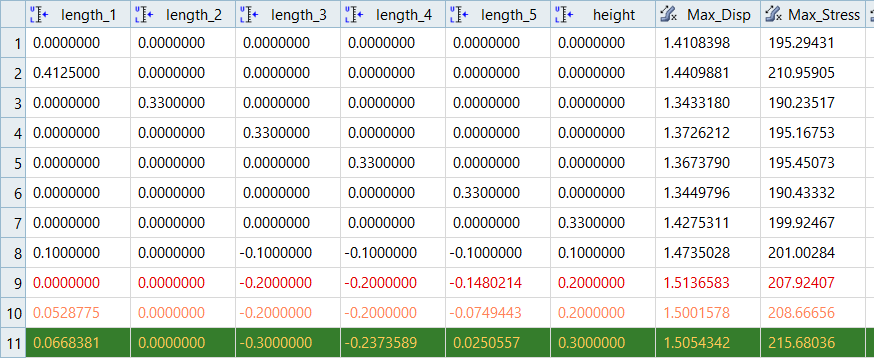

- Volume = 1.77E+06 mm3

- Max_Disp = 1.41 mm

- Max_Stress = 195.29 MPa

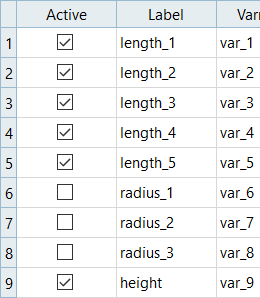

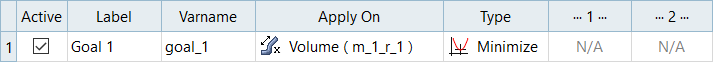

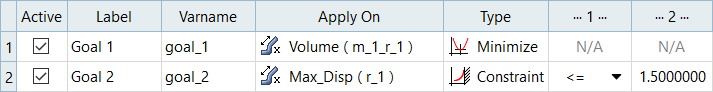

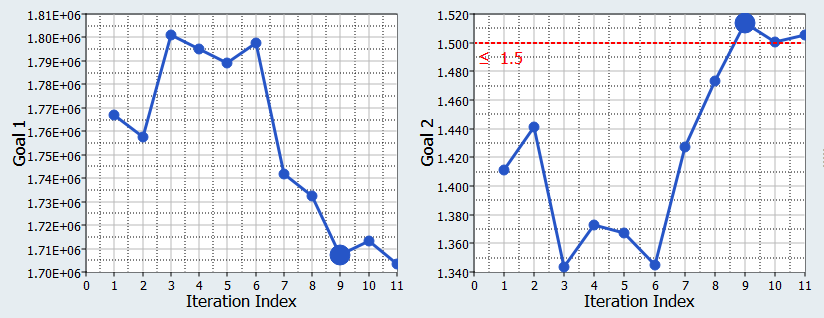

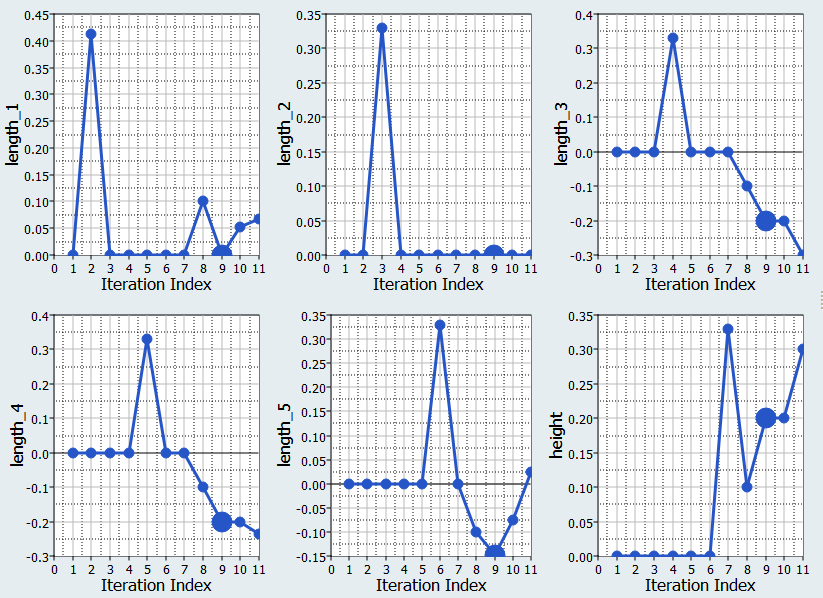

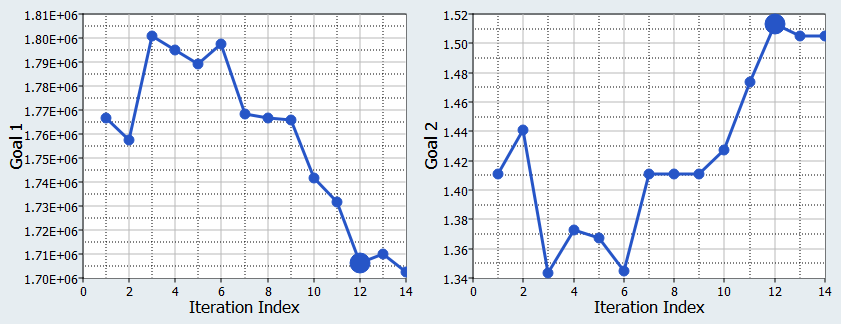

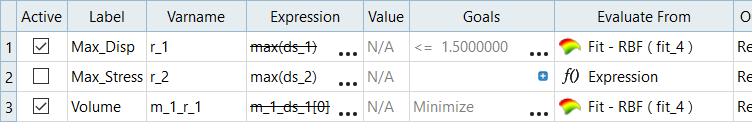

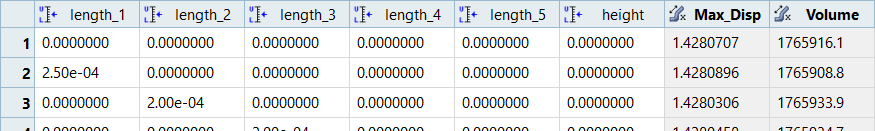

In this tutorial, the Optimization objective is to reduce Volume, while respecting a constraint on Max_Disp that should be less than 1.5 mm.

In HS-3000: Fit Method Comparison - Approximation on the Arm Model, you learned that it was difficult to accurately capture the Max_Stress function using a Fit approximation. In the DOE analysis, you learned that most of the tested design configurations for Max_Stress were below 300 MPa. For these reasons, you will not consider a constraint on the Max_Stress function. Max_Stress values can be collected throughout the Optimization when running the exact solver.

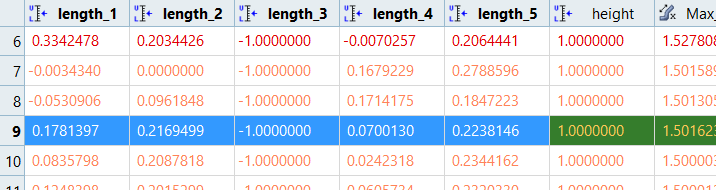

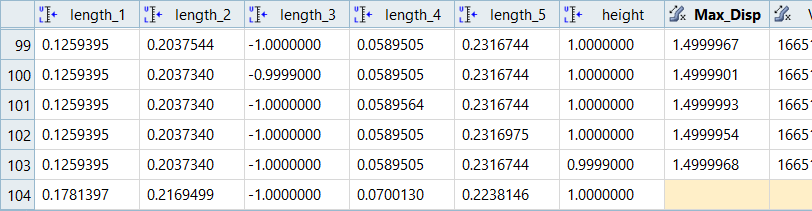

ARSM, Six Input Variables, Exact Solver

ARSM, Nine Input Variables, Exact Solver

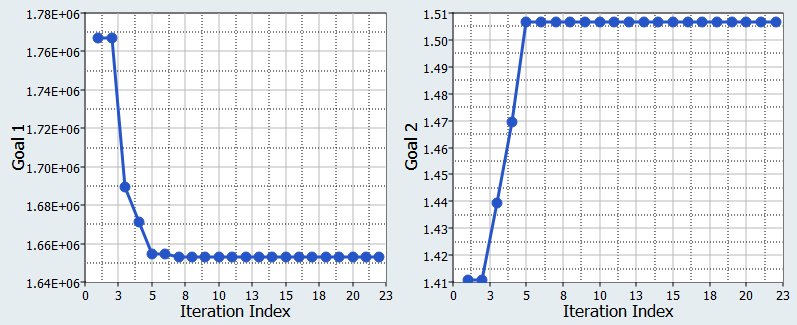

GRSM, Six Input Variables, Exact Solver

SQP, Six Input Variables, Exact Solver

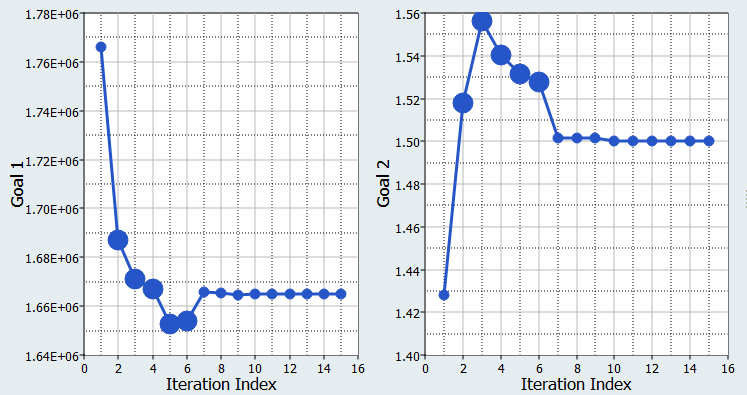

SQP, Six Input Variables, RBF_MELS

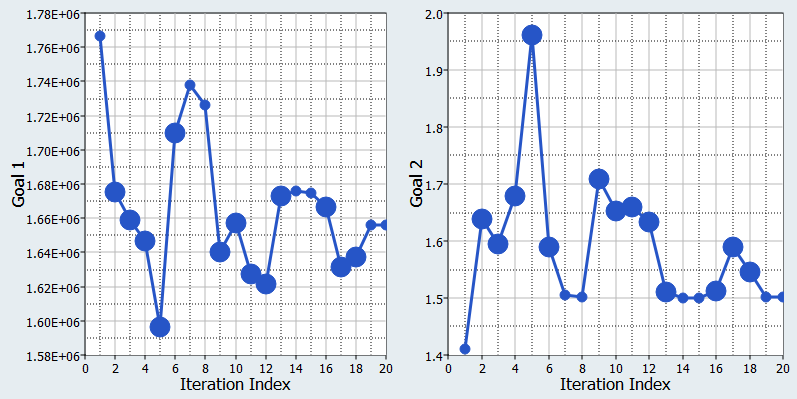

GA, Six Input Variables, RBF_MELS

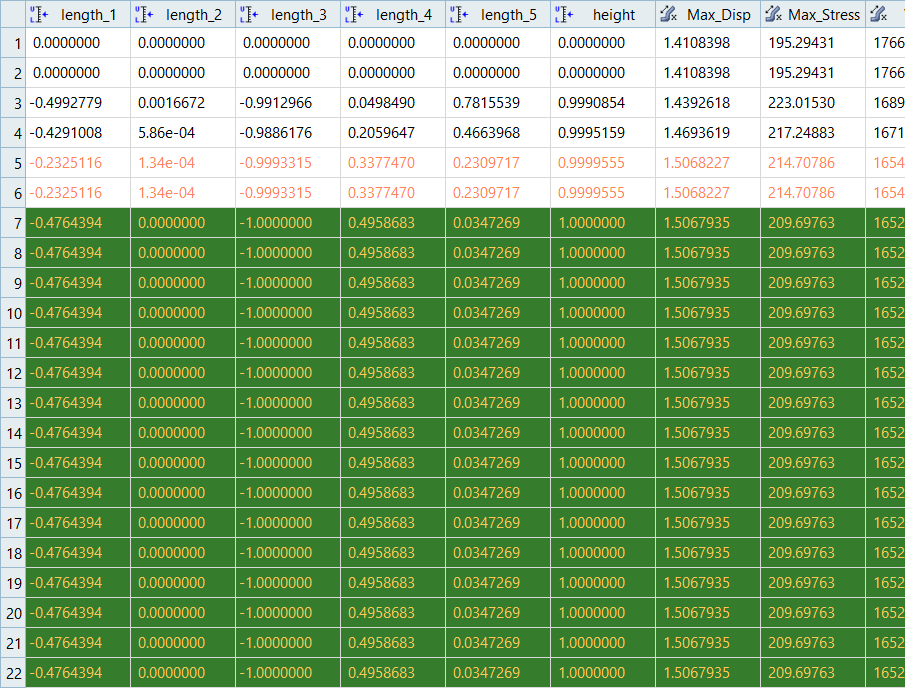

Optimization Methods Comparison

| Optimization Method | # of Evaluations | Volume Objective |

|---|---|---|

| ARSM, 9 IVs, Exact Solver | 14 | 1702450.0 |

| ARSM, 6 IVs, Exact Solver | 11 | 1703330.0 |

| GRSM, 6 IVs, Exact Solver | 50 (22nd is the optimum) | 1652830.0 |

| SQP, 6 IVs, Exact Solver | 179 | 1659730.0 |

| SQP, 6 IVs, Fit | - | 1666990.6 |

| GA, 6 IVs, Fit | - | 1665387.3 |

Reliability-Based Design Optimization Study

In this step, run a reliability based design optimization study.

This topic will be discussed in HS-5000: Stochastic Method Comparison: Stochastic Study of the Arm Model

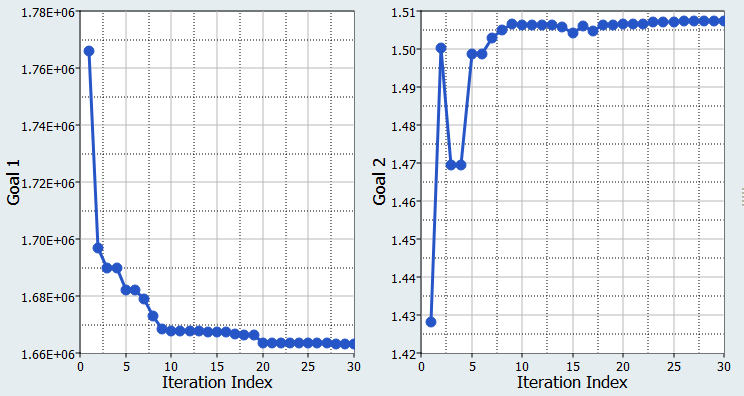

Multi-Objective Optimization Study

In this step, you will run a multi-objective optimization study.

This topic will be discussed in HS-4425: Multi-Objective Shape Optimization Study.