HS-4600: Motor Design Optimization for Ripple Torque Reduction

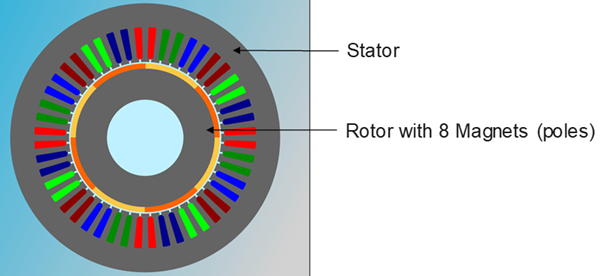

This tutorial is centered around a synchronous permanent magnet motor designed with Altair FluxMotor tool. The goal of this tutorial is to achieve an optimal magnet shape to minimize the ripple torque at a specific working point while maintaining the torque reached at this working point and without increasing the magnet mass.

Before you begin, copy the model files used in

this tutorial from <hst.zip>/HS-4600/ to your working

directory.

Perform the Study Setup

- Start HyperStudy.

-

Start a new study in the following ways:

- From the menu bar, click File > New.

- On the ribbon, click

.

.

- In the Add Study dialog, enter a study name, select a location for the study, and click OK.

- Go to the Define Models step.

-

Add a FluxMotor connection.

- In the Define Models tab, select Add Model.

- In the Add dialog, select FluxMotor and click OK.

The FluxMotor model is created and a FluxMotor solver script is automatically populated. -

Specify the path for the FluxMotor solver

script.

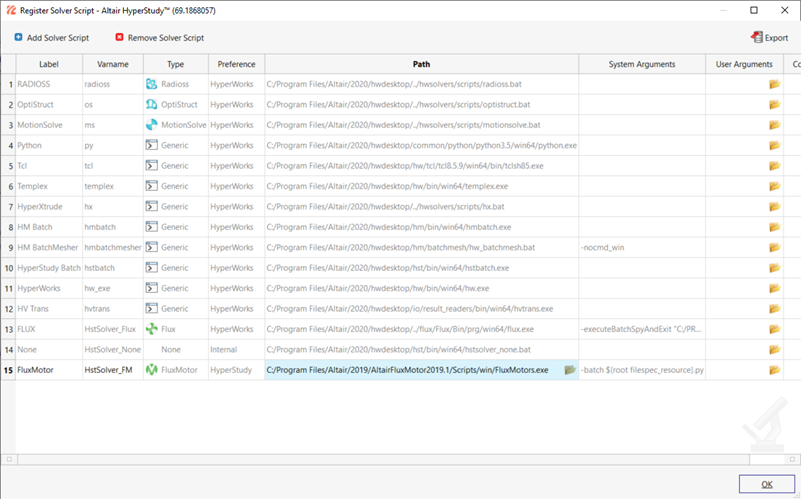

- From the Define Models step, click the Solver Execution Script cell and select Register new Solver from the drop-down menu.

-

In the Register Solver Script dialog, click

in the Path cell.

in the Path cell.

- Specify the path for the FluxMotor solver script as ..\AltairFluxMotor2020.1\Scripts\win\FluxMotors.exe.

- Click OK.

Figure 2. -

Establish resource file.

-

In the Resource column, click

.

.

- In the HyperStudy - Load model resource dialog, select HstConnector.fm2hst and click OK.

-

In the Resource column, click

- Click Import Variables.

-

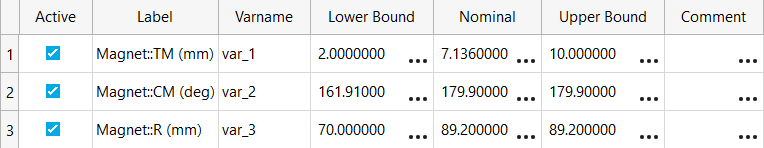

Go to the Define Input Variables step.

-

In the Bounds tab, edit the Lower Bound and Upper Bound as shown

below.

Label Lower Bound Upper Bound Magnet::TM (mm) 2 10 Magnet::CM (deg) 161.91 179.9 Magnet::R (mm) 70 89.2

Figure 3.

-

In the Bounds tab, edit the Lower Bound and Upper Bound as shown

below.

- Go to the Test Models step and click Run Definition.

- Go to the Define Output Responses step.

-

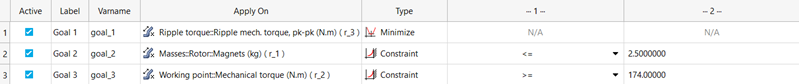

Go to the Objectives/Constraints - Goals tab and define

the following goals:

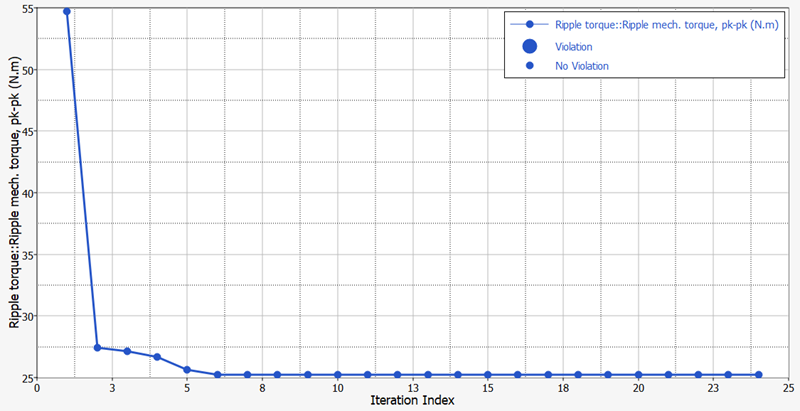

Apply On Type Column 1 Column 2 Ripple torque::Ripple mech. torque, pk-pk (N.m) (r_3) Minimize N/A N/A Masses::Rotor::Magnets (kg) (r_1) Constraint <= 2.5 Working point::Mechanical torque (N.m) (r_2) Constraint >= 174

Figure 4.

Perform Optimization

-

Add an Optimization.

- In the Explorer, right-click and select Add from the context menu.

- In the Add dialog, select Optimization and click OK.

Tip: When the Definition from field in the Add dialog is set to Setup, the variables and goals defined in the Setup will be automatically populated in the Optimization approach. As a result, you can skip the Definition step. - Go to the Specifications step.

- Select Global Response Search Method (GRSM) and click Apply.

-

Go to the Evaluate step and click Evaluate

Tasks.

Tip: Use the Iteration History tab to observe the optimization progress in real time.

- Optional:

Open the Iteration History tab and observe the optimum

solution.

Figure 5.