OS-T: 1300 Direct Frequency Response Analysis of a Flat Plate

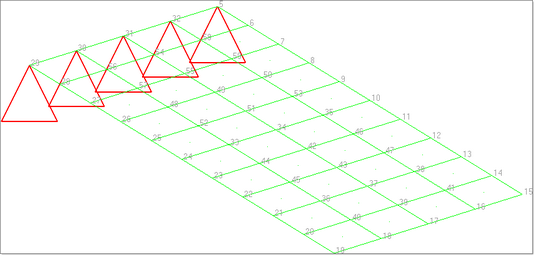

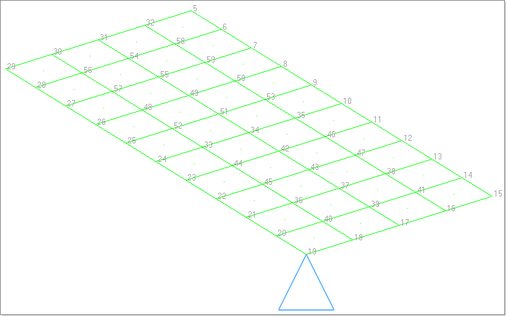

This tutorial demonstrates how to import an existing FE model, apply boundary conditions, and perform a finite element analysis on a flat plate.

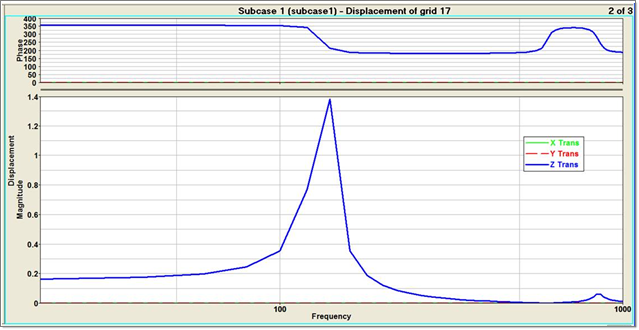

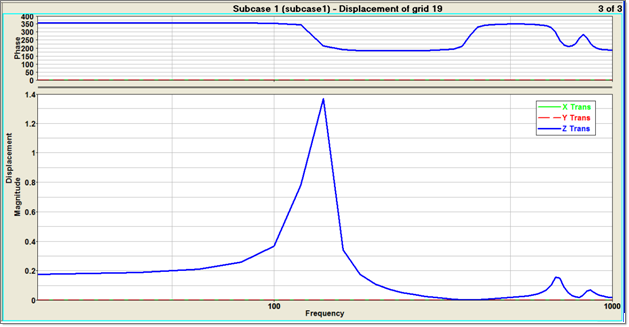

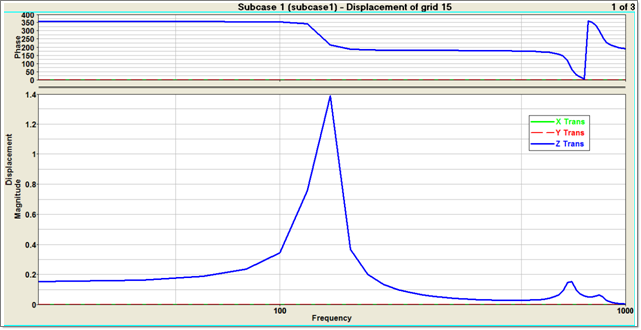

The flat plate is subjected to a frequency-varying unit load excitation using the direct method. Post-processing is done in HyperView and HyperGraph to visualize deformations, mode shape response, and frequency-phase output characteristics.

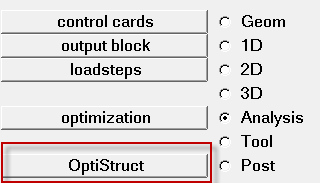

Launch HyperMesh and Set the OptiStruct User Profile

Import the Model

Set Up the Model

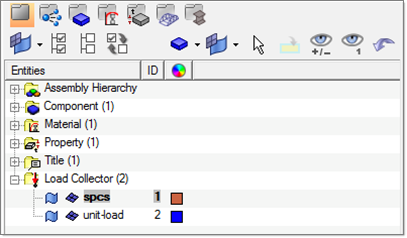

Apply Loads and Boundary Conditions

Create Constraints

Create a Unit Load at a Point on the Flat Plate

Create a Frequency Range Table

Create a Frequency Dependent Dynamic Load

Create a Set of Frequencies

Create a Load Step

Create a Set of Nodes

- In the Model Browser, right-click and select .

- For Name, enter SETA.

- For Card Image, select None.

- Leave the Set Type switch set to non-ordered type.

- For Entity IDs, select Nodes from the selection switch.

- Click Nodes and select nodes with IDs 15, 17 and 19.

- Click proceed.

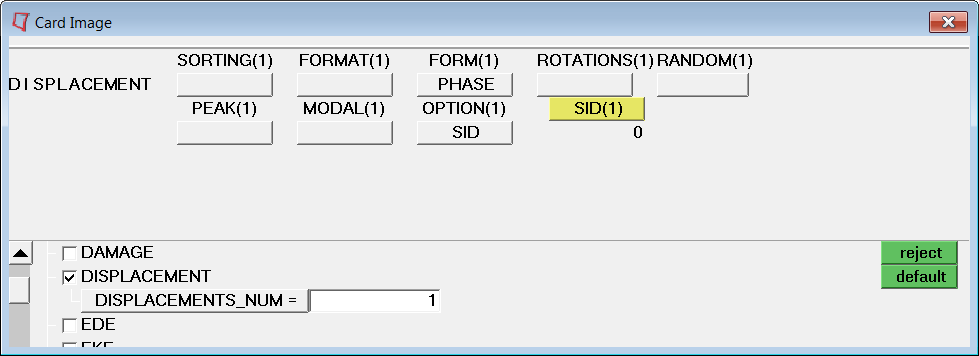

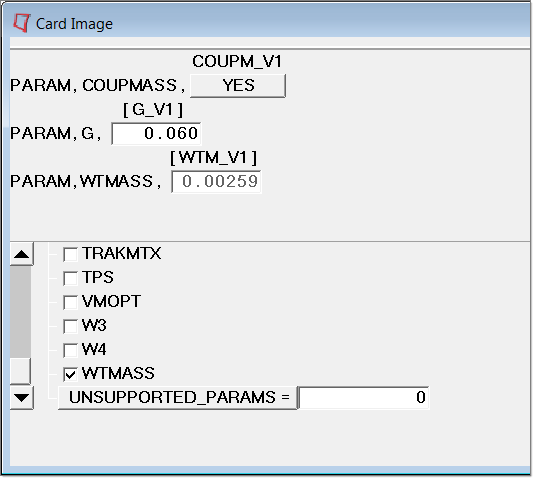

Create a Set of Outputs and Mass Factors

Submit the Job

- flat_plate_direct_response.html

- HTML report of the analysis, providing a summary of the problem formulation and the analysis results.

- flat_plate_direct_response.out

- OptiStruct output file containing specific information on the file setup, the setup of your optimization problem, estimates for the amount of RAM and disk space required for the run, information for each of the optimization iterations, and compute time information. Review this file for warnings and errors.

- flat_plate_direct_response.h3d

- HyperView binary results file.

- flat_plate_direct_response.res

- HyperMesh binary results file.

- flat_plate_direct_response.stat

- Summary, providing CPU information for each step during analysis process.

View the Results

This step describes how to view displacement results (.mvw file) in HyperGraph and also explains the displacement output (.disp file) from this run.

.

.

.

.

and enter information in the

pop-out window.

and enter information in the

pop-out window.

.

.