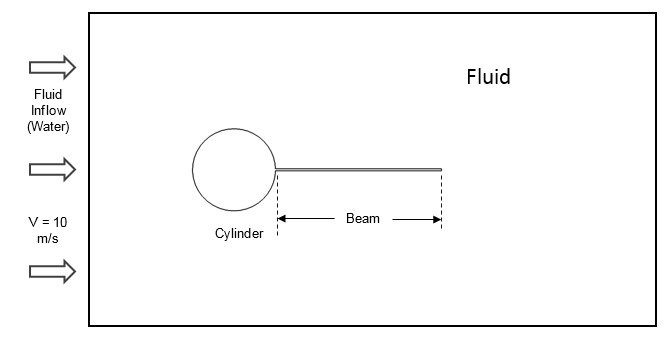

OS-T: 1600 Fluid-Structure Interaction Analysis of Piezoelectric Harvester Assembly

The purpose of this tutorial is to demonstrate how to carry out Fluid-Structure Interaction analysis that is, with OptiStruct nonlinear transient analysis coupling within AcuSolve fluid dynamic analysis.

Figure 1. Schematic of the Problem

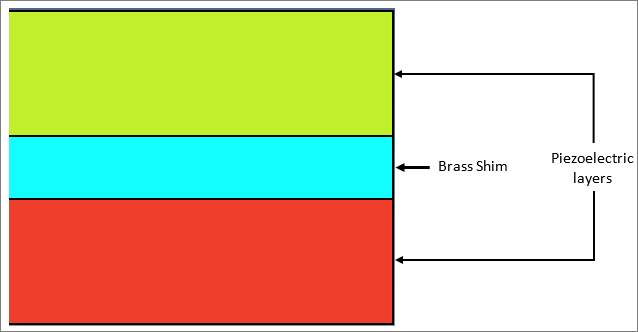

Figure 2. Various Layers of Beam

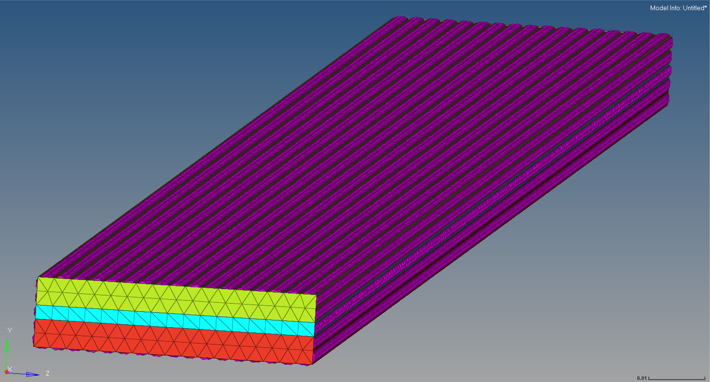

The AcuSolve fluid model (slab_dcfsi.inp) and the OptiStruct structural beam model (Slab.fem) are located in the fsi_models.zip file. Refer to Access the Model Files.

Launch HyperMesh and Set the OptiStruct User Profile

Import the Model

Set Up the Model

Create Contact Surface

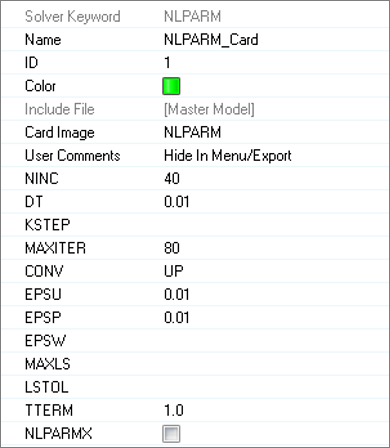

Define Nonlinear Parameters

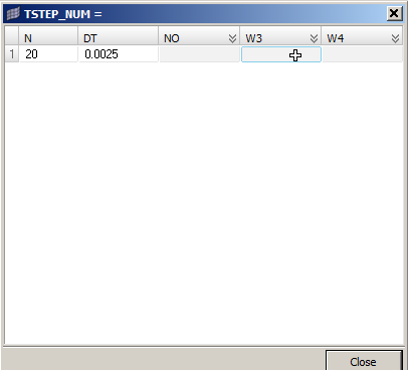

Define Transient Time Step Parameters

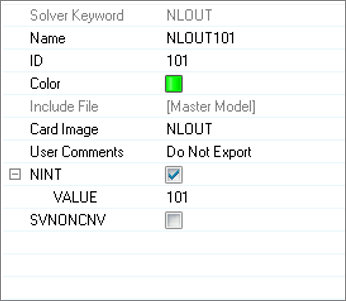

Define Incremental Result Output for Nonlinear Analysis

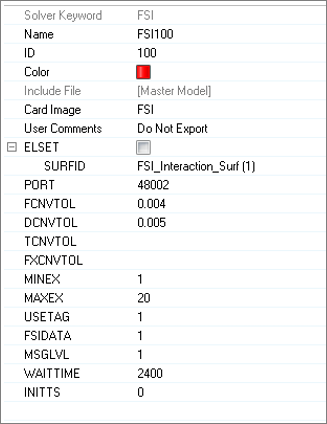

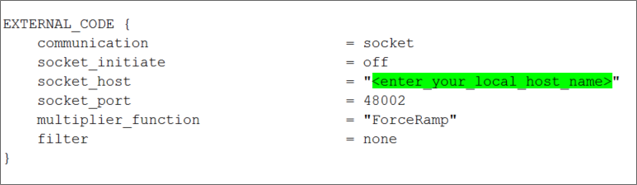

Define Fluid-Structure Interaction Parameters

Define Output Control Parameters

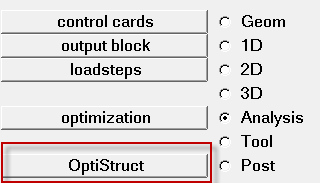

- From the Analysis page, select control cards.

- Click GLOBAL_OUTPUT_REQUEST.

- For DISPLACEMENT, ELFORCE, OLOAD, STRESS, and STRAIN, set Option to Yes.

- Click return twice to go to the main menu.

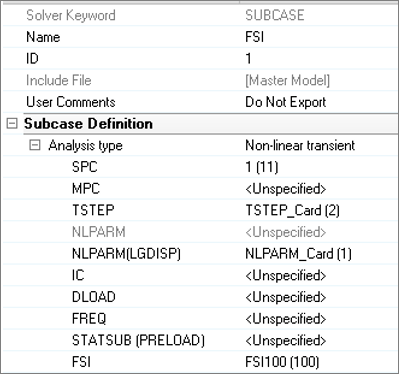

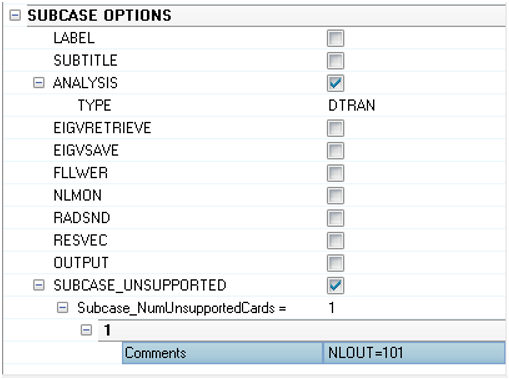

Create Nonlinear Transient Analysis Subcase

Submit the Job

Initiate a Run

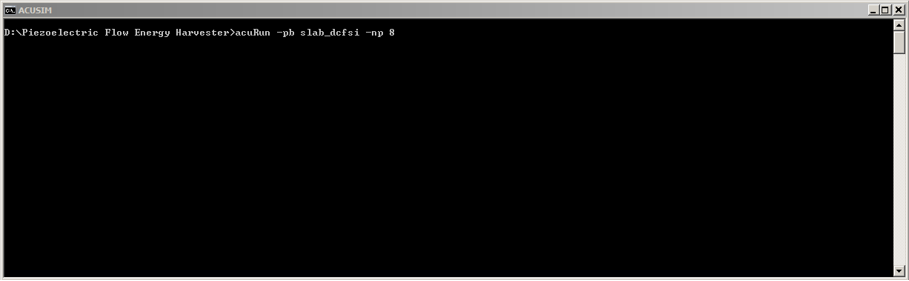

Submit the AcuSolve Job

- cci.txt

- Contains information pertaining to model progression. Logs regarding connection establishment, initial external code handshake and subsequent time step data in conjunction with exchange/stagger.

- Slab.html

- HTML report of the analysis, giving a summary of the problem formulation and the analysis results.

- Slab.out

- ASCII based output file of the model check run before the simulation begins and gives some basic information on the results of the run.

- Slab.stat

- Summary of analysis process, providing CPU information for each step during the process.

- Slab.h3d

- HyperView compressed binary results file.

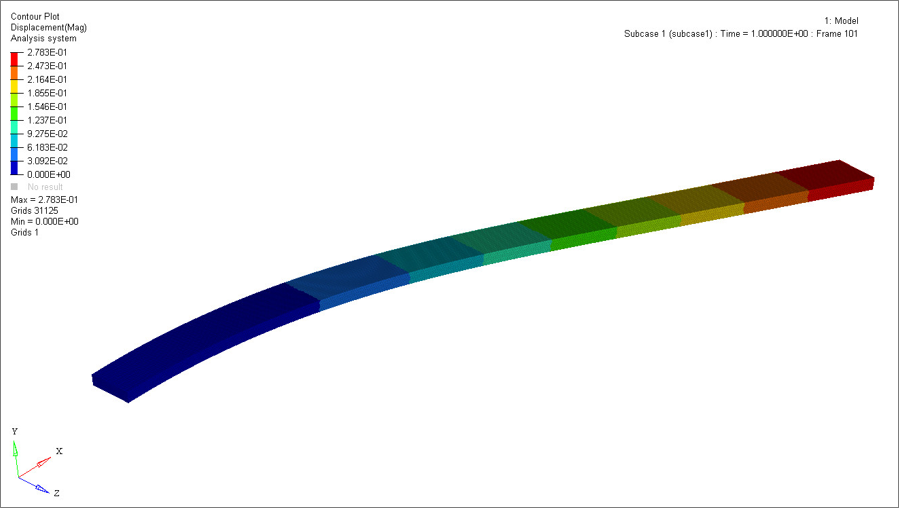

View the Results

Figure 14.

.

.

and input the values, as shown in

and input the values, as shown in