Tavares UFRJ Breakage Model

Model Overview

This model captures the various body breakage mechanisms that occur during particle collisions. Specifically, it describes the adaptation of a detailed breakage mechanism of brittle materials and accounts for the variability and size-dependency in breakage probability and weakening by repeated stressing and delivers the final size distribution of the material. The nature of the failure mechanisms is governed by the material properties and the nature of the stress field around and within individual particles. Specifically, the model is comprised of mathematical expressions that describe the critical condition for failure of a particle and once this critical condition is met during a DEM simulation, the particle is instantaneously replaced by a family of spheres with smaller sizes. Furthermore, an innovative approach has been implemented that handles the particle replacement eliminating potential mass loss.

The model is available as interactions between:

- Particle to Particle,

- Particle to Geometry

- Particle Body Force and requires importing its own factory particle through EDEM’s interface.

Body breakage

Calculation cycle

During comminution, particles of a given material suffer impacts with a magnitude lower than the level required to break. However, the repeatability of impacts can result in energies sufficient to cause internal crack-like damage on the particle, leading in its weakening and making it more amenable to break in a future stressing event. Therefore, subsequent impacts with energy smaller than the original particle fracture energy can lead to breakage. This effect is called Particle Damage Accumulation (Tavares 2002 and Tavares 2009).

After the material is set up with the use of relevant parameters, EDEM detects impacts and calculates the energy absorbed from each impact event. The recorded impact energy is assigned accurately to each element involved in the collision based on their stiffnesses and it is compared with the stored fracture energy of the particle. If the first is smaller than the latter, then the particle will not break, instead it will suffer damage that will subsequently create a new fracture energy to the particle, which will be lower than the previous one.

Figure 1 demonstrates the cycle that the particle undergoes during impact. The blue route refers to the damaging and weakening of the particle, whereas the red route refers to the body breakage and subsequent replacement of the initial particle (mother particle) by its fragments.

Furthermore, being a model in which the critical condition is based on energy it is less sensitive to the choice of either coefficient of restitution or stiffness values during the simulation, than a force or a stress-based model. The stressing energy is given by the combination of the normal and shear energies, given by:

| (1) |

where En, Et are the normal and shear energies, respectively and ct is the fraction of the shear energy that contributes to the collision energy and which may vary with impact angle.

Although the breakage probability and weakening were originally developed in the form of continuous distributions, being particle-based, they are directly amenable to be adapted to describe populations of discrete particles in DEM.

Figure 1 – Calculation cycle of Particle Damage and Fragmentation due to impact

Particle Replacement Method (PRM)

The particle replacement method employed in the model uses previous established research from the Federal University of Rio de Janeiro and also includes an innovative approach that has been developed in house with close collaboration with the Federal University of Rio de Janeiro and the University of Edinburgh.

The main condition for a particle to break and be replaced by its fragments requires the specific impact energy to be higher than the specific fracture energy of the particle. Unlike breakage probability, adapting the continuous breakage distribution model to a discrete one is a very challenging task, since the original breakage model was developed on the basis of average information on fragments distribution as well as on median values of fracture energies of particles.

The extent of breakage of the fragments is represented by a single parameter, t10, which reflects the proportion of fragments that are finer than 1/10th of the parent particle size (Napier-Munn 1996, Tavares 2008). Details about this can also be found in Tavares and das Neves (2008), Saeidi et.al. (2016). Figure 2 demonstrates the replacement of a mother particle by its fragments.

In order to resemble the outcome of a real breakage event, in which the fines are concentrated close to the point of application of stresses, spheres inside the parent particle are arranged so that the largest fragments overlap in perpendicular direction to the stress that caused breakage. The remaining finer fragments are then arranged in the remaining voids, often also overlapping with the coarser fragments, as illustrated in Figure 2.

Figure 2 – Replacement of the mother particle (left) by a distribution of fragments (right).

During replacement, the fragments are allowed to overlap initially to fit inside the original mother particle volume. Such overlaps between fragments can be substantial resulting in large artificial repulsive forces between them. To control potential explosions between fragments a sophisticated approach has been implemented herein in which a damping rule is used to cap the total contact force applied to each fragment (global damping strength), as well as the duration over which the reduced force is applied (global damping time). Furthermore, based on Griffith’s theory (Sun and Jin 2012) the model also controls the reduction of the artificial overlap between fragments in order to account for the energy dissipation during internal fracturing.

Therefore, a fraction of this overlap can be defined (local damping strength) such that part of the fracture energy is released back to the fragments. This method uses advanced principles of contact mechanics and gives the freedom to the user to control the kinematics of the fragments and prevent the appearance of extremely high velocities of the fragments which would make simulations unrealistic. If any of the global parameters is zero, then this damping step is not applied to the fragments. Figure 3 describes schematically the application of damping both at the contact (local) and the particle (global) level.

Figure 3 – Damping on the contact level (left) and Damping on the particle level (right).

Explanation of parameters

Each particle has a specific fracture energy, which is assigned based on its size, mean value and standard deviation. This energy will vary according to the upper-truncated lognormal distribution (Tavares 2002) given by

| (2) | ||

|

(3) |

where E is the particle fracture energy distribution corresponding to the maximum stressing energy that it can sustain in a collision, Emax is the upper truncation value of the distribution, and E50, σ are the median and standard deviation of the distribution, respectively. The median specific fracture energy of the particle is given by:

| (4) |

where E∞, do, and φ are model parameters that must be fitted to experimental data and dp is the representative particle size contained in the size class and kst is the stiffness of steel (230GPa). It should be noted that if the surface is a geometry then its elasticity must be close to the value of the real material used for the physical testing. If the particle elasticity is scaled then the geometry’s elasticity should be scaled accordingly, to maintain the ratio between the two.

Table 2 summarizes the aforementioned data. Values of φ were found to vary below one and about 2.5. The residual particle fracture energy of minerals E∞ is generally found to be consistently lower than that of ores and rocks, which indicates the higher toughness of the latter. Also, the characteristic size do is significantly coarser for minerals than polycrystalline materials, such as ores and rocks, which reflects the finer microstructures of the latter (Tavares 2007).

In the case where the particle does not break, it will suffer damage that subsequently create a new fracture energy to the particle, lower than the previous one. This new fracture energy will be an intrinsic property of the particle until the next damage event and is given by:

| (5) | ||

|

(6) |

where Ef is the fracture energy of the particle, D is the damage, eEk is the specific stressing energy (or effective impact energy) involved in the collision, and γ is the damage accumulation coefficient, which characterizes the amenability of a material to sustain damage prior to catastrophically breaking. Finally, e is the proportion of energy involved in a collision and which is allocated to the particles based on their stiffness. This is given by

| (7) |

where kp is the particle stiffness, ks is the stiffness of the surface in contact with the particle. In case of a collision involving two particles of the same material, Equation (7) gives e=0.5, since the energy will be equally shared between them.

Table 1 summarizes all the input parameters of the model. Emin is the minimum impact energy. It is considered such that all impact events below that level have negligible effect on the particles, thus they can discard. A default value is suggested to be 1e-4.

| Symbol | Name |

| γ | Damage constant |

| Global Damping Time | Percentage of total contact force upon the particle (%) |

| Global Damping Strength | Duration of global damping strength upon the particle (sec) |

| E∞ | E50 parameter (J/kg) |

| d0 | E50 parameter (mm) |

| ϕ | Fitting parameter |

| σE | Standard deviation of the fracture energy |

| A | Impact breakage parameter used in the calculation of the t10 |

| b | Impact breakage parameter used in the calculation of the t10 |

| dmin | Minimum particle size for breakage (mm) |

| Emin | Minimum collision energy (J) |

| Ct | Fraction of shear energy |

| Truncation ratio | Upper limit of fracture energies |

Table 1 List of parameters used in the Tavares UFRJ Breakage model.

The extent of breakage of the fragments can be represented by the single parameter, t10, which represents the proportion of fragments that are finer than 1/10th of the parent particle size (Napier-Munn et al., 1996; Tavares, 2007). Tavares, 2009 proposed that the extent of breakage when stressing a batch of particles is related to the specific stressing energy and the median fracture energy of the particles using the following expression

| (8) |

where A and b are impact parameters fitted to experimental data, in which A corresponds to the maximum value of t10 that can be achieved when breaking a material in a single impact event. The higher the specific impact energy Ek in comparison to the specific fracture energy of the particles, the higher the value of t10 and the finer the progeny size distribution. By using the median specific fracture energy of the particles that underwent breakage, Equation (8) is able to account for the particle size effect in breakage (Tavares 2009).

To accurately simulate breakage of spherical particles in DEM requires the definition of the progeny size distribution in which the parent particle will be replaced. In order to deal with this, Tavares and Chagas (2020) recently proposed standard families of progeny fragments that were obtained on the basis of compiling breakage data of 40 materials, coupled to a procedure that uses Monte Carlo simulations to draw each of them when a particle breaks. As such, families of progeny size distributions have been proposed for a variety of discrete values of t10. The aforementioned families have been prepared such that the mass loss or gain is eliminated each time a parent particle is replaced by its fragments (no more than 1%).

To eliminate the mass loss and provide accurate size distributions, while maintaining simulation efficiency, a size class has been created, called dummy particles, which describes fragments down to 1/5th of the parent size. The particles contained in this dummy size class are not allowed to suffer breakage. In addition to that, since these particles represent the smallest grains, they can also considered to be more deformable than particles contained in the remaining size classes, hence a lower value of stiffness may be used for them. This is done through the EDEM GUI by creating a new material and naming its particle as “dummy_particle” with lower elasticity for this particular size class. This would be particularly beneficial in the case of confined systems, where such particles would not contribute as readily to the raise of stresses in the system.

Outputs in EDEM

The breakage model provides a list of outputs related with the weakening of the particles and their related energies during weakening, as well as the body breakage and the final size distribution of the fragments. The outputs of the breakage model are the following:

- New fracture energy per particle type

- Fragment size distribution

Calibration tests

Materials can break either by high impact forces or by low-energy stressing events. The fundamental properties of the fracture process can be studied most effectively by well-controlled experiments on single particles and/or small volumes of material thus suitable calibration tests have been designed over the years.

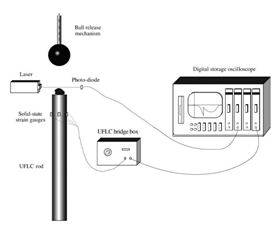

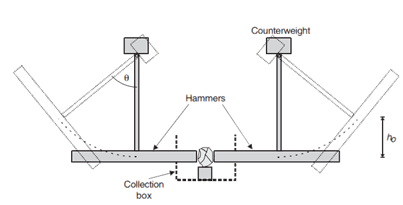

The traditional approaches to measure the fracture characteristics of particles under repeated impacts include drop weights tests and the Hopkison bar. A more sophisticated method, that is the result of the hybridization of the aforementioned standard approaches, is the Ultra Fast Load Cell (UFLC – Fig.2), where steel balls strikers are dropped from various heights with the aim to produce desired impact energies (King and Bourgeois 1993, Tavares and King 1998, Tavares and King 2002). The advantage of this method over others is the fact that it contains no empirical constants in the calculation of the overall deformation between contacts, therefore absolute calibration is possible.

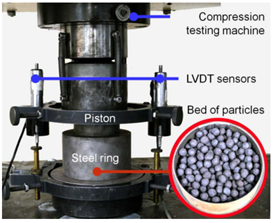

Alternative single-particle tests include slow compression tests (using uniaxial compression presses and pendulum tests), drop-weight loading and ballistic impact loading. Each of these methods allows investigation over a restricted range of strain rate and, because the size distribution of the progeny is dependent on the strain rate, the experimental method must be carefully chosen (Tavares, 2007).

Figure 4 – Schematic of the (a) UFLC Tavares 2002, (b) experimental setup by Barrios et.al. (2015) and (c) a standardized apparatus by Bond (1946).

The following table provides a list of different materials and the description of their breakage parameters provided by literature (Tavares, 2007 and de Carvalho, 2013). These were measured from the calibration tests described above.

| d0 (mm) | E∞ (J/kg) | ϕ (-) | σE | γ | A (%) | b' | dmin (mm) | Emin (J) | |

| Copper Ore | 400 | 60 | 0.45 | 0.4 | 5 | 67.7 | 0.029 | User defined | 10-4 (default) |

| Granulite | 1.1 | 130.7 | 1.99 | 0.9 | 5.4 | 47.5 | 0.027 | User defined | default |

| Limestone 1 | 100 | 7 | 0.8 | 0.39 | 5.4 | 53.3 | 0.033 | User defined | default |

| Limestone 2 | 0.79 | 150 | 1.3 | 0.3 | 5 | 63.4 | 0.033 | User defined | default |

| Iron Ore 1 | 4.3 | 44.9 | 1.28 | 0.46 | 3 | 60.4 | 0.051 | User defined | default |

| Iron Ore 2 | 20.1 | 16.8 | 0.84 | 0.4 | 5 | 44.2 | 0.029 | User defined | default |

| Apatite | 19.3 | 1.05 | 1.62 | User defined | User defined | 45.4 | 0.0115 | User defined | User defined |

| Kalsruhe quartz | 3.48 | 43.4 | 1.61 | User defined | User defined | 38.8 | 0.0176 | User defined | User defined |

| Uintah Basin gilsonite | 7.07 | 5.5 | 1.6 | User defined | User defined | User defined | User defined | User defined | User defined |

| Paragominas bauxite | 14.6 | 70.3 | 0.91 | User defined | User defined | User defined | User defined | User defined | User defined |

| Bingham Canyon copper ore | 1.17 | 96.1 | 1.26 | User defined | User defined | 44.8 | 0.0263 | User defined | User defined |

| Cyprus Sierrita copper ore | 1.37 | 170.9 | 1.41 | User defined | User defined | 58.9 | 0.0204 | User defined | User defined |

| IOCC iron ore | 1.08 | 47.3 | 2.3 | User defined | User defined | 65.4 | 0.0932 | User defined | User defined |

| Santa Luzia gneisse | 2.78 | 48.7 | 1.82 | User defined | User defined | 54.8 | 0.0274 | User defined | User defined |

| Vigne´ sienite | 101 | 26.5 | 0.67 | User defined | User defined | 66.2 | 0.0146 | User defined | User defined |

| Utah marble | 0.882 | 45.9 | 1.76 | User defined | User defined | 76.3 | 0.0792 | User defined | User defined |

Table 2 Measured breakage parameters for various materials.