OS-V: 0900 Constant Amplitude Stress-Life Analysis

A notched test specimen is subjected to tensile loading and a Constant Amplitude Stress-Life Analysis is performed using OptiStruct.

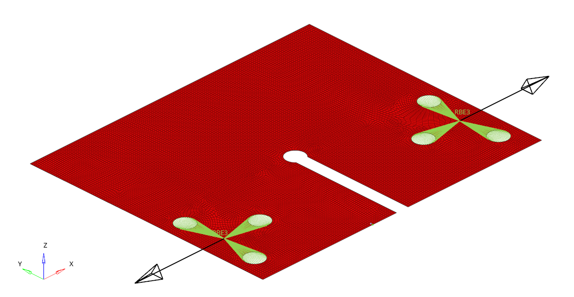

Figure 1. Model with Loading Conditions

Benchmark Model

The model is a test specimen of thickness 9.5mm, subjected to tensile loading of 1150 N at circular holes, normal to the notch. The model was meshed with first-order shell elements and the loading is applied to RBE3 elements that are connected to the holes. The Signed von Mises (SGVON) combined stress was used.

- Material Properties

- Value

- Young's modulus

- 203000 MPa

- Poisson's ratio

- 0.3

- Ultimate tensile strength (UTS)

- 863.0 MPa

- Fatigue strength coefficient (SRI1)

- 1101.0 MPa

- First fatigue strength exponent (B1)

- -0.075

- Cycle limit of endurance for one segment SN curve (NC1)

- 1000000 cycles

- Time Points

- Load Curve Point

- 0

- 0.0

- 1

- 1.0

- 2

- 0.0

- 3

- -1.0

- 4

- 0.0

Figure 2. Load Curve used in FATLOAD

All the modifying factors (Surface Roughness and Fatigue Strength Reduction factor) are set to 1.0.

Results

| Result | eFatigue (Target Value) |

OptiStruct | Normalized with the Target Value |

|---|---|---|---|

| Life (Nf) | 152000 cycles | 151881 cycles | 1.0008 |

Model Files

Refer to Access the Model Files to download the required model file(s).

The model file used in this problem includes:

stress_life_fatigue.fem