Version: September 2011 Edition

List of Classification Parameters

Evaluation Distance

Reference distance to find the evaluation location from the weld element

at which the stress values are extracted.

Weld Width

Width of the weld material from the web wall. This parameter is ignored

if specifying the evaluation distance is done manually.

Grinding Bonus

Parameter to specify if the grinding bonus has to be considered or

not.

Effective Weld Thickness

This parameter is used to consider the influence of welds which do not

cover the same cross section area as indicated by the shell element in

the respective evaluation location. It modifies the stress at the

evaluation location based on the ratio to the shell thickness. (a >

0)

A

r

=

T

i

·

T

f

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyqaiaadk

hacqGH9aqpcaWGubWaaSbaaSqaaiaadMgaaeqaaOGaeS4JPFMaamiv

amaaBaaaleaacaWGMbaabeaaaaa@3F13@

T

i

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamivaabaaa

aaaaaapeGaamyAaaaa@37DA@

: Thickness influence represents

the resultant maximum weld thickness. It varies based on the

weld type. this parameter is location specific.

T

f

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaaeaaaaaaaaa8

qacaWGubGaamOzaaaa@37D7@

: Indicates which shell thickness

you need for the calculation of effective weld thickness ( a ).

Valid options are t and tmin , also location specific.

t = thickness of welded shell. tmin = min thickness

of all connected shells.

Mean Stress Sensitivity – Normal

Mean stress sensitivity factor used for the normal direction

evaluation.

Mean Stress Sensitivity – Shear

Mean stress sensitivity factor used for the shear direction

evaluation.

Notch Class - Transverse Location_X

Notch class definition considered for the fatigue limit calculation for

the normal stress component in the transverse direction (perpendicular

to the axis of the weld) at ‘X’.

Notch Class - Longitudinal Location_X:

Notch class definition considered for the fatigue limit calculation for

the normal stress component in the longitudinal direction (parallel to

the axis of the weld) at ‘X’.

Notch Class - Shear Location_X

Notch class definition considered for the shear stress component at

‘X’.Note: Where ‘X’ can be any evaluation location.

Material Yield - Location_X

Material yield value used for the static evaluation.

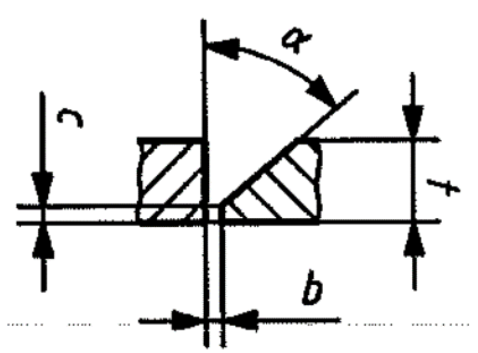

Groove Gap (b)

Gap between the two plates at the location of weld. b in Figure 1 .

Groove Depth (h)

Height of the groove from the top, calculated as t - c from Figure 1 .

Groove Angle (alpha - deg)

Angle of the groove/plate walls at the location of weld. a in Figure 1 .

Figure 1.

Formulation

Stress Component considered for evaluation

σT : Transverse component perpendicular to the axis of the

weld

σL : Longitudinal component parallel to the axis of the

weld

τ: Shear Component

Corrected stress calculation

The stress value correction is carried out using the effective weld

thickness.

Calculation of the Assessment stress value (numerator in utilization

formulae)

σTA (Stress Amplitude) = (σTmax -

σTmin ) / 2The stress amplitude is used as the

numerator for the utilization calculation.

Fatigue Limit Calculation

The fatigue limit values (σTzul , σLzul , and

τzul ), are calculated based on the following regimes of

Stress Ratio ®,

Reference: the DVS1608 regulation document section 7.2.2.

For nominal stress (longitudinal σLzul and transverse

σTzul )

Regime 1:

R

σ

> 1

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaWaaeWaaeaaqa

aaaaaaaaWdbiaadkfapaWaaSbaaSqaa8qacqaHdpWCa8aabeaak8qa

cqGH+aGpcaqGGaGaaGymaaWdaiaawIcacaGLPaaaaaa@3D1F@

σ

z

u

l

=

54

⋅

1.04

−

x

M

P

a

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVCI8FfYJH8YrFfeuY=Hhbbf9v8qqaqFr0xc9pk0xbb

a9q8WqFfeaY=biLkVcLq=JHqpepeea0=as0Fb9pgeaYRXxe9vr0=vr

0=vqpWqaaeaabiGaciaacaqabeaadaqaaqaaaOqaaabaaaaaaaaape

Gaeq4Wdm3damaaBaaaleaapeGaamOEaiaadwhacaWGSbaapaqabaGc

peGaeyypa0JaaGynaiaaisdacqGHflY1caaIXaGaaiOlaiaaicdaca

aI0aWdamaaCaaaleqabaWdbiabgkHiTiaadIhaaaGcdaqadaWdaeaa

peGaamytaiaadcfacaWGHbaacaGLOaGaayzkaaaaaa@4951@

Regime 2:

−

∞

≤

R

σ

≤

0

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaWaaeWaaeaaqa

aaaaaaaaWdbiabgkHiTiaabccacqGHEisPcaqGGaGaeyizImQaaeii

aiaadkfapaWaaSbaaSqaa8qacqaHdpWCa8aabeaak8qacqGHKjYOca

qGGaGaaGimaaWdaiaawIcacaGLPaaaaaa@43C7@

σ

z u l

= 46 ⋅

1.04

− x

1

1 +

M

σ

1 +

R

σ

1 −

R

σ

M P a

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVCI8FfYJH8YrFfeuY=Hhbbf9v8qqaqFr0xc9pk0xbb

a9q8WqFfeaY=biLkVcLq=JHqpepeea0=as0Fb9pgeaYRXxe9vr0=vr

0=vqpWqaaeaabiGaciaacaqabeaadaqaaqaaaOqaaabaaaaaaaaape

Gaeq4Wdm3damaaBaaaleaapeGaamOEaiaadwhacaWGSbaapaqabaGc

peGaeyypa0JaaGinaiaaiAdacqGHflY1caaIXaGaaiOlaiaaicdaca

aI0aWdamaaCaaaleqabaWdbiabgkHiTiaadIhaaaGcdaqadaWdaeaa

peWaaSaaa8aabaWdbiaaigdaa8aabaWdbiaaigdacqGHRaWkcaWGnb

WdamaaBaaaleaapeGaeq4WdmhapaqabaGcpeWaaSaaa8aabaWdbiaa

igdacqGHRaWkcaWGsbWdamaaBaaaleaapeGaeq4Wdmhapaqabaaake

aapeGaaGymaiabgkHiTiaadkfapaWaaSbaaSqaa8qacqaHdpWCa8aa

beaaaaaaaaGcpeGaayjkaiaawMcaamaabmaapaqaa8qacaWGnbGaam

iuaiaadggaaiaawIcacaGLPaaaaaa@5A39@

Regime 3:

0

<

R

σ

<

0.5

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaWaaeWaaeaaqa

aaaaaaaaWdbiaaicdacaqGGaGaeyipaWJaaeiiaiaadkfapaWaaSba

aSqaa8qacqaHdpWCa8aabeaak8qacqGH8aapcaqGGaGaaGimaiaac6

cacaaI1aaapaGaayjkaiaawMcaaaaa@418F@

σ

z u l

= 42 ⋅

1.04

− x

1

1 +

M

σ

3

1 +

R

σ

1 −

R

σ

M P a

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVCI8FfYJH8YrFfeuY=Hhbbf9v8qqaqFr0xc9pk0xbb

a9q8WqFfeaY=biLkVcLq=JHqpepeea0=as0Fb9pgeaYRXxe9vr0=vr

0=vqpWqaaeaabiGaciaacaqabeaadaqaaqaaaOqaaabaaaaaaaaape

Gaeq4Wdm3damaaBaaaleaapeGaamOEaiaadwhacaWGSbaapaqabaGc

peGaeyypa0JaaGinaiaaikdacqGHflY1caaIXaGaaiOlaiaaicdaca

aI0aWdamaaCaaaleqabaWdbiabgkHiTiaadIhaaaGcdaqadaWdaeaa

peWaaSaaa8aabaWdbiaaigdaa8aabaWdbiaaigdacqGHRaWkdaWcaa

WdaeaapeGaamyta8aadaWgaaWcbaWdbiabeo8aZbWdaeqaaaGcbaWd

biaaiodaaaWaaeWaa8aabaWdbmaalaaapaqaa8qacaaIXaGaey4kaS

IaamOua8aadaWgaaWcbaWdbiabeo8aZbWdaeqaaaGcbaWdbiaaigda

cqGHsislcaWGsbWdamaaBaaaleaapeGaeq4WdmhapaqabaaaaaGcpe

GaayjkaiaawMcaaaaaaiaawIcacaGLPaaadaqadaWdaeaapeGaamyt

aiaadcfacaWGHbaacaGLOaGaayzkaaaaaa@5CC9@

Regime 4:

0.5

≤

R

σ

<

1

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaWaaeWaaeaaqa

aaaaaaaaWdbiaaicdacaGGUaGaaGynaiaabccacqGHKjYOcaqGGaGa

amOua8aadaWgaaWcbaWdbiabeo8aZbWdaeqaaOWdbiabgYda8iaabc

cacaaIXaaapaGaayjkaiaawMcaaaaa@4241@

σ

z u l

= 36.5 ⋅

1.04

− x

M P a

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVCI8FfYJH8YrFfeuY=Hhbbf9v8qqaqFr0xc9pk0xbb

a9q8WqFfeaY=biLkVcLq=JHqpepeea0=as0Fb9pgeaYRXxe9vr0=vr

0=vqpWqaaeaabiGaciaacaqabeaadaqaaqaaaOqaaabaaaaaaaaape

Gaeq4Wdm3damaaBaaaleaapeGaamOEaiaadwhacaWGSbaapaqabaGc

peGaeyypa0JaaG4maiaaiAdacaGGUaGaaGynaiabgwSixlaaigdaca

GGUaGaaGimaiaaisdapaWaaWbaaSqabeaapeGaeyOeI0IaamiEaaaa

kmaabmaapaqaa8qacaWGnbGaamiuaiaadggaaiaawIcacaGLPaaaaa

a@4AC2@

M

τ

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVCI8FfYJH8YrFfeuY=Hhbbf9v8qqaqFr0xc9pk0xbb

a9q8WqFfeaY=biLkVcLq=JHqpepeea0=as0Fb9pgeaYRXxe9vr0=vr

0=vqpWqaaeaabiGaciaacaqabeaadaqaaqaaaOqaaabaaaaaaaaape

Gaamyta8aadaWgaaWcbaWdbiabes8a0bWdaeqaaaaa@38FA@

is the mean stress sensitivity, the

exponent x in the above equations is queried from the below notch detail

tables:

Curve

B

B-

B+

C

C-

C+

D

D-

x

6

7

8

9

10

11

12

13

Curve

E1+

E1

E1-

E4+

E4

E4-

E5+

E5

E5-

E6+

E6

E6-

X

14

15

16

17

18

19

20

21

22

23

24

25

Curve

F1+

F1

F2

x

26

27

28

For shear stress,

τ

z

u

l

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaaeaaaaaaaaa8

qacqaHepaDpaWaaSbaaSqaa8qacaWG6bGaamyDaiaadYgaa8aabeaa

aaa@3B1C@

,

Regime 2:

( − 1 ≤

R

τ

≤ 0 )

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVCI8FfYJH8YrFfeuY=Hhbbf9v8qqaqFr0xc9pk0xbb

a9q8WqFfeaY=biLkVcLq=JHqpepeea0=as0Fb9pgeaYRXxe9vr0=vr

0=vqpWqaaeaabiGaciaacaqabeaadaqaaqaaaOqaaiaacIcaqaaaaa

aaaaWdbiabgkHiTiaaigdacaqGGaGaeyizImQaaeiiaiaadkfapaWa

aSbaaSqaa8qacqaHepaDa8aabeaak8qacqGHKjYOcaqGGaGaaGima8

aacaGGPaaaaa@4235@

τ

z

u

l

=

28

⋅

1.04

−

x

1

1

+

M

τ

1

+

R

τ

1

−

R

τ

M

P

a

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVCI8FfYJH8YrFfeuY=Hhbbf9v8qqaqFr0xc9pk0xbb

a9q8WqFfeaY=biLkVcLq=JHqpepeea0=as0Fb9pgeaYRXxe9vr0=vr

0=vqpWqaaeaabiGaciaacaqabeaadaqaaqaaaOqaaabaaaaaaaaape

GaeqiXdq3damaaBaaaleaapeGaamOEaiaadwhacaWGSbaapaqabaGc

peGaeyypa0JaaGOmaiaaiIdacqGHflY1caaIXaGaaiOlaiaaicdaca

aI0aWdamaaCaaaleqabaWdbiabgkHiTiaadIhaaaGcdaqadaWdaeaa

peWaaSaaa8aabaWdbiaaigdaa8aabaWdbiaaigdacqGHRaWkcaWGnb

WdamaaBaaaleaapeGaeqiXdqhapaqabaGcpeWaaSaaa8aabaWdbiaa

igdacqGHRaWkcaWGsbWdamaaBaaaleaapeGaeqiXdqhapaqabaaake

aapeGaaGymaiabgkHiTiaadkfapaWaaSbaaSqaa8qacqaHepaDa8aa

beaaaaaaaaGcpeGaayjkaiaawMcaamaabmaapaqaa8qacaWGnbGaam

iuaiaadggaaiaawIcacaGLPaaaaaa@5A41@

Regime 3:

(

0

<

R

τ

<

0.5

)

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaaiikaabaaa

aaaaaapeGaaGimaiaabccacqGH8aapcaqGGaGaamOua8aadaWgaaWc

baWdbiabes8a0bWdaeqaaOWdbiabgYda8iaabccacaaIWaGaaiOlai

aaiwdapaGaaiykaaaa@4161@

τ

z u l

= 26.5 ⋅

1.04

− x

1

1 +

M

τ

3

1 +

R

τ

1 −

R

τ

M P a

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVCI8FfYJH8YrFfeuY=Hhbbf9v8qqaqFr0xc9pk0xbb

a9q8WqFfeaY=biLkVcLq=JHqpepeea0=as0Fb9pgeaYRXxe9vr0=vr

0=vqpWqaaeaabiGaciaacaqabeaadaqaaqaaaOqaaabaaaaaaaaape

GaeqiXdq3damaaBaaaleaapeGaamOEaiaadwhacaWGSbaapaqabaGc

peGaeyypa0JaaGOmaiaaiAdacaGGUaGaaGynaiabgwSixlaaigdaca

GGUaGaaGimaiaaisdapaWaaWbaaSqabeaapeGaeyOeI0IaamiEaaaa

kmaabmaapaqaa8qadaWcaaWdaeaapeGaaGymaaWdaeaapeGaaGymai

abgUcaRmaalaaapaqaa8qacaWGnbWdamaaBaaaleaapeGaeqiXdqha

paqabaaakeaapeGaaG4maaaadaqadaWdaeaapeWaaSaaa8aabaWdbi

aaigdacqGHRaWkcaWGsbWdamaaBaaaleaapeGaeqiXdqhapaqabaaa

keaapeGaaGymaiabgkHiTiaadkfapaWaaSbaaSqaa8qacqaHepaDa8

aabeaaaaaak8qacaGLOaGaayzkaaaaaaGaayjkaiaawMcaamaabmaa

paqaa8qacaWGnbGaamiuaiaadggaaiaawIcacaGLPaaaaaa@5E44@

Regime 4:

(

R

τ

≥

0.5

)

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaaiikaabaaa

aaaaaapeGaamOua8aadaWgaaWcbaWdbiabes8a0bWdaeqaaOWdbiab

gwMiZkaabccacaaIWaGaaiOlaiaaiwdapaGaaiykaaaa@3F1F@

τ

z u l

= 24.4 ⋅

1.04

− x

M P a

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVCI8FfYJH8YrFfeuY=Hhbbf9v8qqaqFr0xc9pk0xbb

a9q8WqFfeaY=biLkVcLq=JHqpepeea0=as0Fb9pgeaYRXxe9vr0=vr

0=vqpWqaaeaabiGaciaacaqabeaadaqaaqaaaOqaaabaaaaaaaaape

GaeqiXdq3damaaBaaaleaapeGaamOEaiaadwhacaWGSbaapaqabaGc

peGaeyypa0JaaGOmaiaaisdacaGGUaGaaGinaiabgwSixlaaigdaca

GGUaGaaGimaiaaisdapaWaaWbaaSqabeaapeGaeyOeI0IaamiEaaaa

kmaabmaapaqaa8qacaWGnbGaamiuaiaadggaaiaawIcacaGLPaaaaa

a@4AC0@

M

τ

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVCI8FfYJH8YrFfeuY=Hhbbf9v8qqaqFr0xc9pk0xbb

a9q8WqFfeaY=biLkVcLq=JHqpepeea0=as0Fb9pgeaYRXxe9vr0=vr

0=vqpWqaaeaabiGaciaacaqabeaadaqaaqaaaOqaaabaaaaaaaaape

Gaamyta8aadaWgaaWcbaWdbiabes8a0bWdaeqaaaaa@38FA@

is the mean stress sensitivity, the

exponent x in the above equations is queried from the below notch detail

table:

The grinding bonus and the thickness factor is applied to the

calculated fatigue limit for longitudinal and transverse and just the

thickness factor to the calculated shear fatigue limit.

Utilization Factor Calculation

UT = σTA /

σTzul UL =

σLA /

σLzul

Uτ =

τA / τzul

Resultant Utilization Calculation

U

R

=

(

U

T

)

2

+

(

U

L

)

2

+

(

U

τ

)

2

+ (

U

T

X

U

L

)

2

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyvamaaBa

aaleaacaWGsbaabeaakiabg2da9maakeaabaGaaiikaiaadwfadaWg

aaWcbaGaamivaaqabaGccaGGPaWaaWbaaSqabeaacaaIYaaaaOGaey

4kaSIaaiikaiaadwfadaWgaaWcbaGaamitaaqabaGccaGGPaWaaWba

aSqabeaacaaIYaaaaOGaey4kaSIaaiikaiaadwfadaWgaaWcbaGaeq

iXdqhabeaakiaacMcadaahaaWcbeqaaiaaikdaaaGccqGHRaWkcaGG

OaGaamyvamaaBaaaleaacaWGubaabeaakiaadIfacaWGvbWaaSbaaS

qaaiaadYeaaeqaaOGaaiykaaWcbaGaaGOmaaaaaaa@4FE0@