MV-7022: Front Suspension Spring - MotionSolve and OptiStruct Co-simulation

Introduction

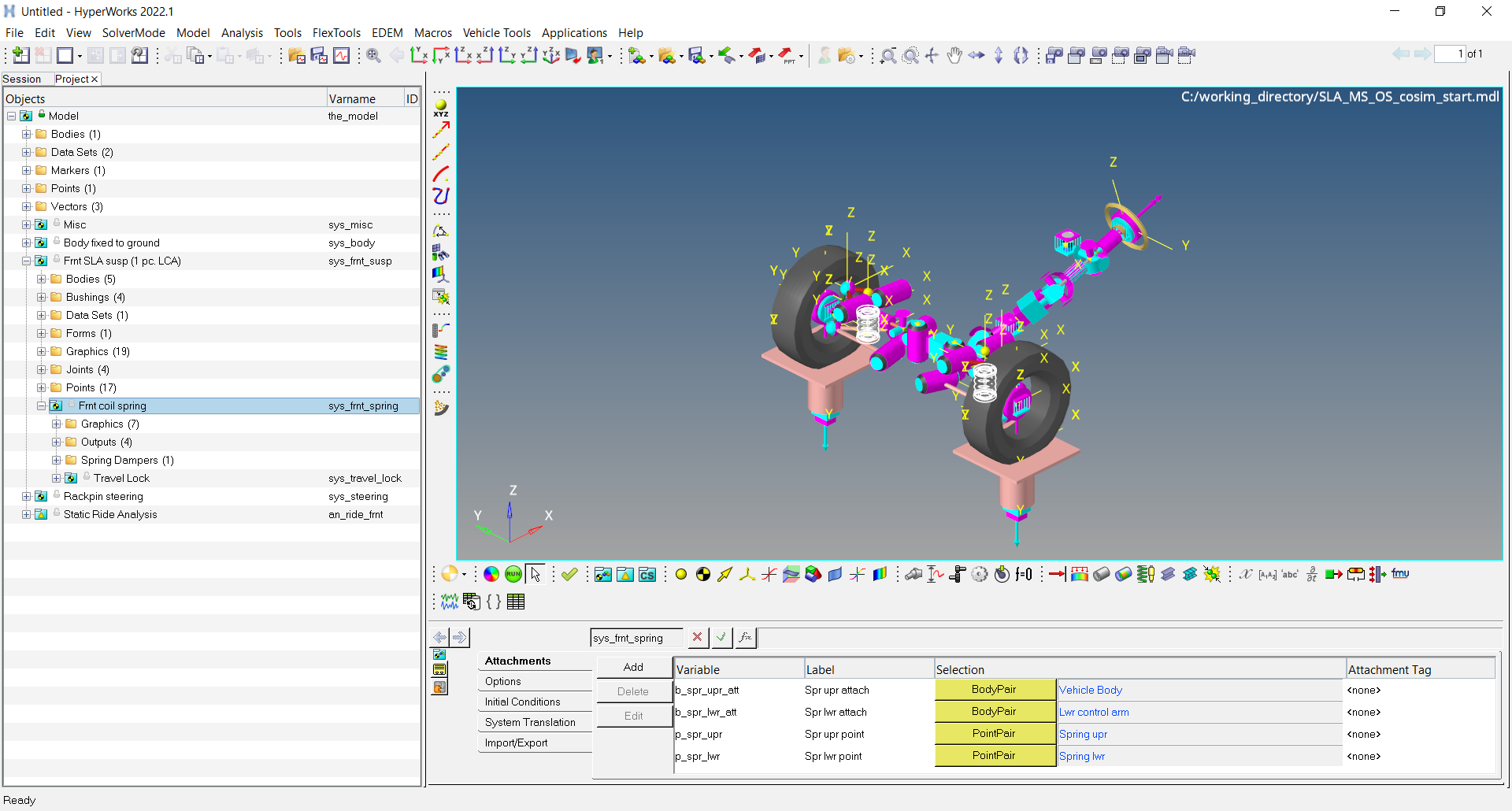

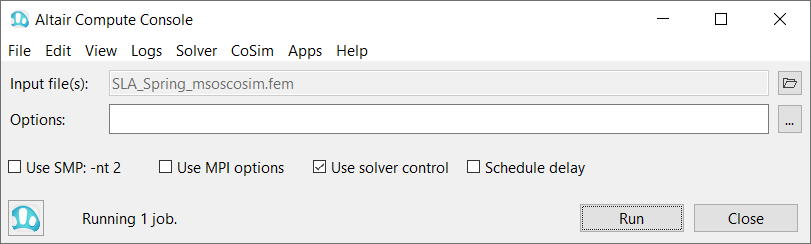

In this tutorial, you will use MotionSolve and OptiStruct in a co-simulation to simulate a spring compression and extension in a short long arms suspension (SLA) system. This tutorial will take approximately one hour to build and one hour to solve.

OptiStruct is a structural analysis solver based on the finite element method for linear and nonlinear structural problems under static and dynamic loadings.

A co-simulation between MotionSolve and OptiStruct can simulate non-linear finite element problems, such as plastic deformation or contact, within a multibody dynamic framework.

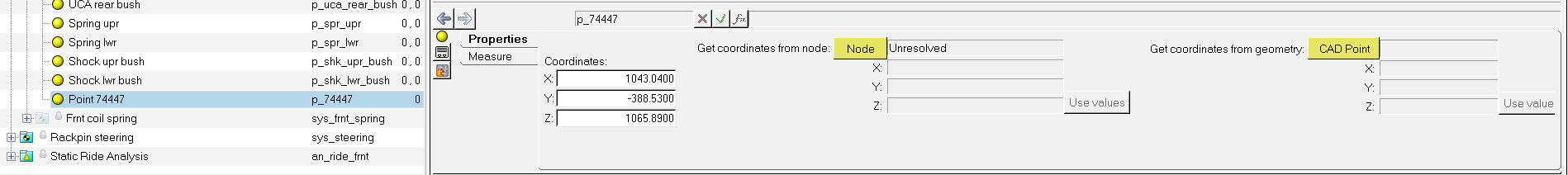

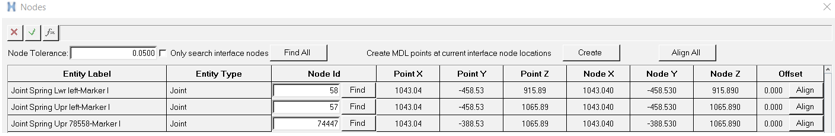

Connections between MotionSolve and OptiStruct are accomplished using interface nodes. The connection type of an interface node is always a spherical joint, meaning only translational displacements and forces are communicated between the two solvers. With a combination of spherical joints, it is possible to model revolute and fixed joint configurations. Currently, other joints are not supported.

- Only one OptiStruct instance can simulate with a MotionSolve instance. However, either instance can entail several flexible bodies.

- Only spherical joints can interact between a MotionSolve and OptiStruct system.

- When connecting several spherical joints with the OptiStruct system, those cannot be subject to a hard constraint on the OptiStruct side. In other words, they cannot be tied together to the same RBE2 or similar entities.

- Any MotionSolve body that is directly connected to a body in OptiStruct should have significant mass and inertia to avoid numerical instabilities. Conversely, this restriction is not required.

- Compliant elements, such as springs, forces, bushings, and so on, that are connected or applied to the OptiStruct body must be defined in OptiStruct. For example, if a bushing acts between a body in MotionSolve and a body in OptiStruct, then the bushing should be modeled in OptiStruct between the interface node and the OptiStruct body.

- The global frame between MotionSolve and OptiStruct need to coincide, the gravitational force needs to act in the same direction, and the units must match.

An intermediate knowledge of MotionView and HyperWorks is required for this tutorial.

Prepare MotionView and Load the Model

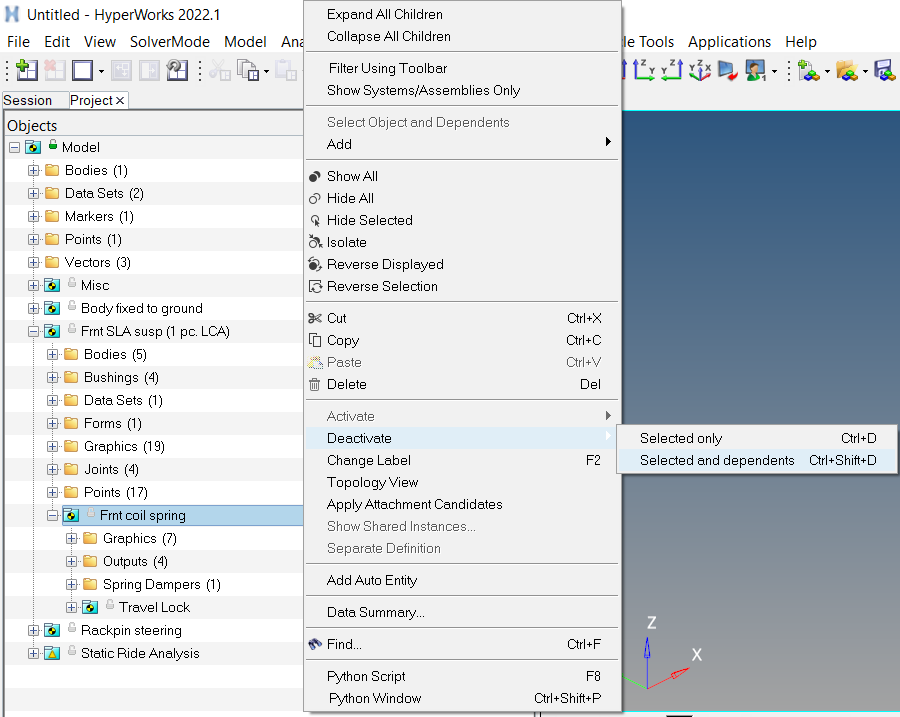

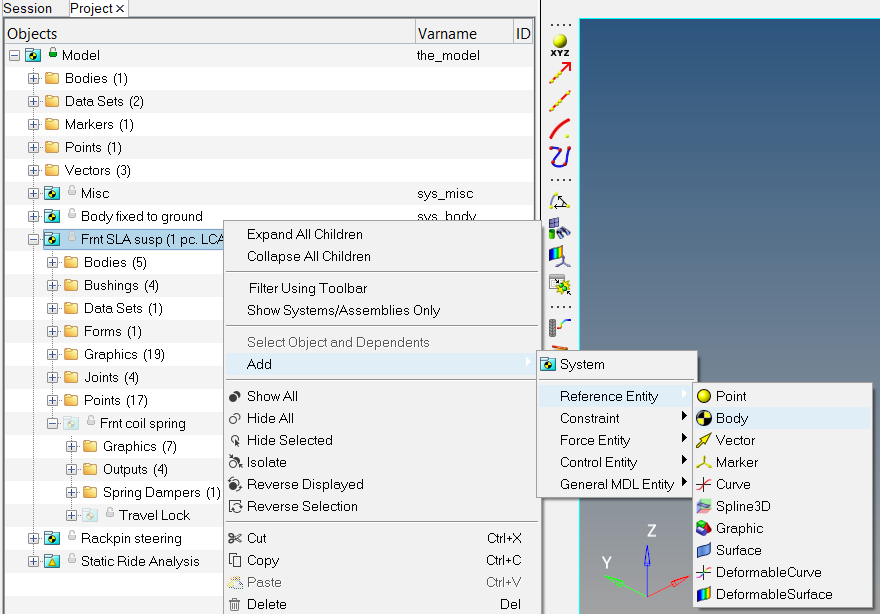

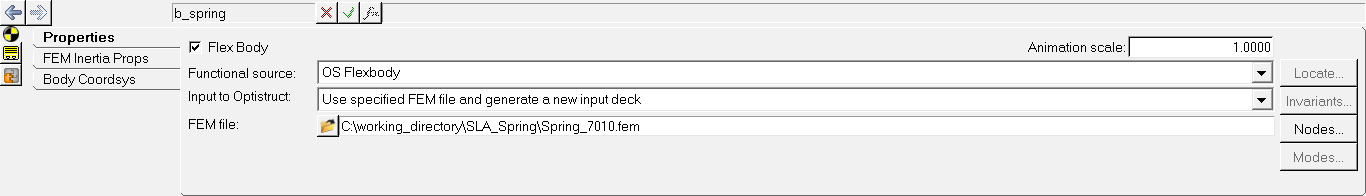

Modify the Model

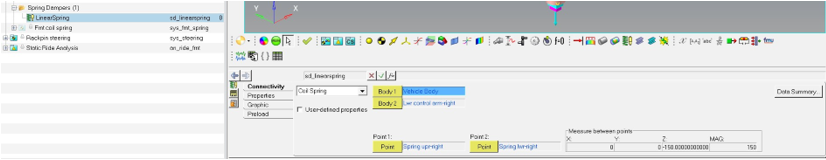

Remove the old springs pairs. Add one OptiStruct-based spring on the left side of the vehicle and a simple linear spring on the right side of the vehicle.