Creating Process Conditions

Use the Process Data tool to create process conditions for the model.

Creating the Exit Surfaces

Exits are where the material exits the domain. The model can have more than one exit surface, and should have at least one exit surface.

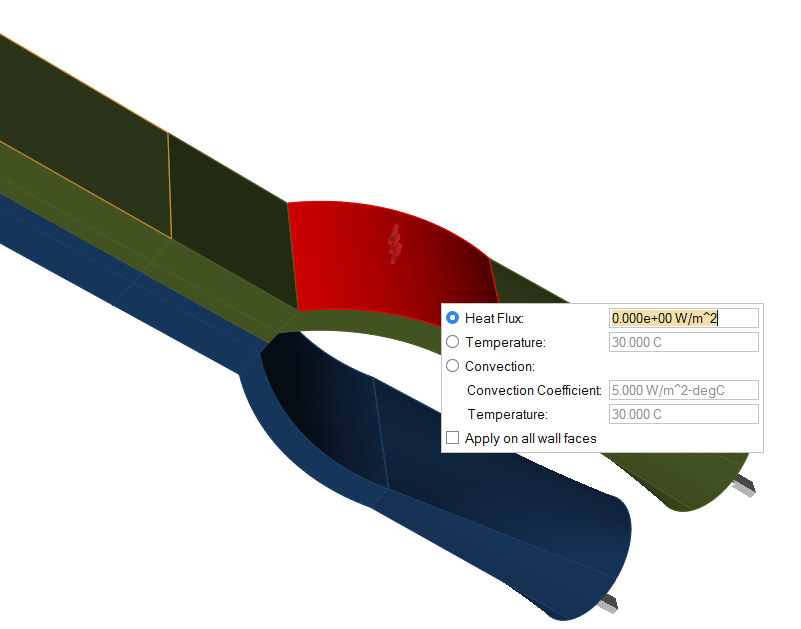

Creating the Wall Surfaces

Walls are used for specifying heat transfer condition.

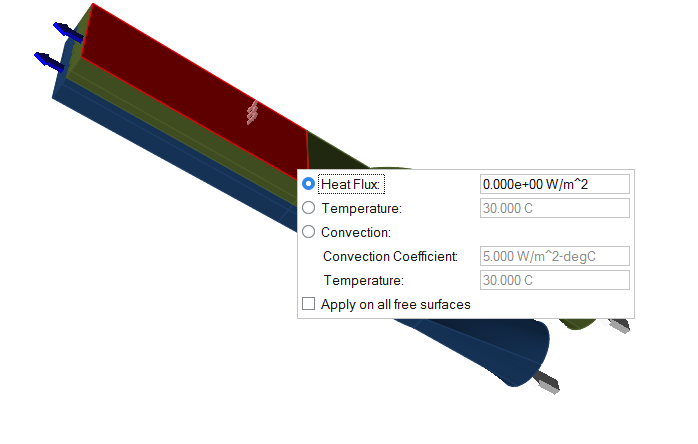

Creating the Free Surfaces

Specify heat transfer data on free surfaces exposed to ambient conditions.

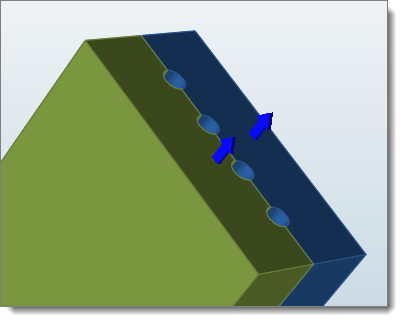

Selecting the Symmetry Surfaces

Symmetry is used for specifying the symmetry planes.

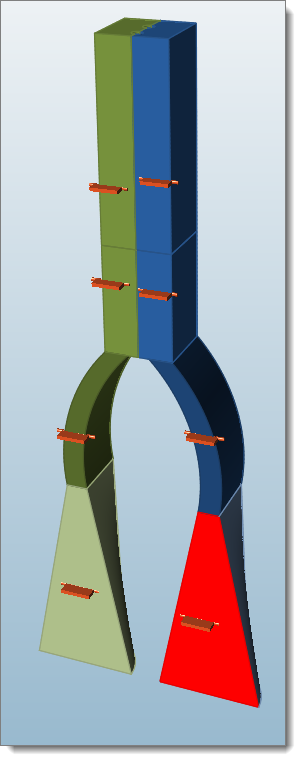

Selecting the Insert Part

If the extrusion has a metal insert, that condition is applied using insert parts. Inserts are modeled using BCs (the interface condition between insert and the polymer).

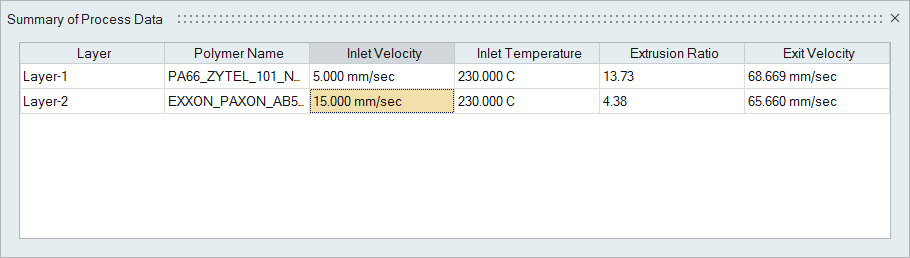

Adjusting Inlet Velocities to Achieve Uniform Exit Velocities

Polymer layers should have uniform exit velocities, which can be balanced by adjusting inlet velocities.

When extruding two or more polymers to create a coextruded part, the exit velocity and temperature conditions should be compatible. Exit velocities of all of the layers should be more or less the same. Temperatures of each layer need not be identical, as they have to be based on the material properties, but should coexist well. This tool will summarize the data to ensure it is compatible and will not affect the product quality and to help the user correct these issues if they arise.