Tutorial: Inspire Friction Stir Welding Model Setup

Set up and complete a friction stir welding analysis and post-process the data.

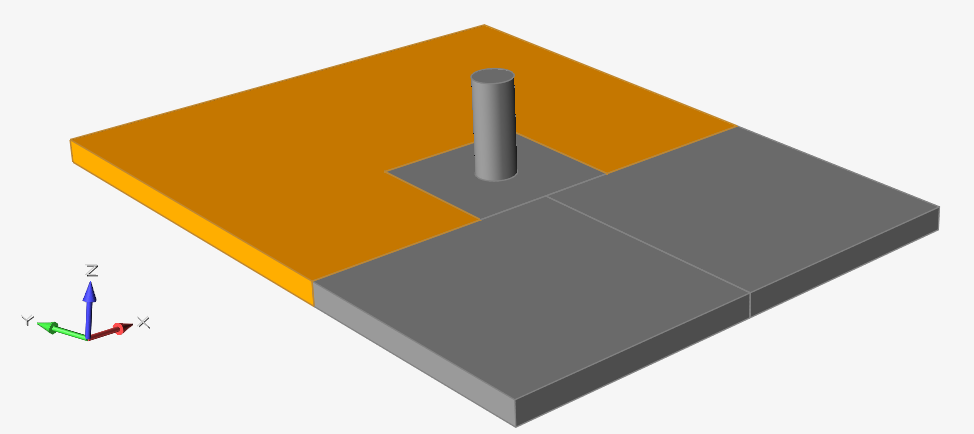

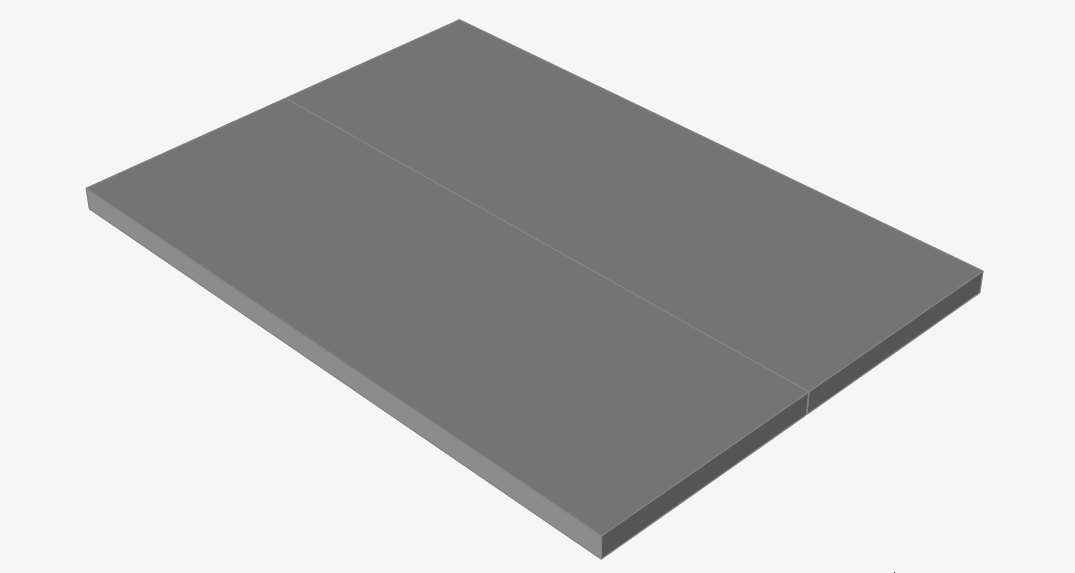

- Import die geometry

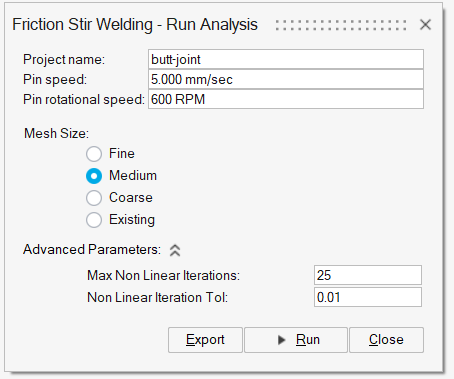

- Set up an analysis for a simple butt joint.

- Launch HyperXtrude solver to run friction stir welding analysis

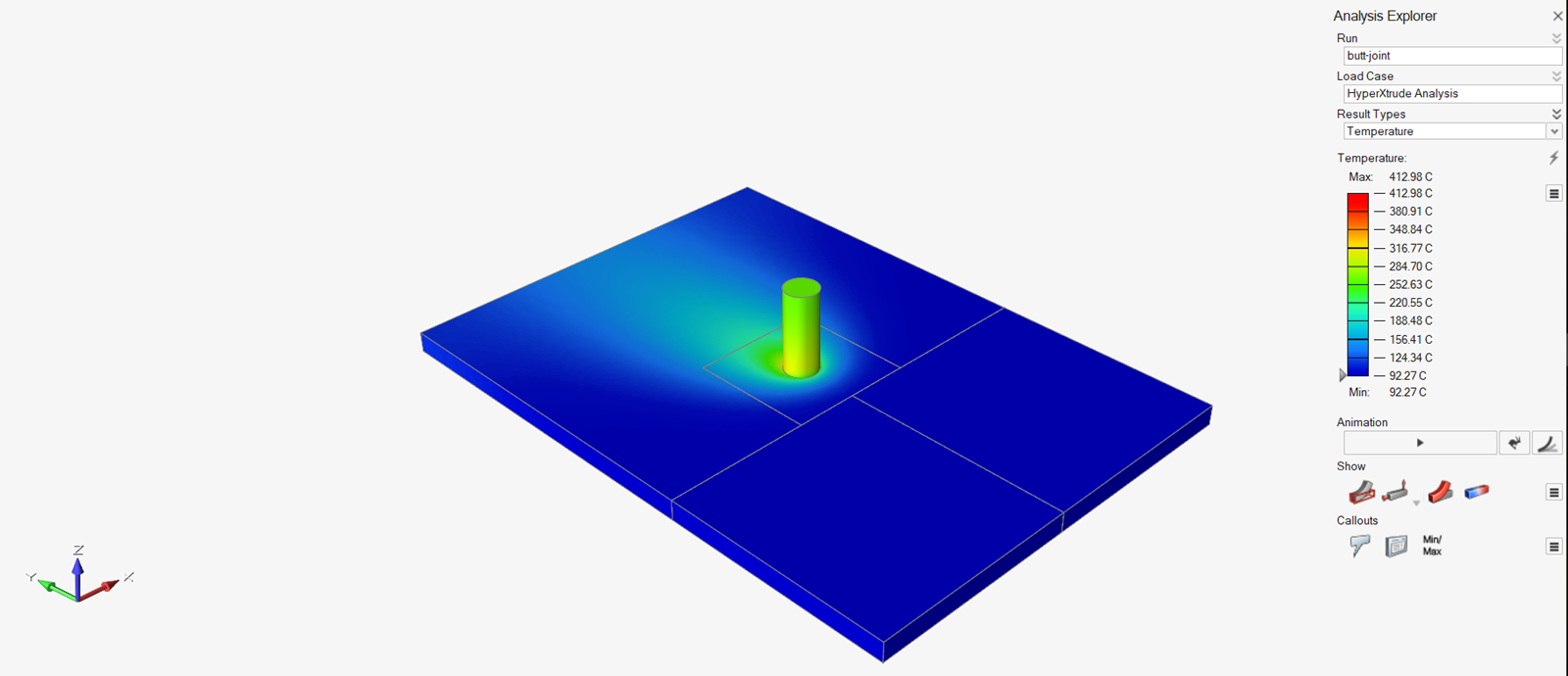

- Post process the results

Open the Tutorial Model

Data files are available in the tutorial_models folder in the installation directory in Program Files\Altair\2022\InspireExtrude2022.2\tutorial_models\fsw\tutorial-1\.

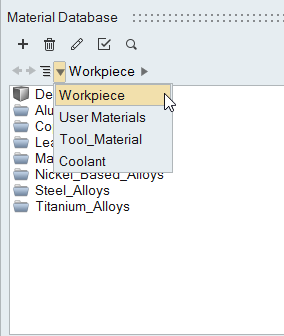

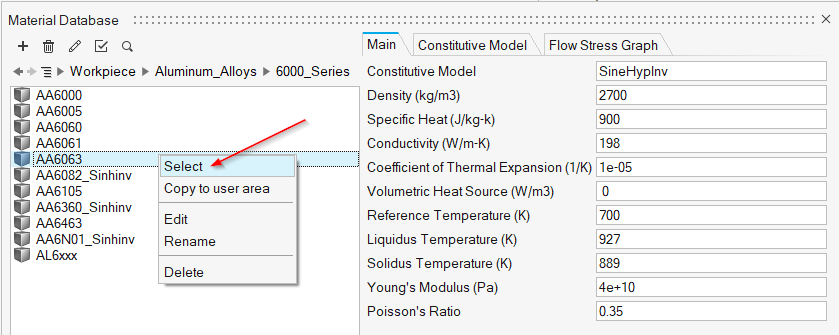

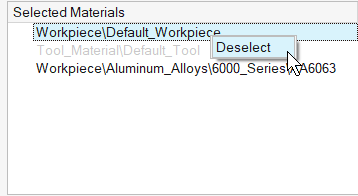

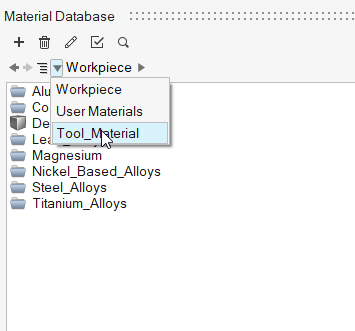

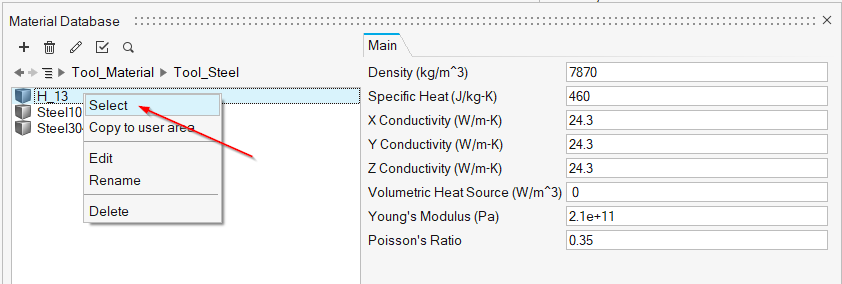

Select Materials

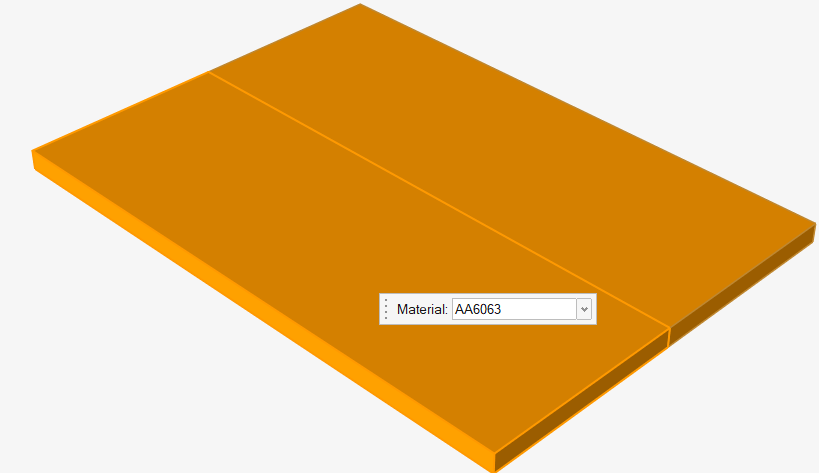

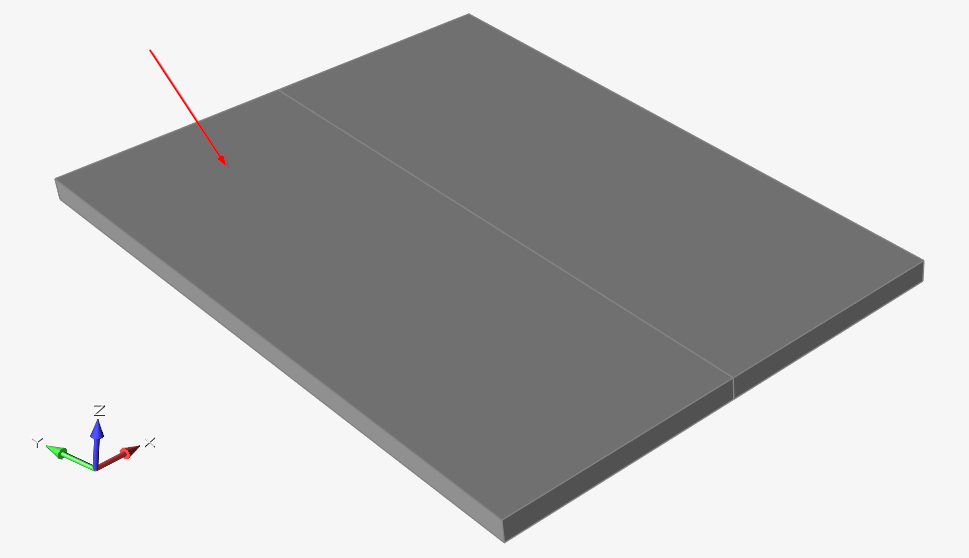

Identify the Plates

Orient the Model

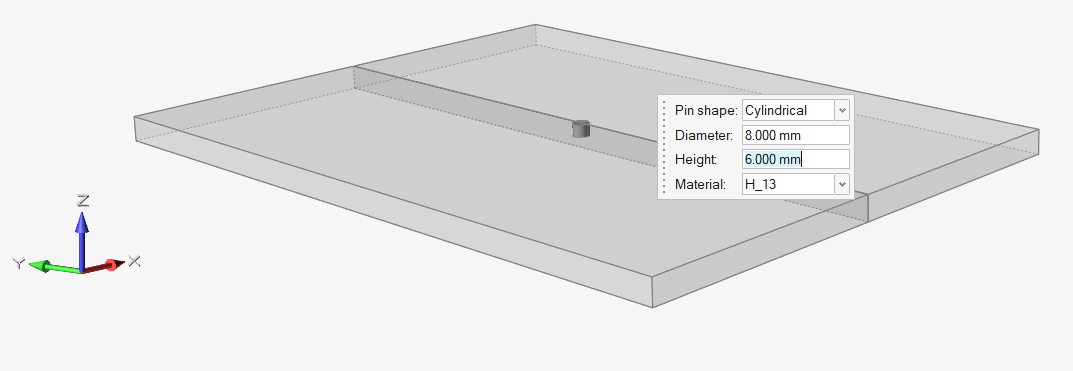

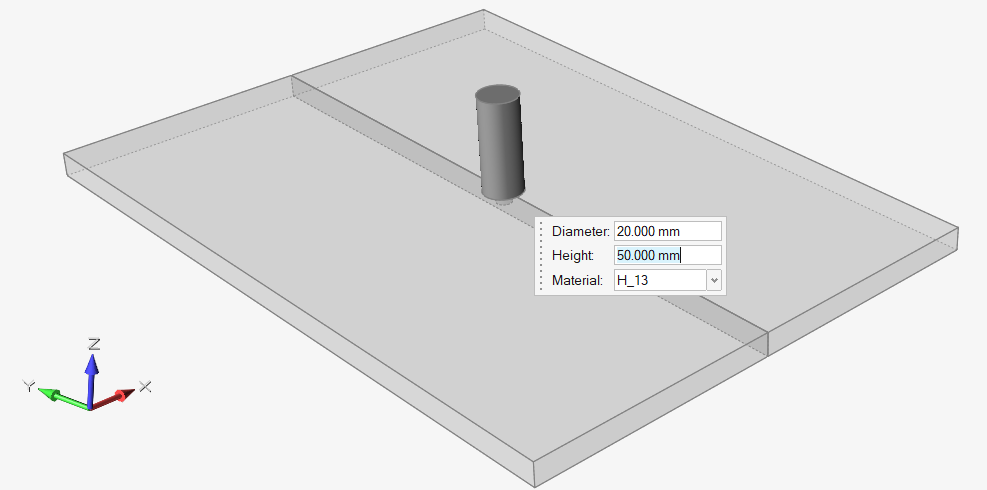

Create the Pin

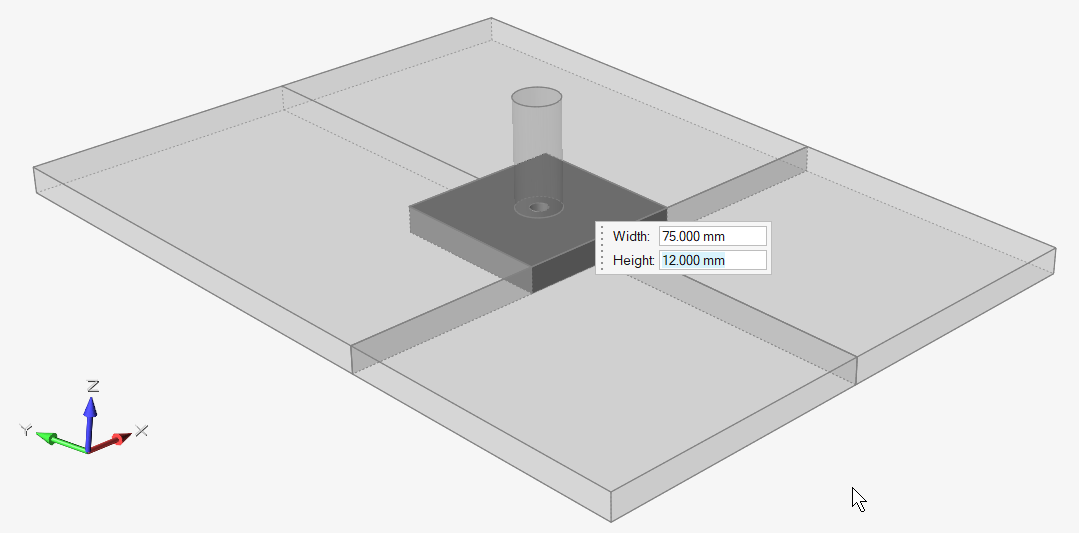

Create the Shoulder

Create HAZ