Tutorial: Analysis with Organized Model

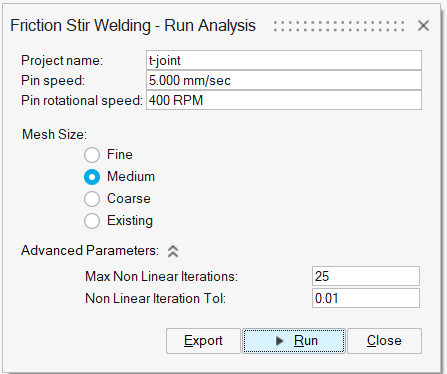

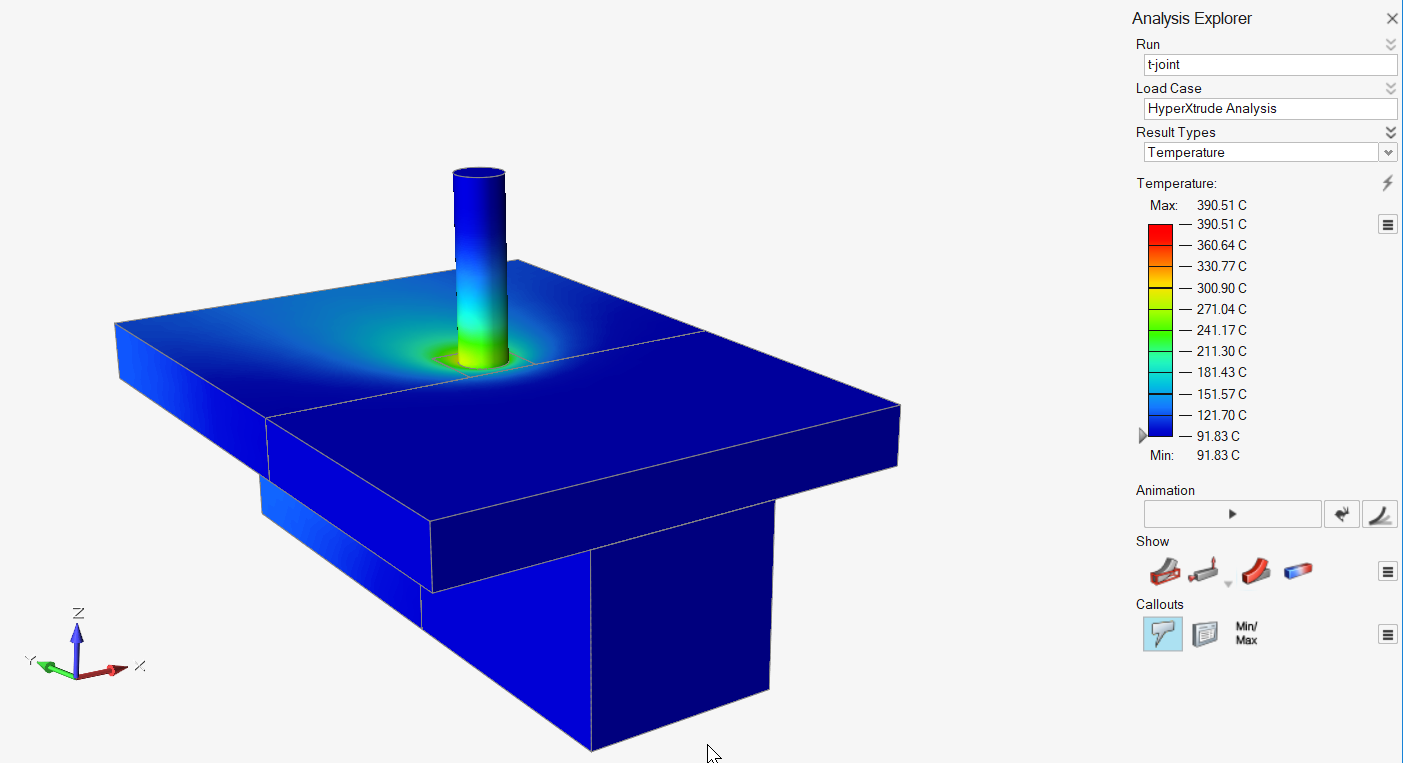

Complete a friction stir welding analysis with an already organized model.

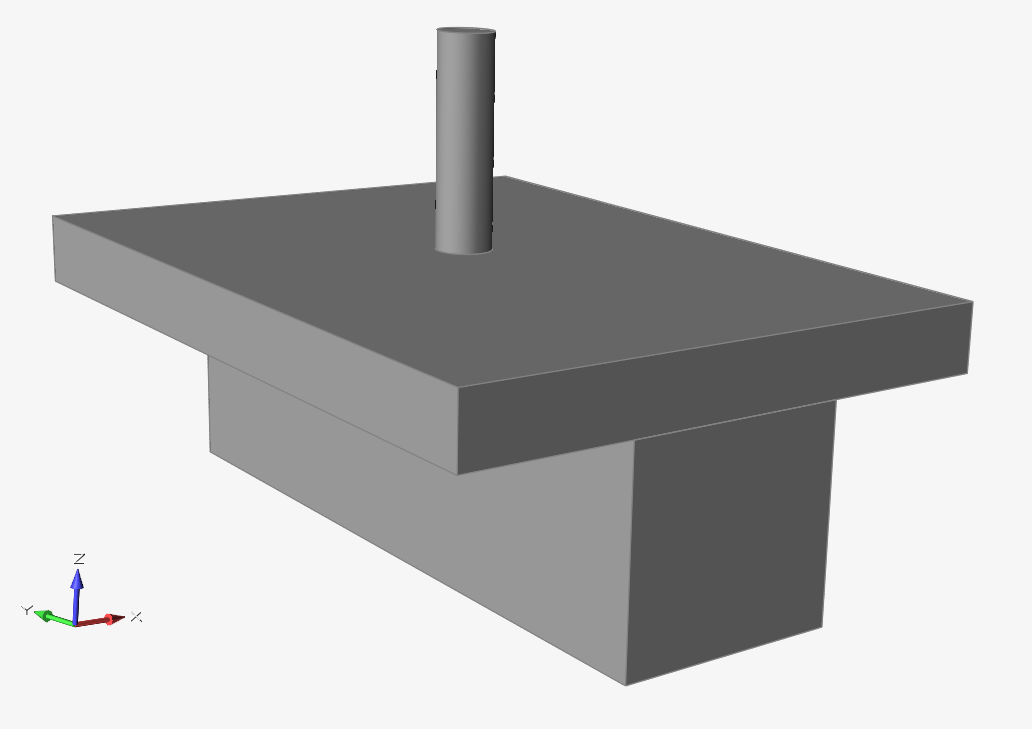

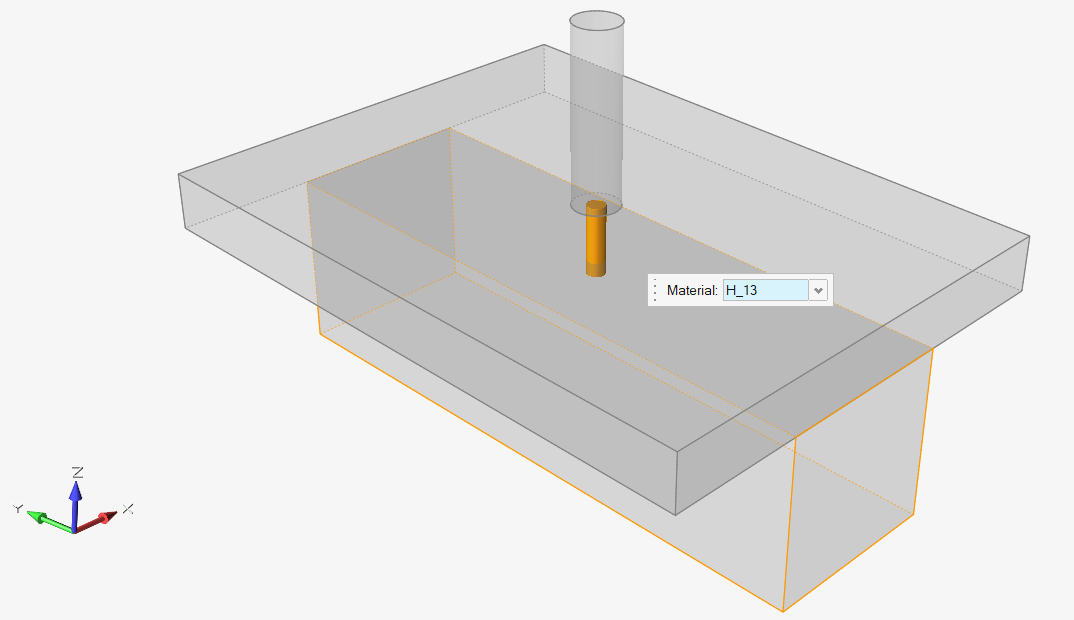

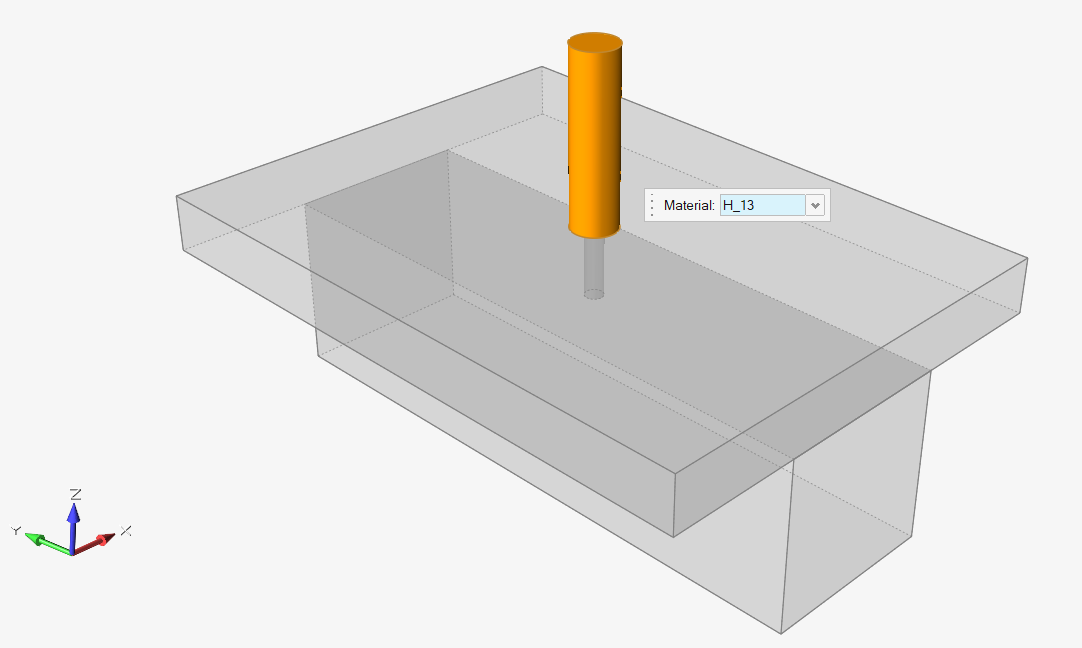

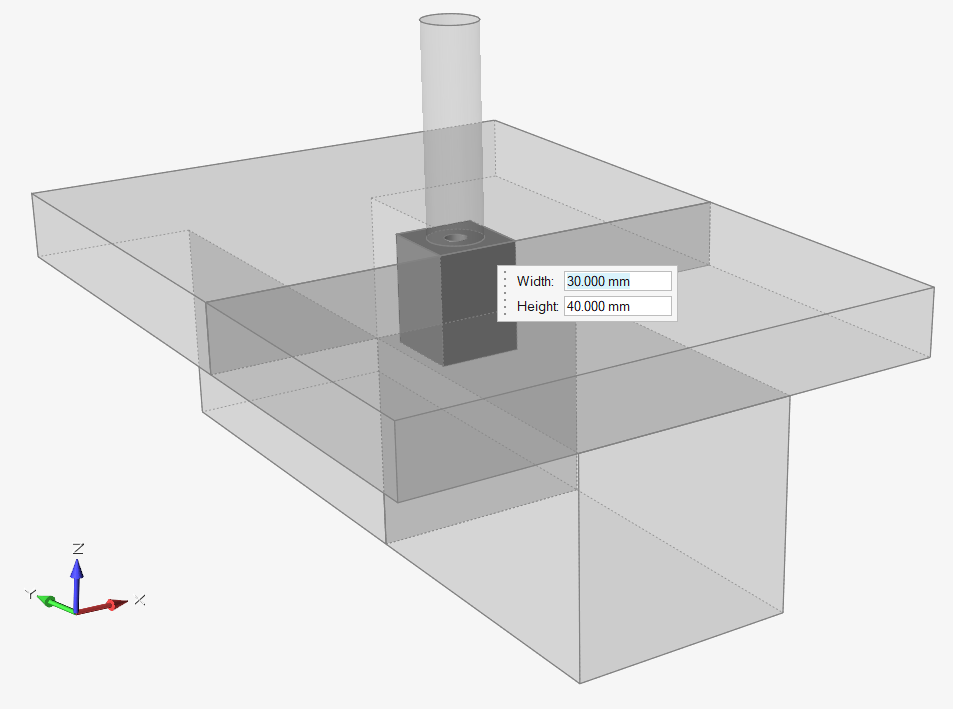

- Import the geometry

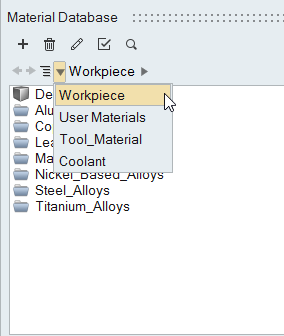

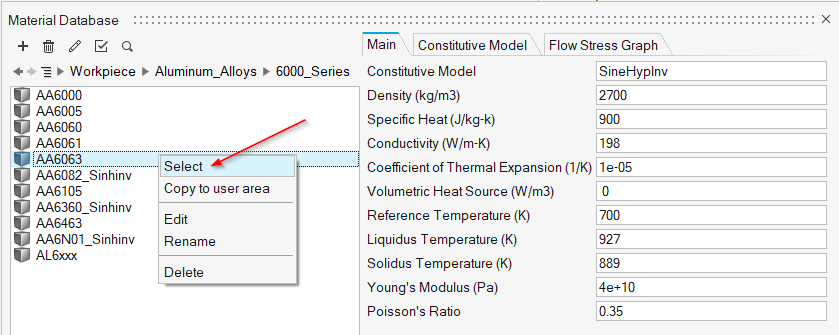

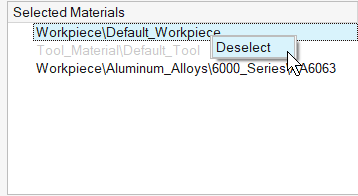

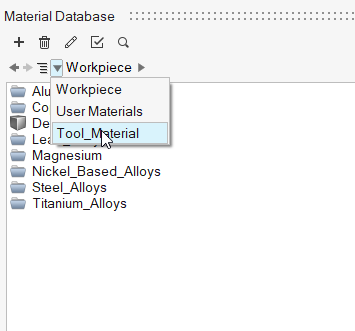

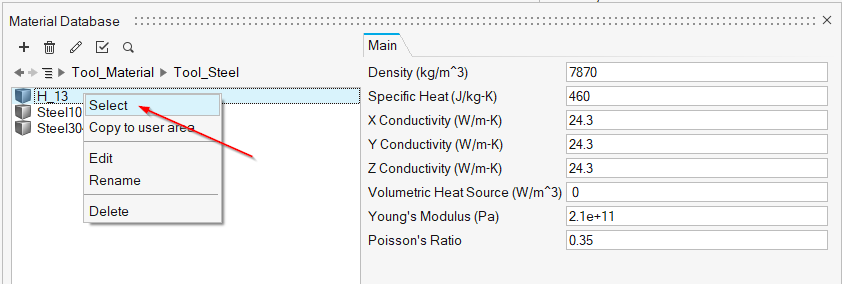

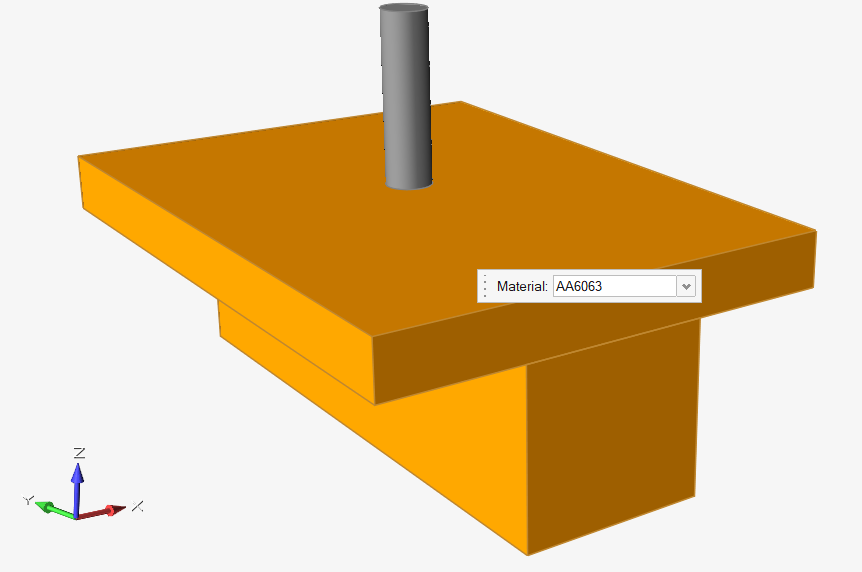

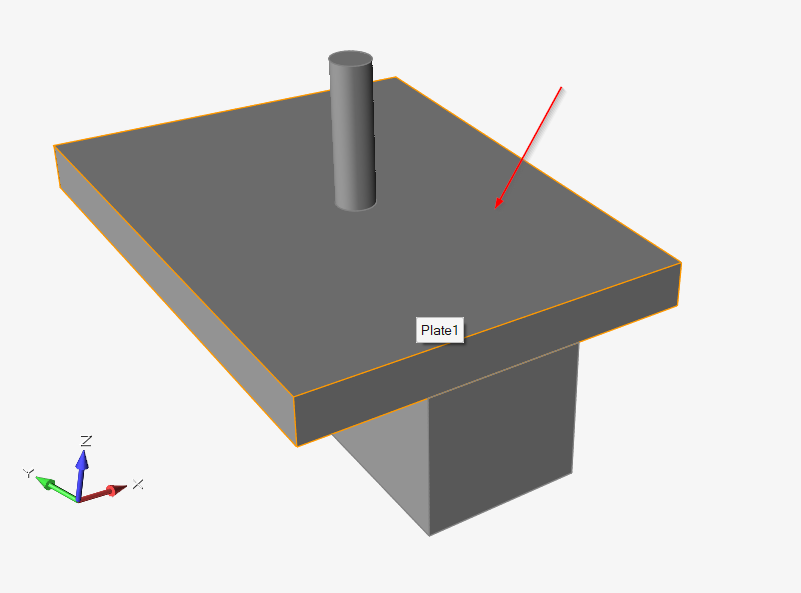

- Identify the parts

- Launch HyperXtrude solver to run Inspire Friction Stir Weldinganalysis

- Post process the results

Open the Tutorial Model

Data files are available in the tutorial_models folder in the installation directory in Program Files\Altair\2022\InspireExtrude2022\tutorial_models\fsw\tutorial-2\.