Package HydraulicsByFluidon.Components.Valves.CheckValves

Package HydraulicsByFluidon.Components.Valves.CheckValvesIcon for standard packages

Package HydraulicsByFluidon.Components.Valves.CheckValves

Package HydraulicsByFluidon.Components.Valves.CheckValves

Standard package icon.

Extends from Modelica.Icons.Package (Icon for standard packages).

| Name | Description |

|---|---|

CheckValvePT1 | |

PilotOperatedCheckValve | |

ShuttleValve | |

ShuttleValveNoFlow | |

ThrottleCheckValvePT1 |

Model HydraulicsByFluidon.Components.Valves.CheckValves.CheckValvePT1

Model HydraulicsByFluidon.Components.Valves.CheckValves.CheckValvePT1

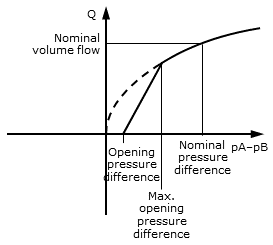

The component CheckValvePT1 is the model of a check valve which blocks the flow in the direction from fluidPortB towards fluidPortA. In the opposite direction, from fluidPortA towards fluidPortB, the valve can be set to represent either a throttle or orifice.

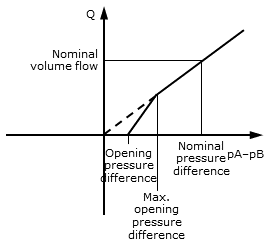

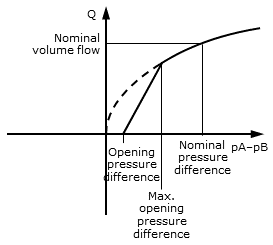

The locking function is thereby represented by a spring. The Opening pressure difference is the pressure difference necessary to overcome the locking spring force. The opening condition is:

fluidPortA.p > fluidPortB.p + Opening pressure difference.

Max. opening pressure difference defines the point where the valve is completely open and the values Nominal volume flow and Nominal pressure difference apply. From Opening pressure difference to Max. opening pressure difference the flow is scaled proportionally.

Throttle

Orifice

The component CheckValvePT1 is not a model of a check valve according to its physical structure. It merely represents the characteristic behavior of a check valve. The dynamic effects which can occur in real valve such as forces due to inertia will be represented by means of the parameter TimeConstant, which is the time constant of an idealized first order mechanical system that can not oscillate.

Extends from HydraulicsByFluidon.Components.Valves.Base.PartialCheckValvePT1.

| Type | Name | Default | Description |

|---|---|---|---|

Pressure | OpeningPressure | 100000 | Opening pressure difference |

Pressure | MaxOpeningPressure | 200000 | Max. opening pressure difference |

VolumeFlowRate | NominalVolumeFlow | 5e-4 | Nominal volume flow |

Pressure | NominalPressureDifference | 500000 | Nominal pressure difference |

TResistorTypes | resistorType | HydraulicsByFluidon.Types.TResistorTypes.Orifice | Type of the resistor |

Density | ReferenceDensity | 860 | Reference density for volume flow and pressure difference |

Time | TimeConstant | 0.001 | Time constant of the first order delay |

Volume | deadVolume | 1e-6 | Dead volume at ports |

Boolean | forwardFluidProperties | true | Forward fluid properties between ports |

| Type | Name | Description |

|---|---|---|

FluidPort | fluidPortA | Hydraulic port A |

FluidPort | fluidPortB | Hydraulic port B |

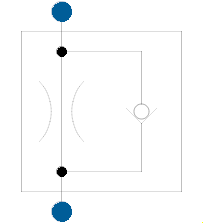

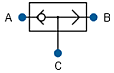

Model HydraulicsByFluidon.Components.Valves.CheckValves.PilotOperatedCheckValve

Model HydraulicsByFluidon.Components.Valves.CheckValves.PilotOperatedCheckValve

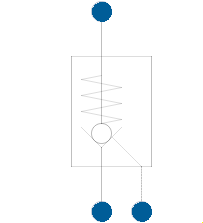

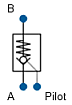

The component PilotOperatedCheckValve allows free flow through the check valve from A to B and blocks the reverse flow until the pilot pressure directly proportional to the load in the pilot line, so that the pilot piston can push the check poppet off its seat. The component PilotOperatedCheckValve is the model of a check valve which blocks the flow in the direction from fluidPortB towards fluidPortA. In the opposite direction, from fluidPortA towards fluidPortB, the valve can be set to represent either a throttle or orifice. In addition to pressure at fluidPortA the valve can be opened by pressure at fluidPortPilot.

The locking function is thereby represented by a spring. The Opening pressure difference is the pressure difference necessary to overcome the locking spring force. The opening condition is:

fluidPortA.p + Pilot ratio * Pilot pressure > fluidPortB.p + Opening pressure difference.

with Pilot ratio = Pilot piston area / Check valve seat area

Max. opening pressure difference defines the point where the valve is completely open and the values Nominal volume flow and Nominal pressure difference apply. From Opening pressure difference to Max. opening pressure difference the flow is scaled proportionally.

Throttle

Orifice

The component PilotOperatedCheckValve is not a model of a check valve according to its physical structure. It merely represents the characteristic behavior of a check valve. The dynamic effects which can occur in real valve such as forces due to inertia will be represented by means of the parameter TimeConstant, which is the time constant of an idealized first order mechanical system that can not oscillate.

Extends from HydraulicsByFluidon.Components.Valves.Base.PartialCheckValvePT1.

| Type | Name | Default | Description |

|---|---|---|---|

DimensionlessRatio | pilotRatio | 3 | Pilot ratio |

Pressure | OpeningPressure | 100000 | Opening pressure difference |

Pressure | MaxOpeningPressure | 200000 | Max. opening pressure difference |

VolumeFlowRate | NominalVolumeFlow | 5e-4 | Nominal volume flow |

Pressure | NominalPressureDifference | 500000 | Nominal pressure difference |

TResistorTypes | resistorType | HydraulicsByFluidon.Types.TResistorTypes.Orifice | Type of the resistor |

Density | ReferenceDensity | 860 | Reference density for volume flow and pressure difference |

Time | TimeConstant | 0.001 | Time constant of the first order delay |

Volume | deadVolume | 1e-6 | Dead volume at ports |

Boolean | forwardFluidProperties | true | Forward fluid properties between ports |

| Type | Name | Description |

|---|---|---|

FluidPort | fluidPortA | Hydraulic port A |

FluidPort | fluidPortB | Hydraulic port B |

FluidPort | fluidPortPilot | Hydraulic port pilot |

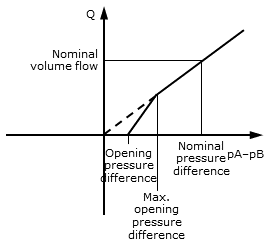

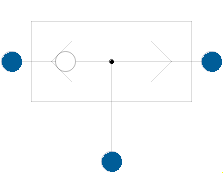

Model HydraulicsByFluidon.Components.Valves.CheckValves.ThrottleCheckValvePT1

Model HydraulicsByFluidon.Components.Valves.CheckValves.ThrottleCheckValvePT1

The component ThrottleCheckValvePT1 is a model that combines a throttle and a check valve. If pressure p2 > p1 the flow passes the throttle only whereas if the pressure p1 > p2 the flow will be distributed over throttle and check valve according to the respective resistances.

The opening condition is:

fluidPortA.p > fluidPortB.p + Opening pressure difference.

Max. opening pressure difference defines the point where the check valve is completely open and the values Nominal volume flow and Nominal pressure difference apply. From Opening pressure difference to Max. opening pressure difference the flow is scaled proportionally.

Extends from HydraulicsByFluidon.Components.Base.HydTwoPortVerticalExt.

| Type | Name | Default | Description |

|---|---|---|---|

VolumeFlowRate | NominalVolumeFlowThrottle | 5e-4 | Nominal volume flow |

Pressure | NominalPressureDifferenceThrottle | 500000 | Nominal pressure difference |

Pressure | OpeningPressureCV | 100000 | Opening pressure difference |

Pressure | MaxOpeningPressureCV | 200000 | Opening pressure difference |

VolumeFlowRate | NominalVolumeFlowCV | 5e-4 | Nominal volume flow |

Pressure | NominalPressureDifferenceCV | 500000 | Nominal pressure difference |

TResistorTypes | resistorTypeCV | HydraulicsByFluidon.Types.TResistorTypes.Orifice | Type of the resistor |

Density | ReferenceDensity | 860 | Reference density for volume flow and pressure difference |

Volume | deadVolume | 1e-6 | Dead volume at ports |

Boolean | forwardFluidProperties | true | Forward fluid properties between ports |

| Type | Name | Description |

|---|---|---|

FluidPort | fluidPortA | Hydraulic port A |

FluidPort | fluidPortB | Hydraulic port B |

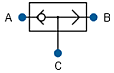

Model HydraulicsByFluidon.Components.Valves.CheckValves.ShuttleValve

Model HydraulicsByFluidon.Components.Valves.CheckValves.ShuttleValve

The component ShuttleValve is the model of a changeover valve with Dead volume at each port. It connects port C (the middle port) with the port that has the highest pressure. The flow characteristic is represented by an orifice.

SwitchingThreshold defines deadband to avoid chattering. The shuttle valve switches from A to B when

pressure A > (pressure B + SwitchingThreshold)

and switches from B to A when

pressure A < (pressure B - SwitchingThreshold)

A typical application of this valve is in a load sensing system to determine the highest load pressure.

Note: Due to small volumes between the ShuttleValve and connected components and switching action, a very high numerical stiffness may occur, resulting in small step sizes.

| Type | Name | Default | Description |

|---|---|---|---|

VolumeFlowRate | NominalVolumeFlow | 5e-4 | Nominal volume flow |

Pressure | NominalPressureDifference | 500000 | Nominal pressure difference |

Density | ReferenceDensity | 860 | Reference density for volume flow and pressure difference |

Pressure | SwitchingThreshold | 100 | Pressure threshold to switch between ports |

Volume | deadVolume | 1e-6 | Dead volume at ports |

Boolean | forwardFluidProperties | true | Forward fluid properties between ports |

| Type | Name | Description |

|---|---|---|

FluidPort | fluidPortA | Hydraulic port A |

FluidPort | fluidPortB | Hydraulic port B |

FluidPort | fluidPortC | Hydraulic port C |

Model HydraulicsByFluidon.Components.Valves.CheckValves.ShuttleValveNoFlow

Model HydraulicsByFluidon.Components.Valves.CheckValves.ShuttleValveNoFlow

The component ShuttleValveNoFlow is the model of a changeover valve that has no flow through the valve, but only transmits the pressure. It connects port C (the middle port) with the port that has the highest pressure.

A typical application of this valve is in a load sensing system to determine the highest load pressure.

If you need a shuttle valve that also has a flow characteristic, you can use the component ShuttleValve.

| Type | Name | Default | Description |

|---|---|---|---|

Volume | deadVolume | 1e-6 | Dead volume at ports |

Boolean | forwardFluidProperties | true | Forward fluid properties between ports |

| Type | Name | Description |

|---|---|---|

FluidPort | fluidPortA | Hydraulic port A |

FluidPort | fluidPortB | Hydraulic port B |

FluidPort | fluidPortC | Hydraulic port C |