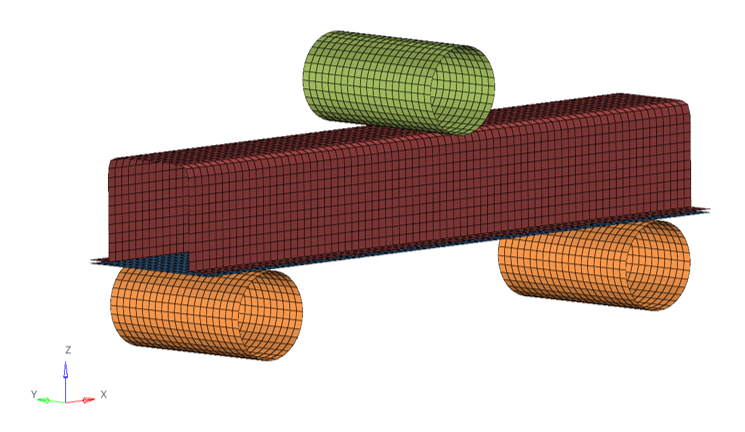

RD-HWX-T: 1060 Three Point Bending Model Setup

This tutorial demonstrates how to set up a 3-point bending model consisting of a head profile and a closing plate.

Figure 1.

- Step 1: Import Solverdeck

- Step 2: Check /BEGIN card

- Step 3: Define material

- Step 4: Assign material

- Step 5: Define property

- Step 6: Assign property

- Step 7: Create solid spotweld

- Step 8: Define failure /FAIL/CONNECT

- Step 9: Define rigid body

- Step 10: Create boundary condition

- Step 11: Create imposed velocity

- Step 12: Set contact

- Step 13: Define output (time history / anim)

- Step 14: Create Engine setup and export the model

- Step 15: Run the model and check the results in HyperView and HyperGraph

Model Description

- Material creation (with strain curve creation) and assignment:

- Elasto-plastic material /MAT/LAW36 (plastic):

- [Rho_I] Initial density = 7.85e-09 (ton/mm3)

- [nu] Poisson’s ratio = 0.29

- [E] Young’s modulus = 210000 (Mpa)

- Elasto-plastic material /MAT/LAW36 (plastic):

- UNITS: Length (mm), Time (s), Mass (t)

- Simulation time: [0 – 7.01E-02]

- Boundary Conditions: The supports are all fixed. An imposed velocity of 1000.0 mm/s is applied on the impactor.

- Model size: 370mm x 46.5mm x 159mm

Prerequisites

To run this simulation, you will need access to a licensed version of Radioss. You will need an internet connection to watch the video tutorials and download the files.