ACU-T: 2300 Atmospheric Boundary Layer Problem – Flow Over Building

Prerequisites

Prior to starting this tutorial, you should have already run through the introductory HyperWorks tutorial, ACU-T: 1000 HyperWorks UI Introduction. To run this simulation, you will need access to a licensed version of HyperMesh and AcuSolve.

Since the HyperMesh database (.hm file) contains meshed geometry, this tutorial does not include steps related to geometry import and mesh generation.

Problem Description

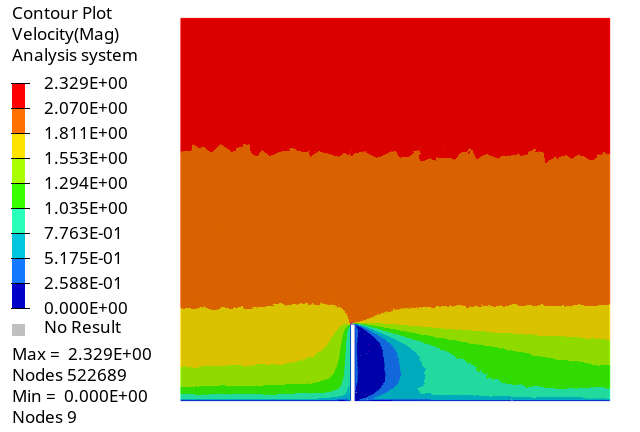

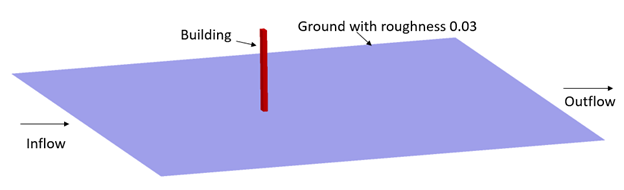

The problem to be addressed in this tutorial is shown schematically in Figure 1. As an example, this problem shows the capability of Atmospheric Boundary Layer modelling in AcuSolve.

Figure 1.

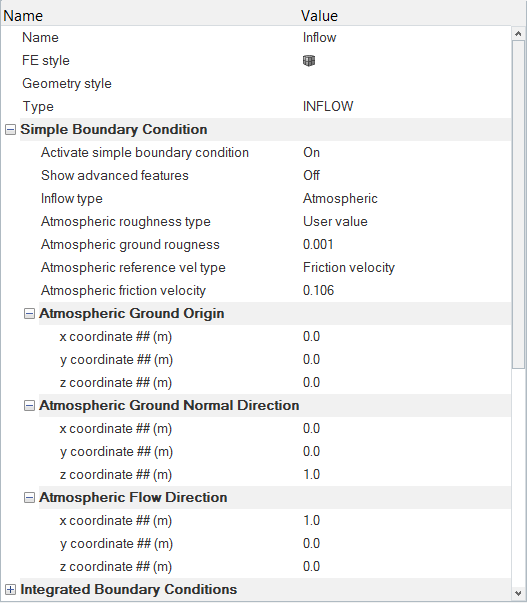

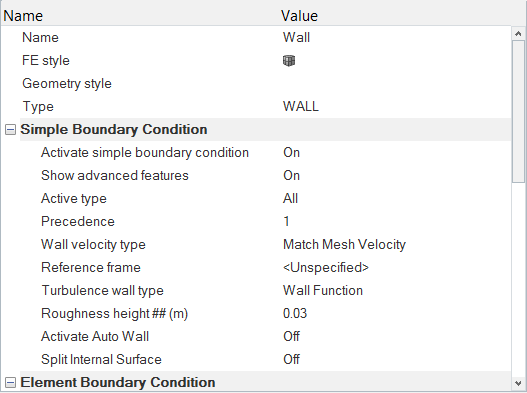

In this tutorial, you will simulate the air flow over a building with a ground roughness of 0.03. In this case, User Defined Atmospheric Roughness Type is considered.

Open the HyperMesh Model Database

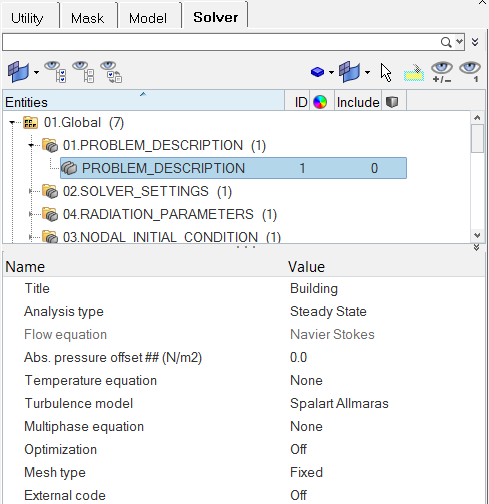

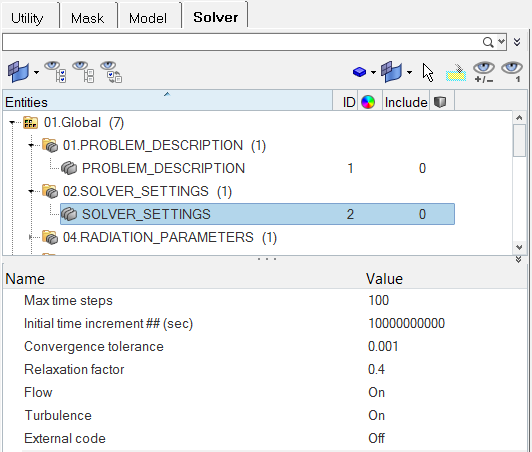

Set the General Simulation Parameters

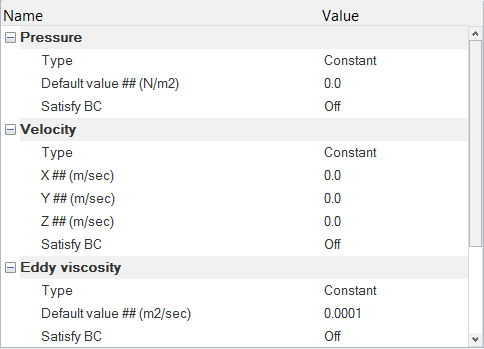

Set Up Boundary Conditions and Material Model Parameters

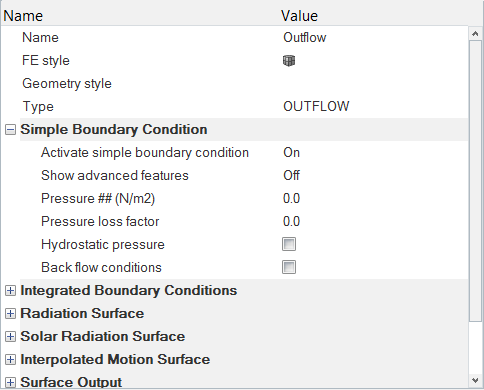

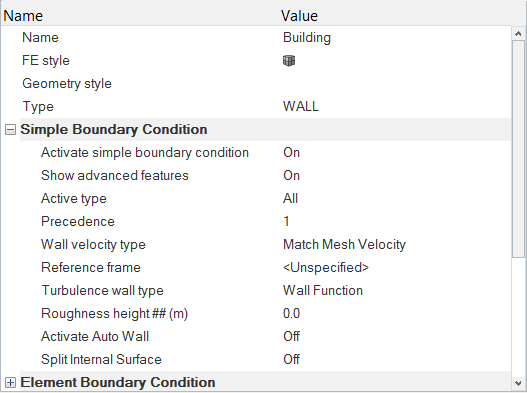

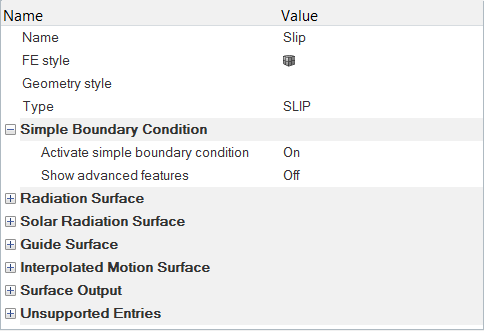

In this step, you will define the Boundary Conditions (BCs) for the problem and assign material properties to the fluid volume.

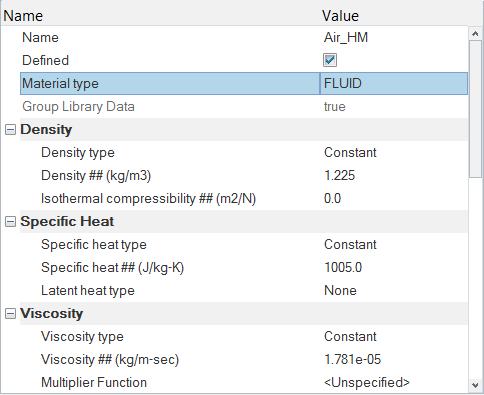

Set Up Material Model Parameters

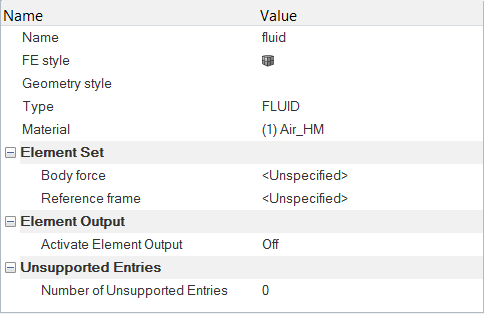

Set Up Fluid Volume Material

Set Up Boundary Conditions

Set Up Nodal Initial Conditions

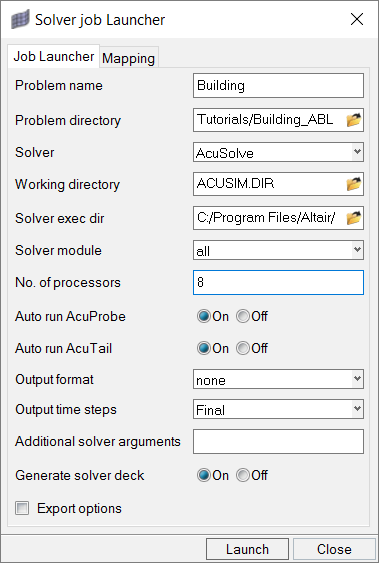

Compute the Solution

In this step, you will launch AcuSolve directly from HyperMesh and compute the solution.

Run AcuSolve

Post-Process the Results with HyperWorks HV

Start HyperView from the Windows Start menu by clicking .

Load Model and Results

- Once the HyperWorks HV window is loaded, click .

-

In the Load model and results panel, click

next

to Load model.

next

to Load model.

- In the Load Model File dialog, navigate to your working directory and select the AcuSolve .Log file for the solution run that you want to post-process. In this example, the file to be selected is Building.1.Log.

- Click Open.

- Click Apply in the panel area to load the model and results.

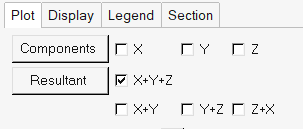

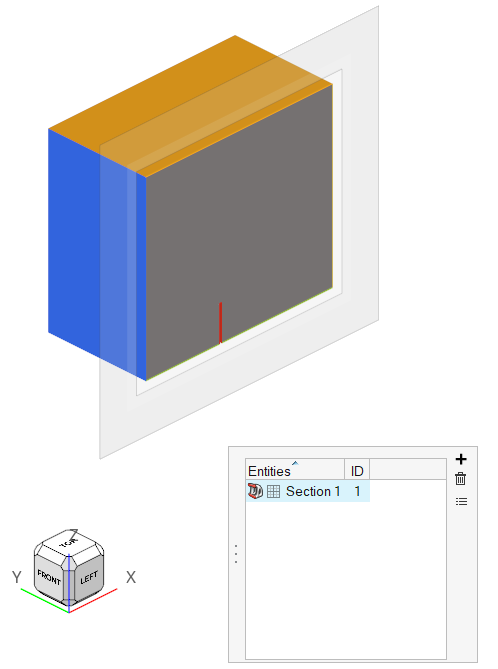

Coordinate the Surface for Showing Velocity Magnitude on the Y Plane

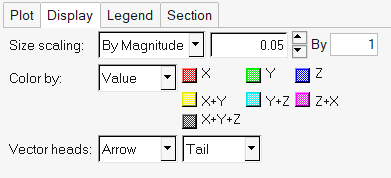

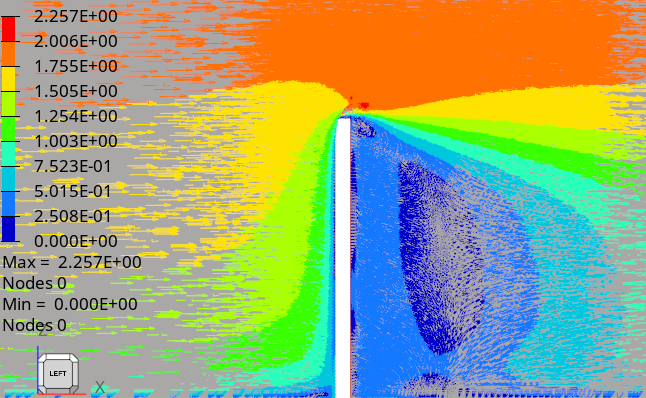

Coordinate the Surface for Showing Velocity Vectors on the Y Plane

Summary

In this tutorial, you worked through a basic workflow to set up a CFD model, carry out a CFD simulation, then post-process the results using HyperWorks products, namely AcuSolve, HyperMesh and HyperWorks HV. You started by importing the model in HyperMesh. Then, you defined the simulation parameters and launched AcuSolve directly from within HyperMesh. Upon completion of solution by AcuSolve, you used HyperWorks HV to post-process the results and create contour and vector plots.

in the

in the