Seam Realization

Overview of the seam connector realization process and methods.

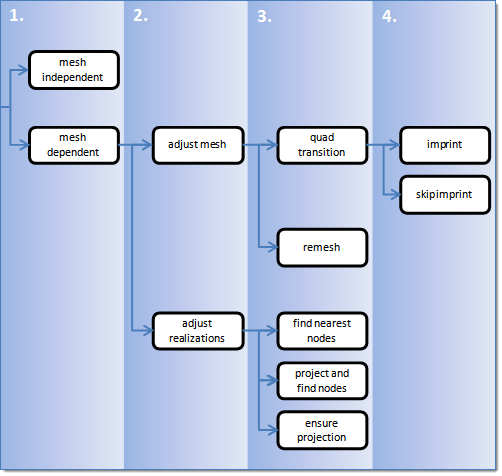

Seam Realization Process

Overview of the seam realization process.

- Select the realization type.

- mesh independent

- Use for realizations which do not need a node connection and the connection is primarily defined via a solver-specific card, such as LLINKs for PAM-CRASH.

- mesh dependent

- Use for all other cases.

- If mesh dependent is selected, you must decide

whether or not to adjust the mesh or the realization.

- Adjust mesh

- Projection is done in a perpendicular way, and the mesh has to be adapted to the projection points.

- Adjust realization

- The mesh will not be modified, at the expense of non-normal or incomplete realizations. Many realization types are defined with head elements attached to body elements. In the case of these realization types, the head elements realize the connection without modifying the mesh, and the body elements are created in a normal direction.

- Choose how the adjustments should take place.

- Adjust mesh

- Sub-options include: quad transition and remesh.

- Adjust realizations

- Sub-options include: find nearest nodes, project and find nodes, and ensure projection.

- Choose whether or not the imprint should be skipped for quad transition.

Figure 1. Seam Realization Process

Seam Realization Methods

Overview of the different options for seam realization methods.

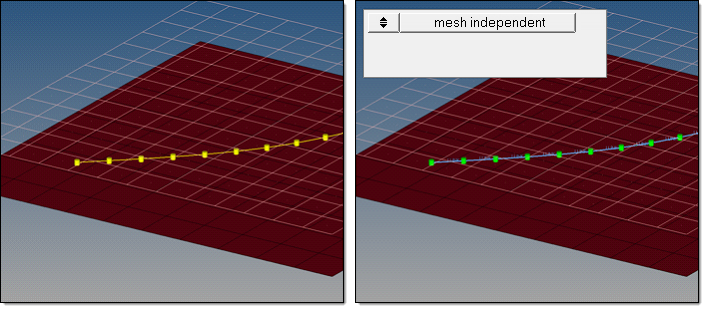

Mesh Independent

Figure 2. Mesh Independent

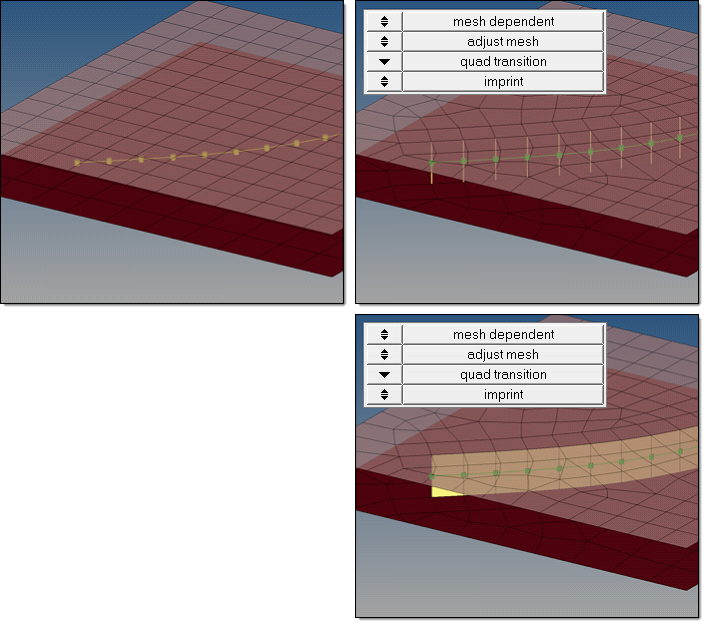

Mesh Dependent – Adjust Mesh – Quad Transition - Imprint

- Quad Transition

- The quad transition option creates perfectly shaped quad elements around the projection line. The quad size is determined by the average mesh size. From one projection point to the next, exactly one pair of elements is created. You can also use this option to create seams from quad elements, and realize the connections to the links through perfectly modeled t-edges.

- Imprint

- When creating mesh-dependent realizations with quad transitions, the quad transition meshes can overlap and disturb each other if more than one set of connectors is created too close to each other. The imprint option reconciles such transitions with each other and modifies the underlying mesh to match the results to create a final result that is seamless and properly meshed.

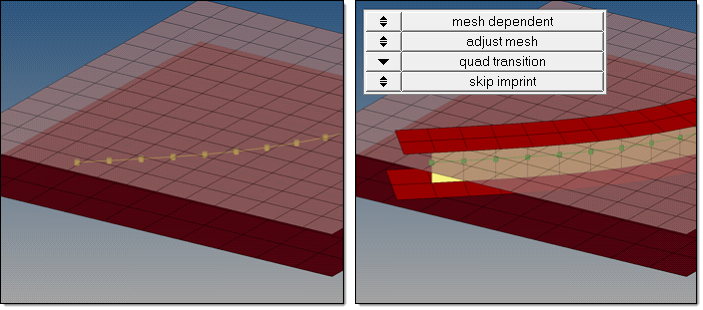

Mesh Dependent – Adjust Mesh – Quad Transition – Skip Imprint

- Quad Transition

- The quad transition option creates perfectly shaped quad elements around the projection line. The quad size is determined by the average mesh size. From one projection point to the next, exactly one pair of elements is created. You can also use this option to create seams from quad elements, and realize the connections to the links through perfectly modeled t-edges.

- Skip Imprint

- The skip imprint option prevents the last step of quad transition from being performed. The component ^conn_imprint is created instead, which contains the element pattern. These elements can be modified and manually imprinted later using the Connector Imprint panel.

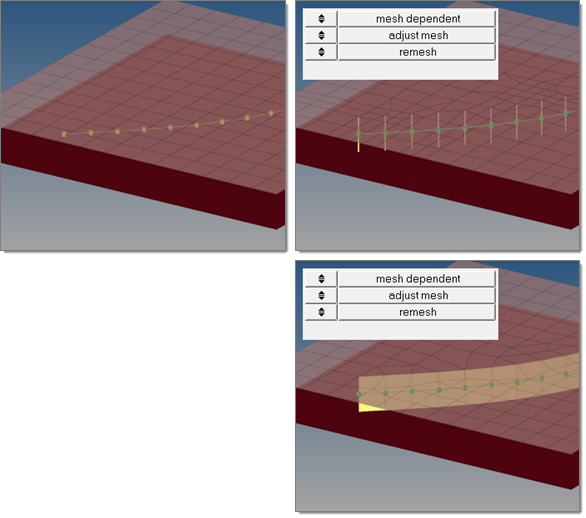

Mesh Dependent – Adjust Mesh – Remesh

Figure 5. Remesh

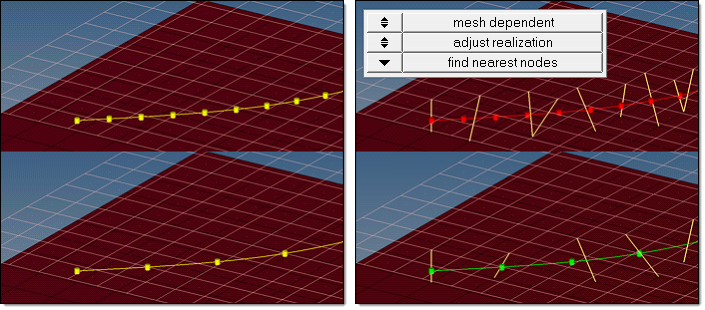

Mesh Dependent – Adjust Realization – Find Nearest Nodes

Figure 6. Find Nearest Nodes

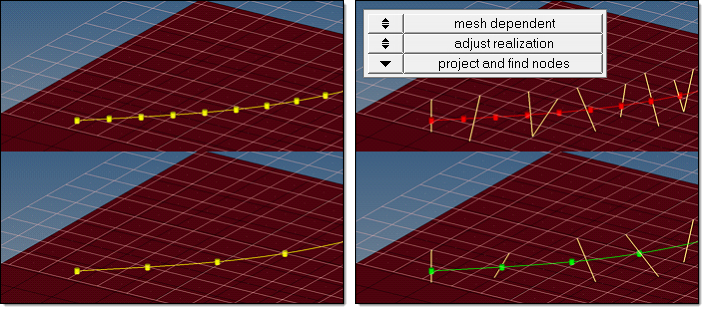

Mesh Dependent – Adjust Realization – Project and Find Nodes

Figure 7. Project and Find Nodes

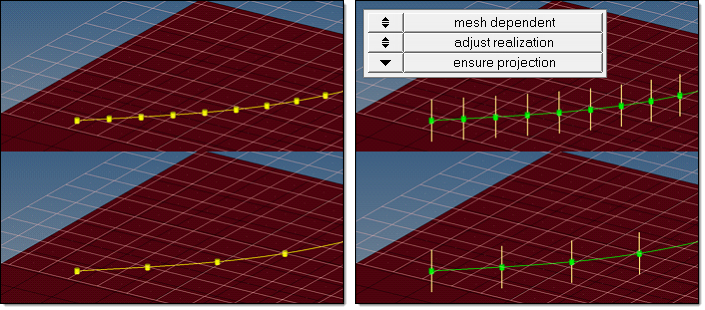

Mesh Dependent – Adjust Realization – Ensure Projection

When using the ensure projection option, the minimum condition for the realization is a possible normal projection. The realization will be performed in the direction from one projection point to the next. If the projection point is coincident with a shell node they will be equivalenced.

Ensure projection can lead to incompletely defined connections from a solver perspective unless the connector positions are not aligned to the mesh. The advantage of this projection method is the exact determination of the projection points.

Figure 8. Ensure Projection

Stitch Connector

| Option | Description |

|---|---|

| Select a Parent Link | Takes the lead link information from the selected item. In most situations, this can be left blank and it will be determined internally by the shape of the weld. For example, a T joint or a Lap joint. |

| After Stitch | Realization options for how the mesh is tied together. |

| Keep Node IDs | Describes how to maintain the best possible numbering of the end nodes when tying the two plates together. |

| Imprint Project Options | Specifies the shortest projection or tangency to keep the shape of the plate if there is a shorter projection. |