/DCOMP

Optimization Keyword Defines manufacturing constraints for composite sizing optimization.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /DCOMP/dcomp_ID | |||||||||

| title | |||||||||

| grpart_ID | |||||||||

| CTYP=1: | |||||||||

| CTYP | LTMIN | LTMAX | grsh3n_ID | grshel_ID | LTEXC | ||||

| CTYP=2: | |||||||||

| CTYP | PTANGLE | PTMIN | PTMAX | grsh3n_ID | grshel_ID | PTEXC | |||

| CTYP=3: | |||||||||

| CTYP | PPANGLE | PPMIN | PPMAX | grsh3n_ID | grshel_ID | PPEXC | |||

| CTYP=4: | |||||||||

| CTYP | BANGLE1 | BANGLE2 | |||||||

| CTYP=5: | |||||||||

| CTYP | CANGLE | CTHICK | |||||||

| CTYP=6: | |||||||||

| CTYP | PDANGLE | PDTYP | PDMAX | grsh3n_ID | grshel_ID | PDEXC | |||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| dcomp_ID | Manufacturing constraints for composite sizing

optimization identifier (Integer > 0) |

|

| title | Title (Character, maximum 100 characters) |

|

| grpart_ID | Part

group identifier defining the design

space. (Integer > 0) |

|

| COMP | Composite manufacturing constraints applied are indicated. Indicates that information about manufacturing constraints is to follow. The value of COMP is equal to the total number of composite manufacturing definitions that follow. | |

| CTYP | Composite manufacturing type definition flag.

(Integer) |

|

| LTMIN | Minimum laminate thickness for the laminate

thickness constraint

(CTYP=1). (Real or blank) |

|

| LTMAX | Maximum laminate thickness for the laminate

thickness constraint

(CTYP=1). (Real or blank) |

|

| grsh3n_ID | 3-node shell group identifier (Integer > 0) |

|

| grshel_ID | 4-node shell group identifier (Integer > 0) |

|

| LTEXC | Indicates that certain plies are excluded from

the laminate thickness constraint

(CTYP=1).

Supported options are:

(Integer) |

|

| PTANGLE | Ply

orientation in degrees to which the ply thickness

constraint

(CTYP=2) is

applied. (Real) |

|

| PTMIN | Minimum thickness for the ply thickness

constraint

(CTYP=2). (Real or blank) |

|

| PTMAX | Maximum thickness for the ply thickness

constraint

(CTYP=2). (Real or blank) |

|

| PTEXC | Indicates that certain plies are excluded from

the ply thickness constraint

(CTYP=2).

Supported options are:

(Integer) |

|

| PPANGLE | Ply

orientation in degrees to which the ply thickness

percentage constraint is applied

(CTYP=3). (Real) |

|

| PPMIN | Minimum percentage thickness for the ply

thickness percentage constraint

(CTYP=3). (Real or blank) |

|

| PPMAX | Maximum percentage thickness for the ply

thickness percentage constraint

(CTYP=3). (Real or blank) |

|

| PPEXC | Indicates that certain plies are excluded from

the ply thickness percentage constraint

(CTYP=3).

Supported options are:

(Integer) |

|

| BANGLE1 | First ply orientation in degrees to which the

balance constraint is applied

(CTYP=4). (Real) |

|

| BANGLE2 | Second ply orientation in degrees to which the

balance constraint is applied

(CTYP=4). (Real) |

|

| CANGLE | Ply

orientation in degrees to which the constant

thickness constraint is applied

(CTYP=5). (Real) |

|

| CTHICK | Constant ply thickness for the constant thickness

constraint

(CTYP=5). (Real) |

|

| PDANGLE | Ply

orientation in degrees to which the ply drop-off

constraint is applied

(CTYP=6). (Real) |

|

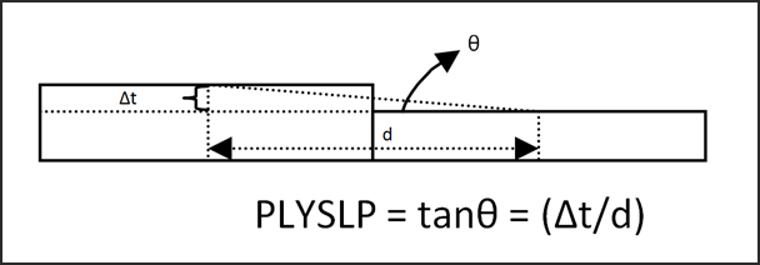

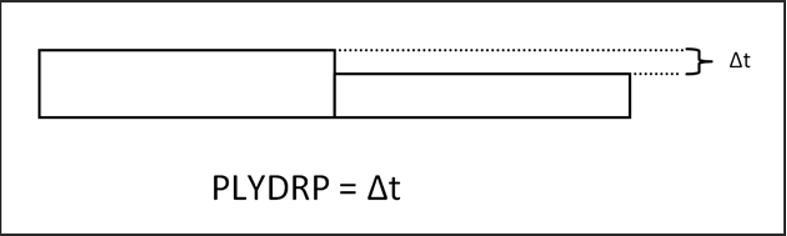

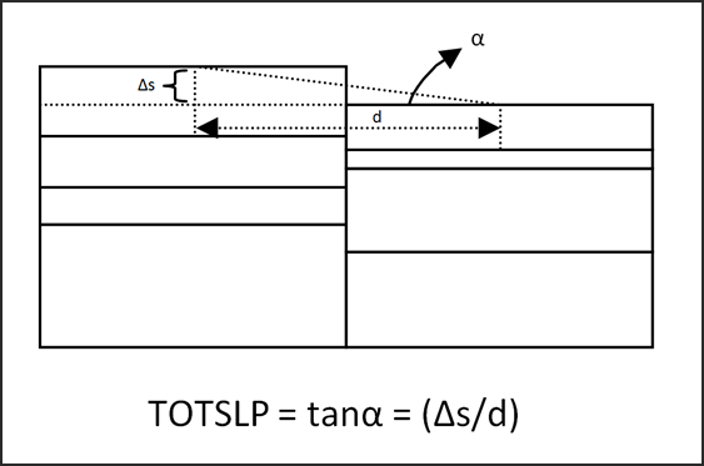

| PDTYP | Drop-off constraint types. 1

(Integer) |

|

| PDMAX | Maximum allowed drop-off for the ply drop-off

constraint

(CTYP=6). (Real) |

|

| PDEXC | Indicates that certain plies are excluded from

the ply drop-off constraint

(CTYP=6).

Supported options are:

(Integer) |

Example

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/DCOMP/1

dcomp example

# grpartID

1

# CTYP=1 PPMIN PPMAX

1 0.2 2.5

# CTYP=5 BANGLE1 BANGLE2

5 -45.0 45.0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- The option for

selecting the type of drop-off constraints for PDTYP is

defined for a set of plies.The PDTYP options are:

- TOTSLP

- TOTDRP

Figure 1.

Assuming that the plies are stacked as Figure 1, the following definition is:

Figure 2.

Figure 3.

Figure 4.

Figure 5.