HL-T: 1100 Stress Life (S-N) Using Stress History Created from Modal Participation Factors (via a *.pch file) and Modal Stress

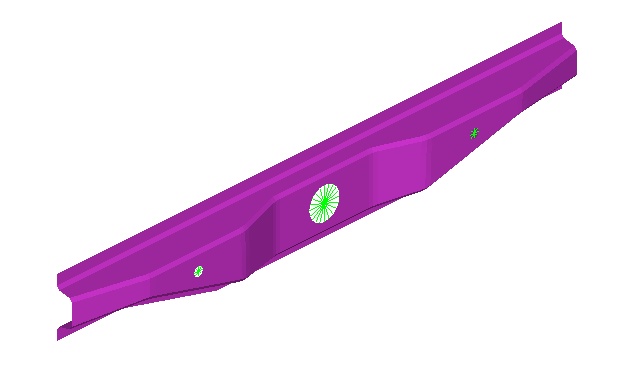

- Import a model to HyperLife

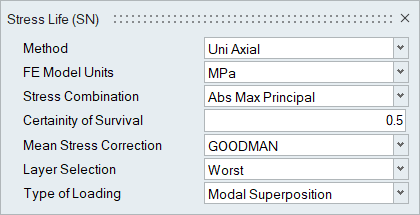

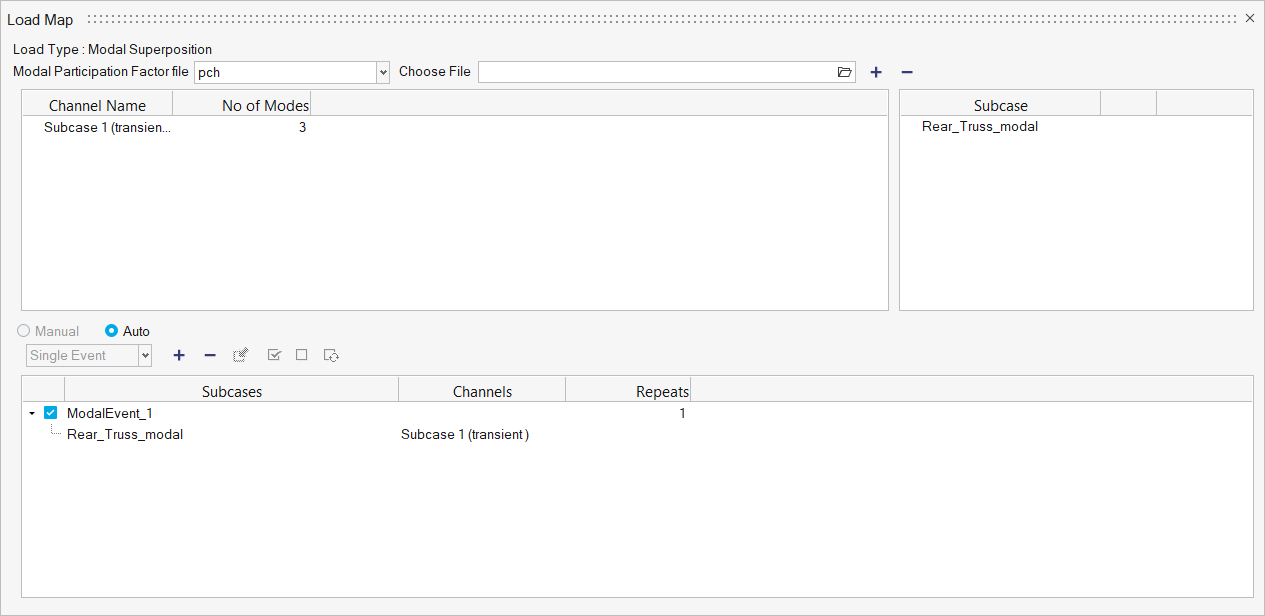

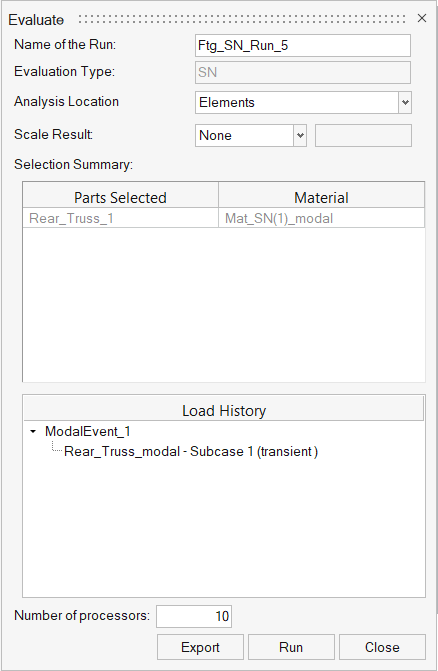

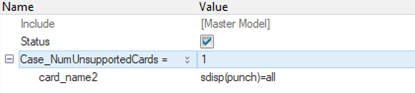

- Select the SN module with a Modal Superposition loading type and define its required parameters

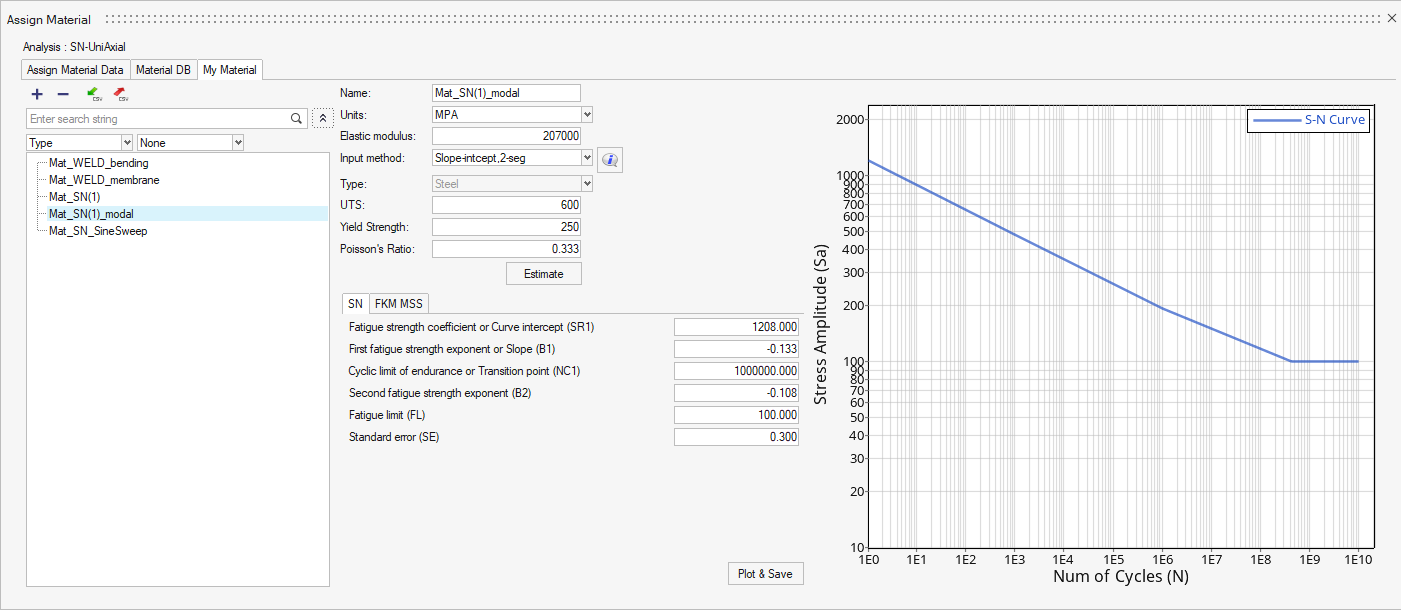

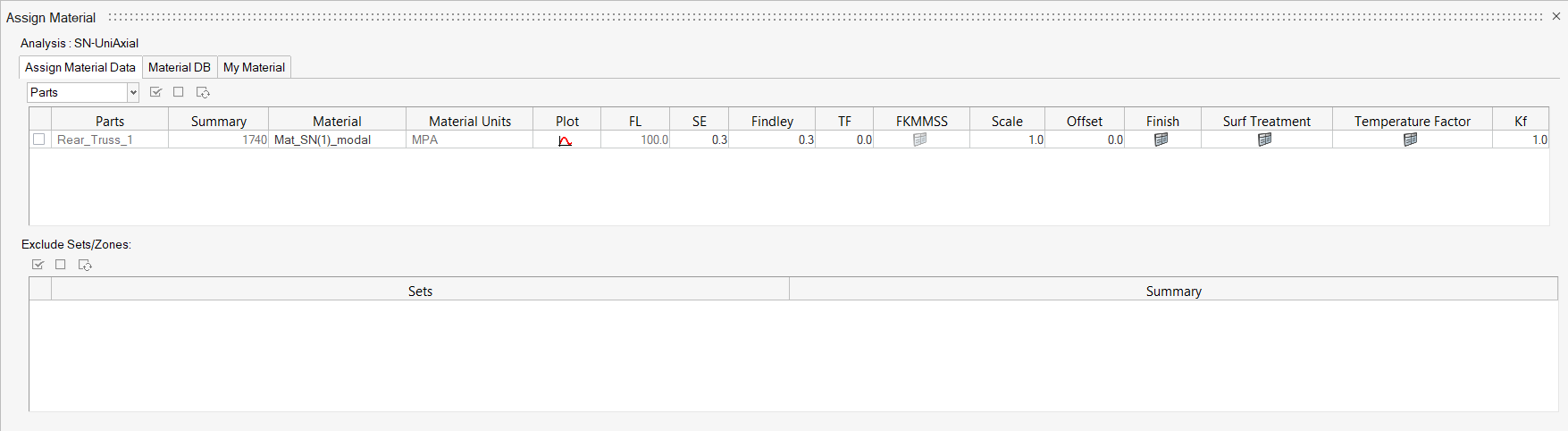

- Create and assign a material

- Assign a *.pch file (containing modal participation factors) to modal stresses

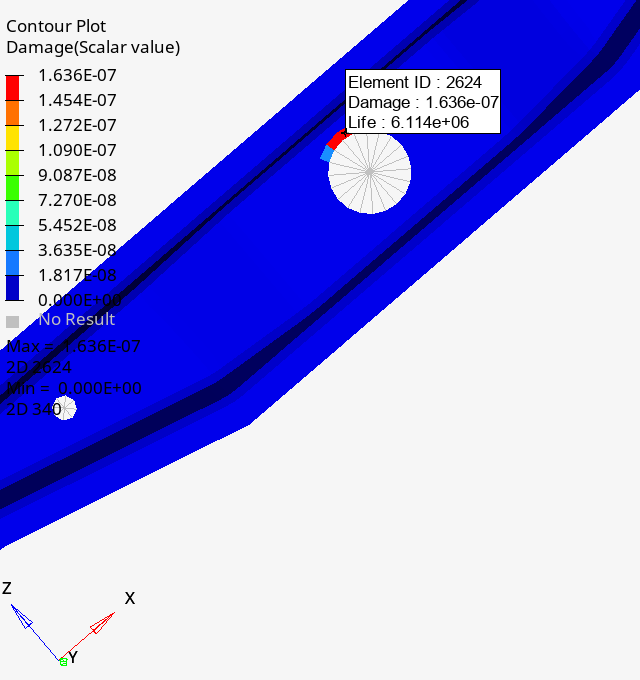

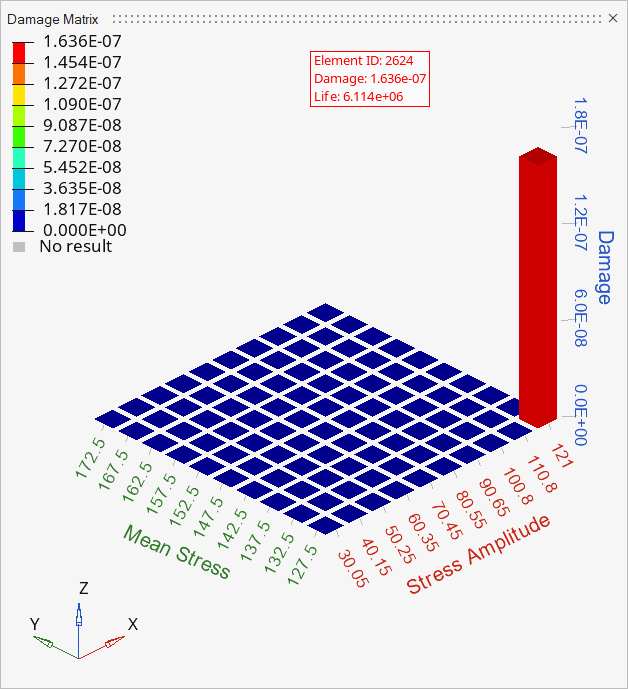

- Evaluate and view results

- HL-1100\Rear_Truss.h3d

- Rear_Truss_modal.pch

- Create stress history from modal participation factors and modal

stresses.For the complete time interval, stress history is given by:Where,

- Stress history for the given time interval of an element

- Participation factor per mode at time t (via mrf/pch file)

- Modal stress of an element per mode (via h3d file)

- Mode

- Perform an SN uniaxial calculation for the above stress history.The above pch file is generated from OptiStruct from a modal transient run.

Figure 1.