Advanced Solution Settings Guidelines

Workflow tips for advanced solution settings in SimSolid.

-

Run linear static analysis

- Identify local deformations, thin curved solids, parts of interest for stresses.

-

Create local groups for identified parts and organize them based on part

scale.

- Group parts with similar scale.

- Apply relevant solution settings (refinement level, adapt to features, adapt to thin solids)

- Adapt to features: Groups where accurate stresses are required

- Adapt to thin solids: Groups where there are thin curved solids

- High refinement level: Global-local analysis and groups with local deformations.

-

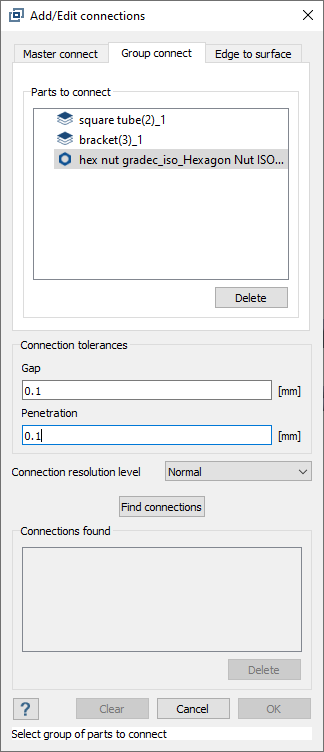

Increase connection resolution (if applicable).

- If stresses around connection are important/high.

- Nonlinear separating/closing contacts.

- If connections cause pivoting/mechanism.

- Do not always use higher resolution on the entire assembly, it will negatively affect the performance of the solution.

Figure 1. Connections > Add/Edit connection

Figure 1. Connections > Add/Edit connection -

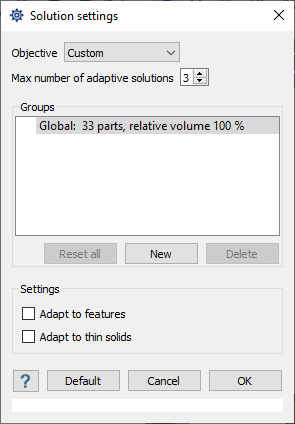

Increase the number of adaptive solutions to 4-5-6 until convergence is

achieved.

Note: Do not go beyond 6 adaptive passes. Higher number of passes cause chatter around contact connections.

Figure 2. Project tree > Solution settings

Figure 2. Project tree > Solution settings - Perform nonlinear analysis only after achieving accurate linear solution.