ACU-T: 5001 Blower - Transient (Sliding Mesh)

Prerequisites

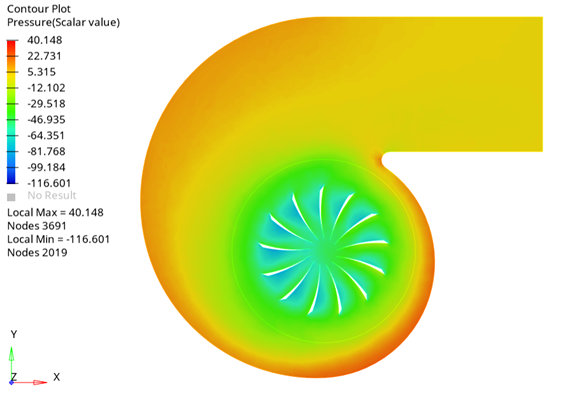

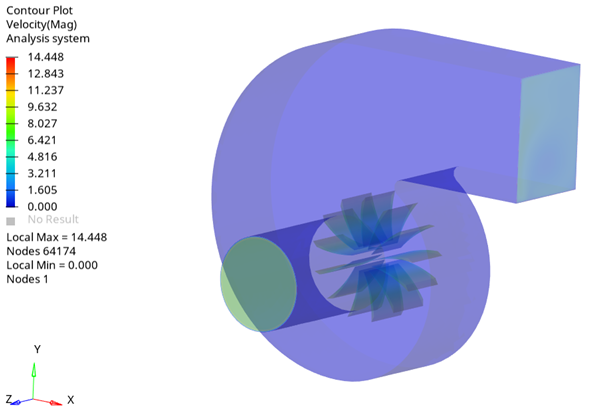

This tutorial provides the instructions for setting up, solving, and viewing results for a transient simulation of a centrifugal air blower utilizing the sliding mesh approach. In order to run this tutorial, you should have already run through ACU-T: 5000 Blower - Steady (Rotating Frame) and kept the solution in your working directory. It is assumed that you have some familiarity with HyperMesh, AcuSolve, and HyperView.

Since the HyperMesh database (.hm file) contains meshed geometry, this tutorial does not include steps related to geometry import and mesh generation.

Problem Description

Figure 1.

Open the HyperMesh Model Database

Run the Steady State Simulation

Set the Transient Simulation Parameters

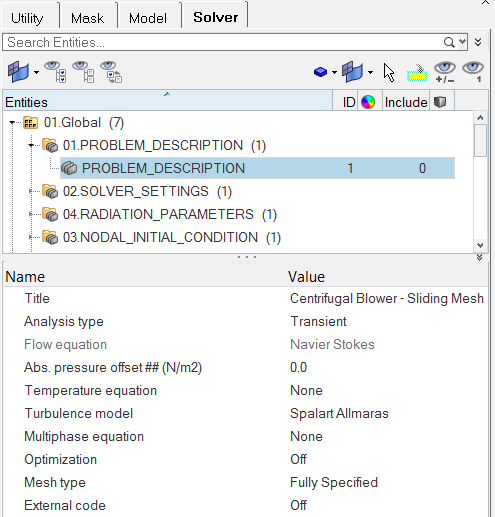

Set the General Simulation Parameters

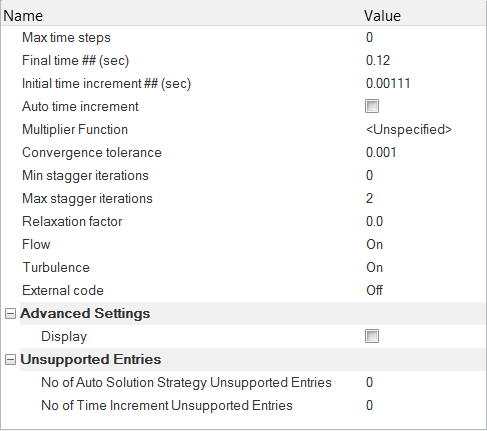

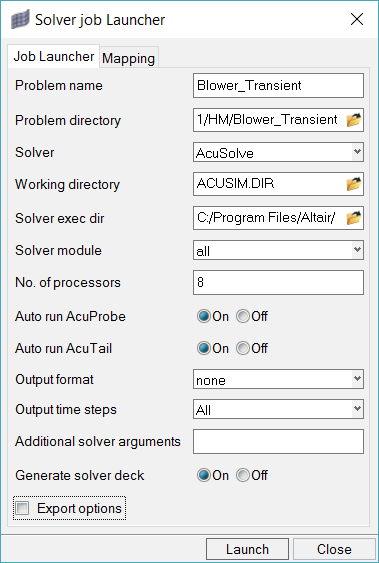

Specify the Solver Settings

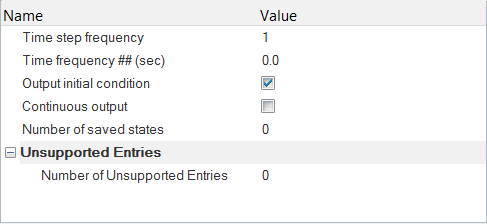

Set the Nodal Output Frequency

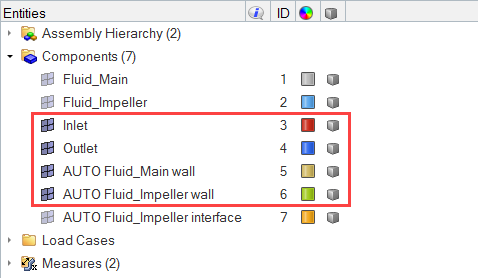

Define Mesh Motion and Set Up Boundary Conditions

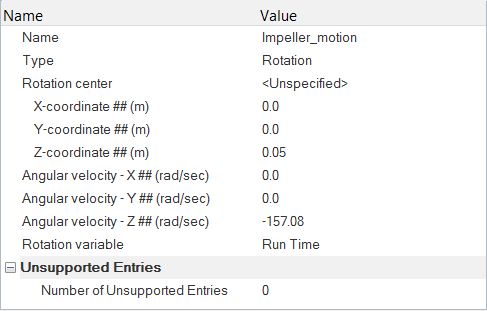

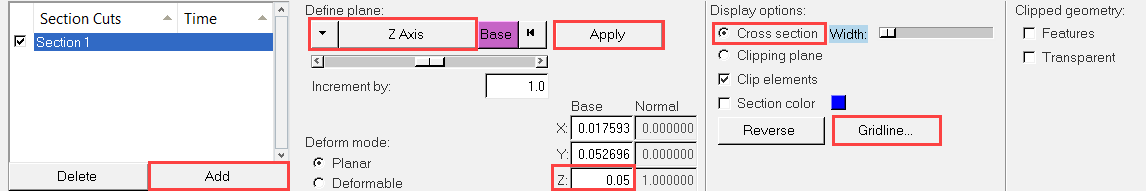

Create Mesh Motion

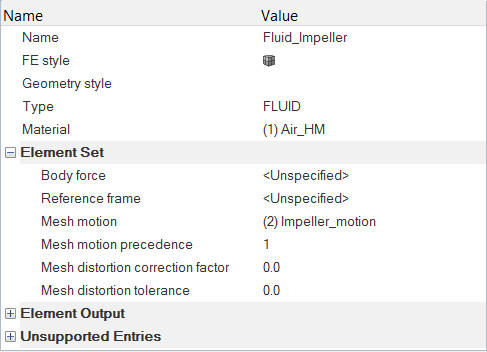

Modify the Boundary Conditions

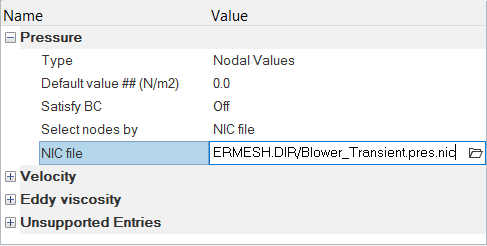

Specify the Nodal Initial Conditions

Compute the Solution

Post-Process the Results with HyperView

Open HyperView and Load the Model and Results

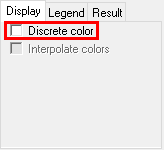

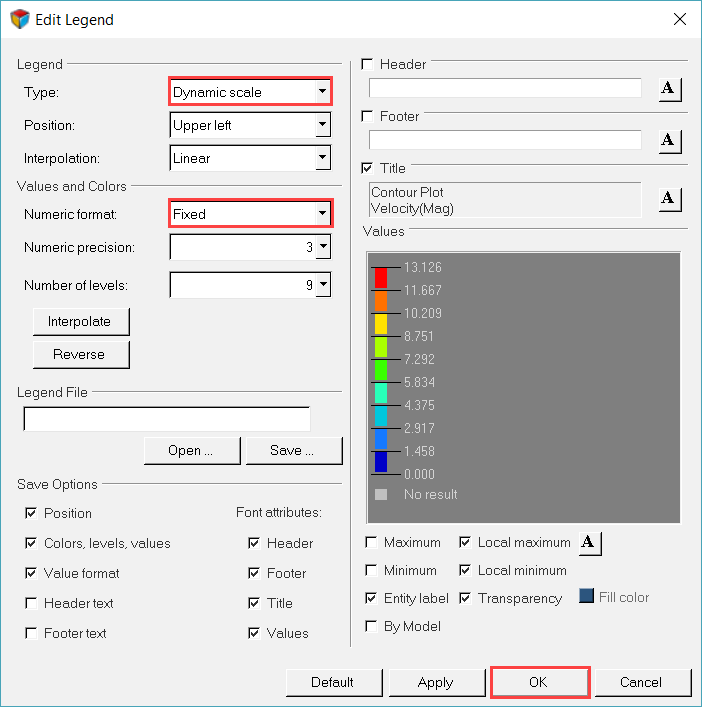

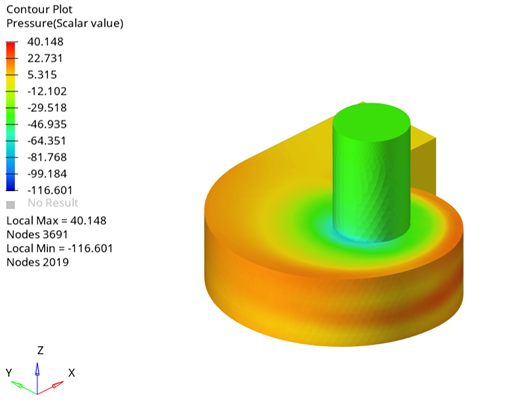

Create a Pressure Animation

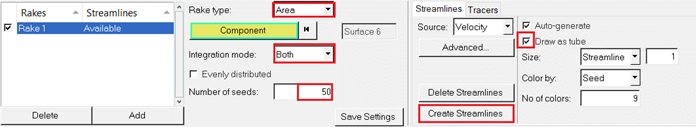

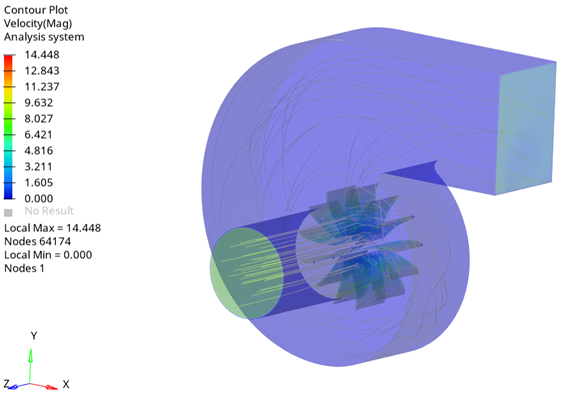

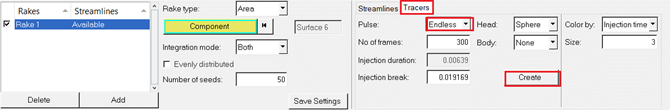

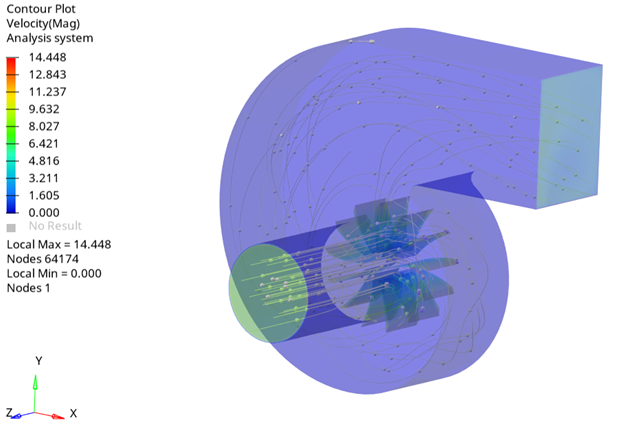

Create Streamlines

Summary

In this tutorial, you successfully learned how to set up and solve a transient simulation of a centrifugal air blower using the sliding mesh approach. You started by importing the meshed geometry and then ran the steady state simulation. Then, you used the steady state result as the starting point for the transient simulation using the AcuProj tool to specify the nodal initial conditions and then solved the transient simulation using the sliding mesh approach instead of the moving reference frame approach. Once the transient solution was computed, you launched HyperView and created an animation of pressure contours and streamlines.

on the Standard Views toolbar.

on the Standard Views toolbar.