Phase 3: Ply Stacking Sequence Optimization

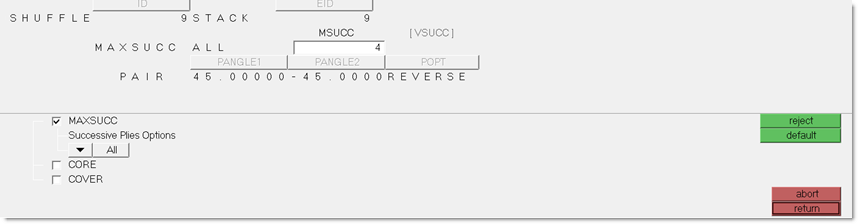

This algorithm is aimed at providing a global view of what the optimal stacking sequence could be. An input deck for the ply stacking sequence optimization, fairing_size_shuffling.*.fem, was generated from a previous design stage. Each ply bundle is divided into multiple PLYs whose thickness is equal to the manufacturable thickness (0.1 in this case), and the STACK card is updated accordingly. In this design phase, composite plies are shuffled to determine the optimal stacking sequence.

- The maximum successive number of plies of a particular orientation does not exceed 4 plies.

- The + 45s and - 45s are reversed paired.

Import the Model

Set Up the Optimization

Update the Composite Strain Response

- From the Analysis page, click the optimization panel.

- Click the responses panel.

- Click response= and select cstrain.

- Using the plies selector, select all of the plies.

- Click update.

- Click return.

Create the Manufacturing Constraints for Shuffling

Run the Optimization

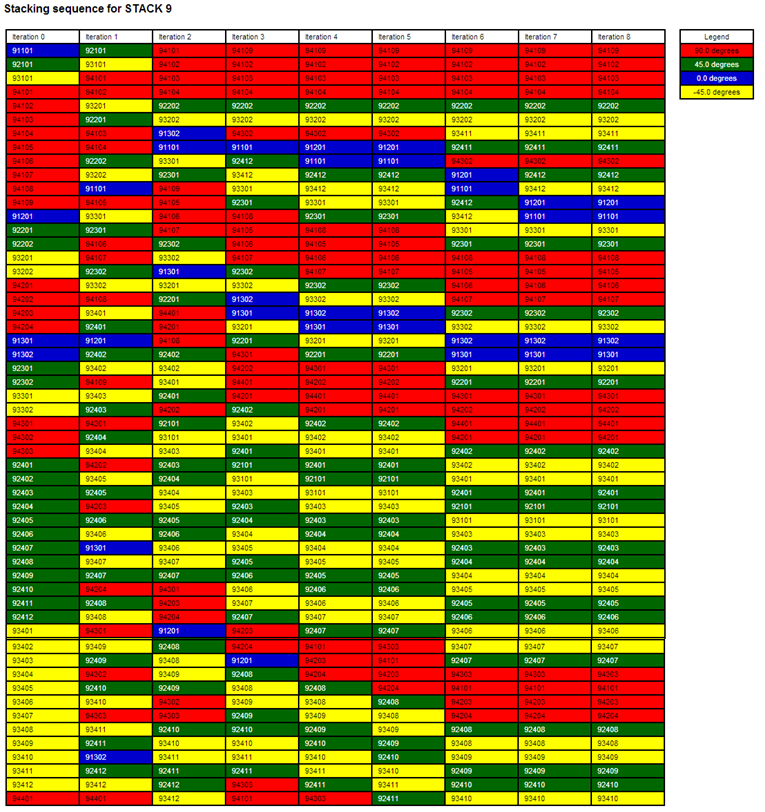

View the Results

Figure 2. Shuffling Optimization History

- Lowest natural frequency = 0.02 KHz (>0.02 KHz)

- Maximum strain = 9.947e-4 (<1.e-3)

.

.