| Damage criteria |

If =1, then failure. If , then no failure.

With

|

If =1, then failure. If , then no failure.

With

|

| Tensile/shear fiber mode |

|

With,

|

| Compression fiber mode |

With

|

With

With

|

| Crush mode |

With

|

With

|

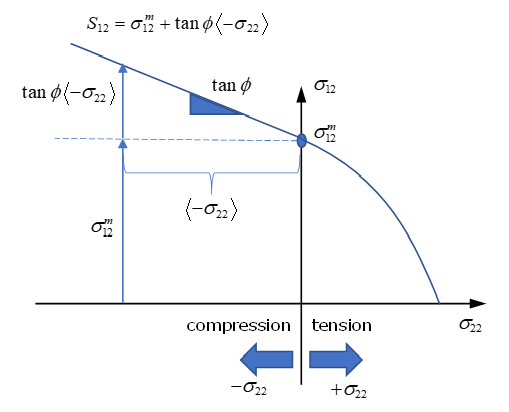

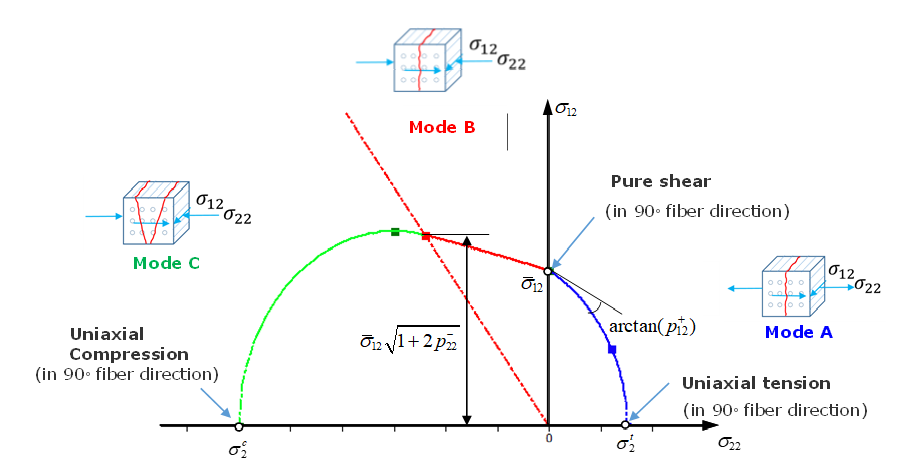

| Shear failure matrix mode |

|

|

| Failure matrix mode |

Where,

|

|

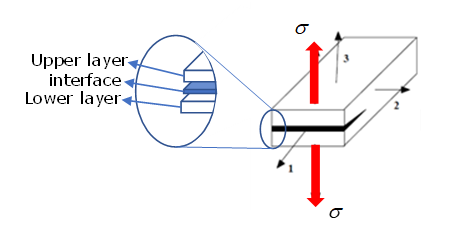

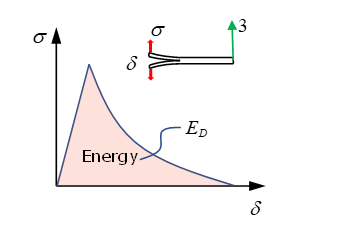

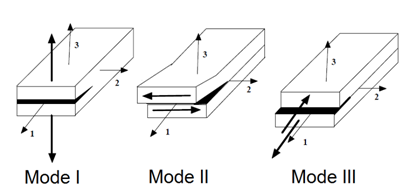

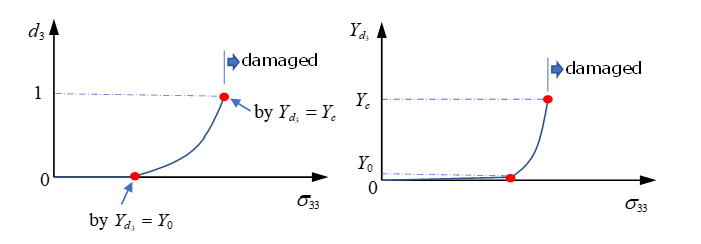

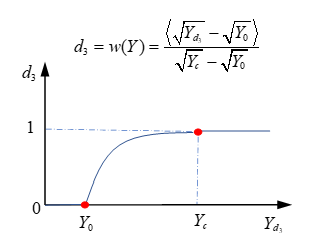

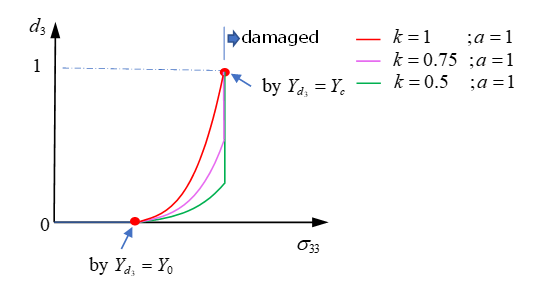

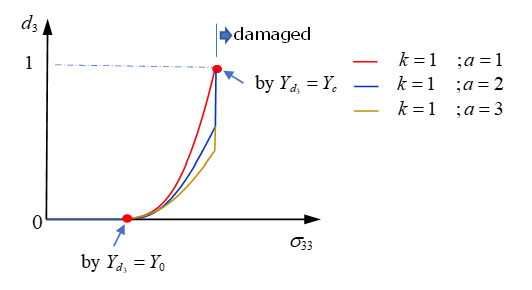

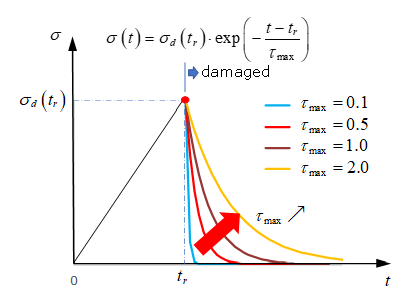

| Delamination mode |

Where,

|

Where,

|