ACU-T: 6104 AcuSolve - EDEM Bidirectional Coupling with Non-Spherical Particles

This tutorial introduces you to the workflow for setting up and running a basic bidirectional coupling (two-way) simulation with non-spherical particles using AcuSolve and EDEM. Prior to starting this tutorial, you should have already run through the introductory HyperWorks tutorial, ACU-T: 1000 Basic Flow Set Up, and have a basic understanding of HyperWorks CFD, AcuSolve, and EDEM. To run this simulation, you will need access to a licensed version of HyperWorks CFD, AcuSolve, and EDEM.

Prior to running through this tutorial, click here to download the tutorial models. Extract the files from the folder named ACU-T6104_EDEM_NonSphericalParticle located in HyperWorksCFD_tutorial_inputs.zip.

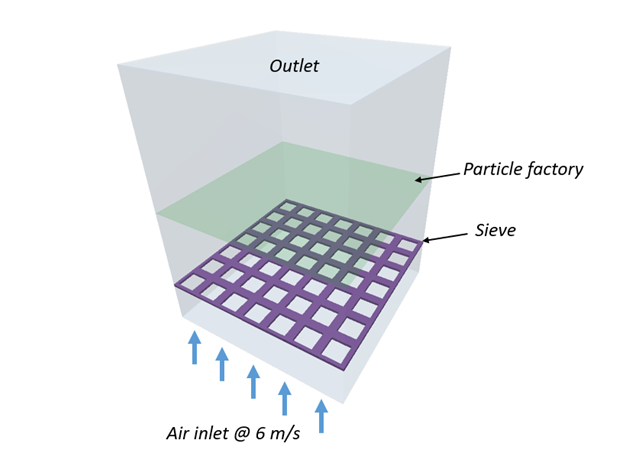

Problem Description

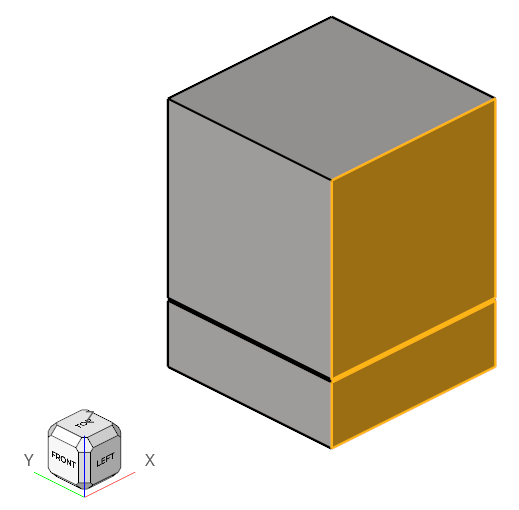

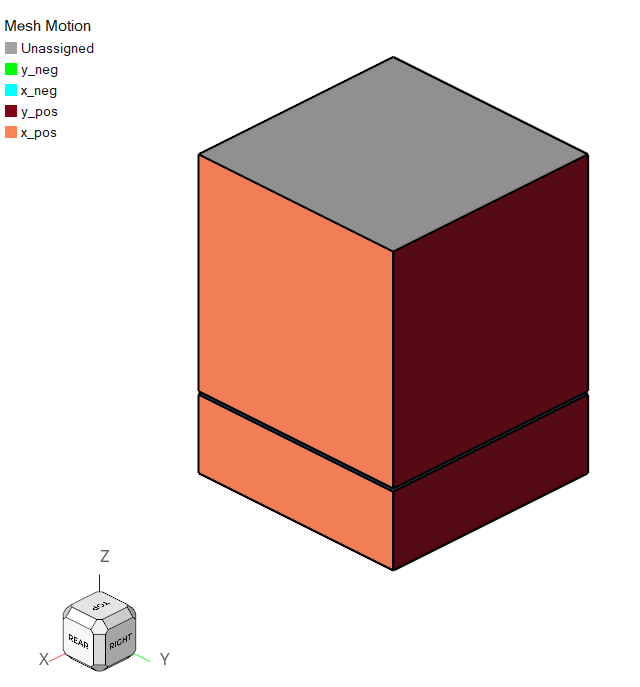

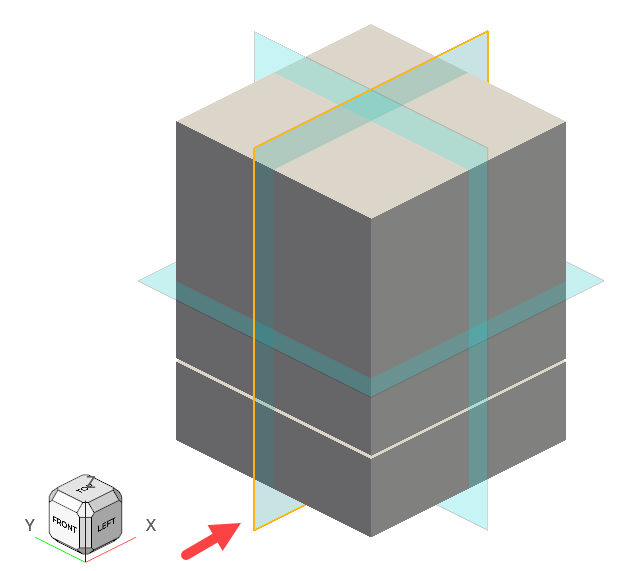

Figure 1.

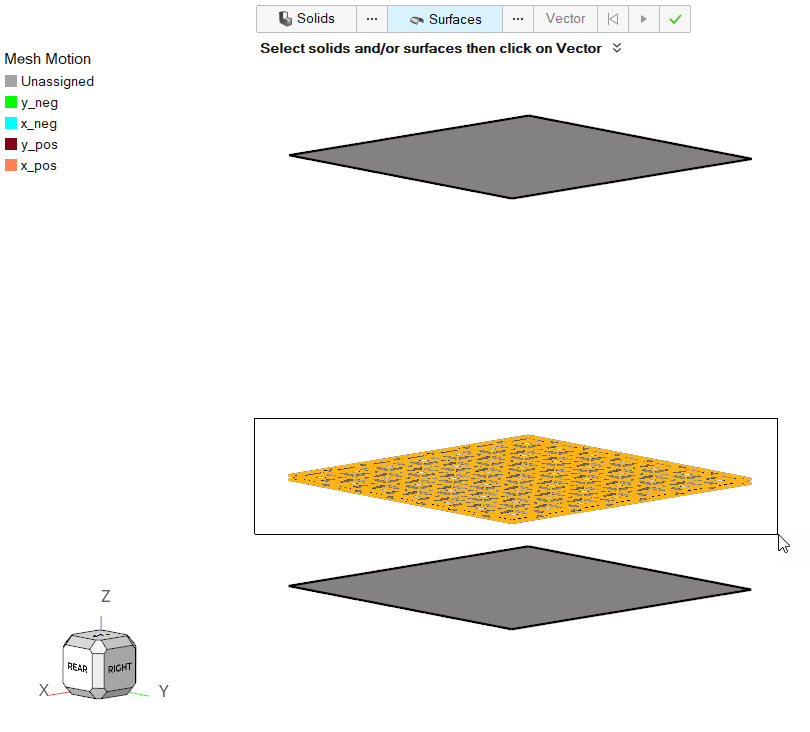

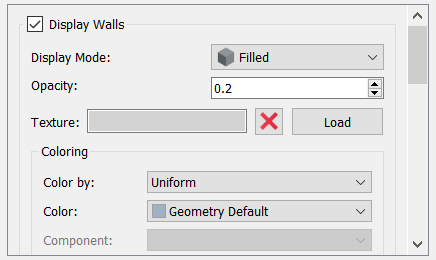

Figure 2.

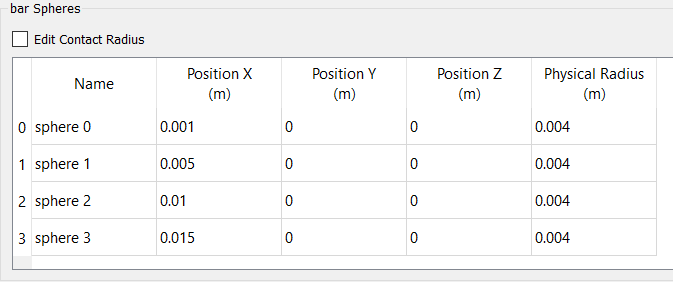

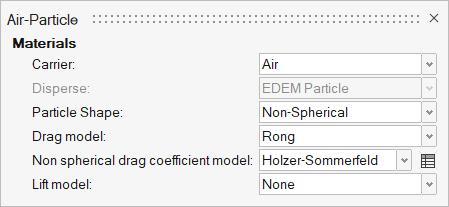

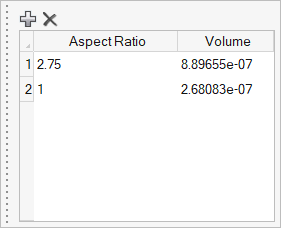

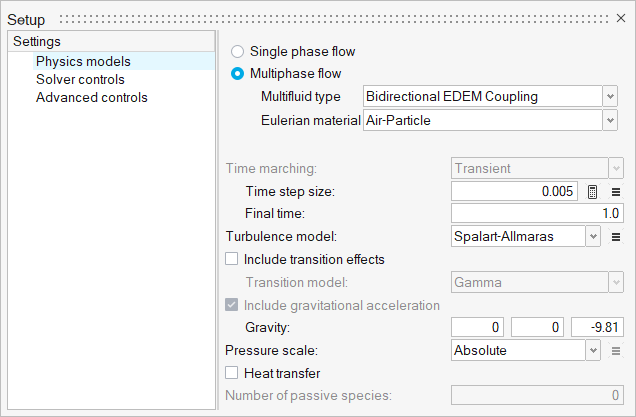

AcuSolve-EDEM bidirectional coupling is used to model the interaction between the fluid and particles. In this tutorial, non-spherical drag force models are used to accurately predict the drag forces on the particles by taking the shape of particles into consideration. The length scale used for factoring in the shape of the particles is the aspect ratio. Bar shaped particles with an aspect ratio of 2.75 and spherical particles with aspect ratio 1 are used for this simulation. The Rong drag model is used in conjunction with the Holzer-Sommerfeld non-spherical drag coefficient model.

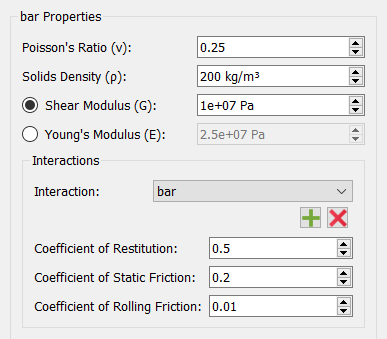

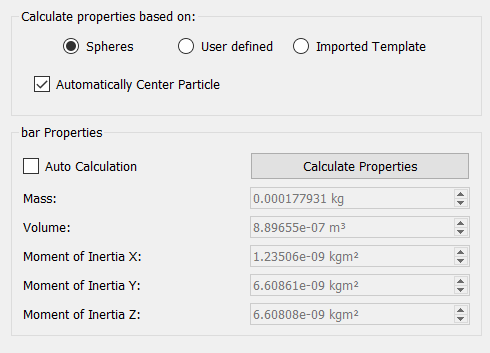

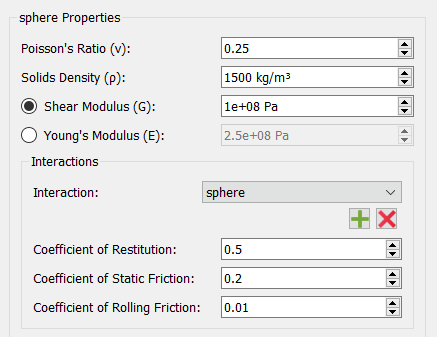

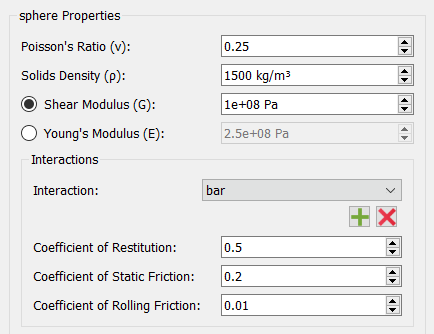

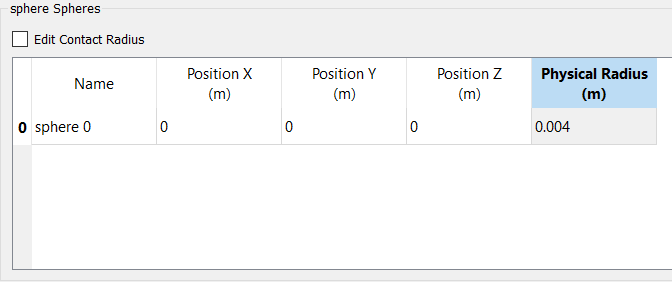

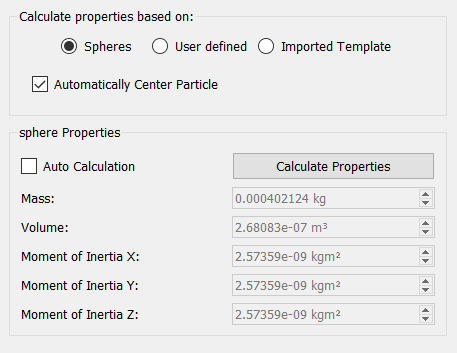

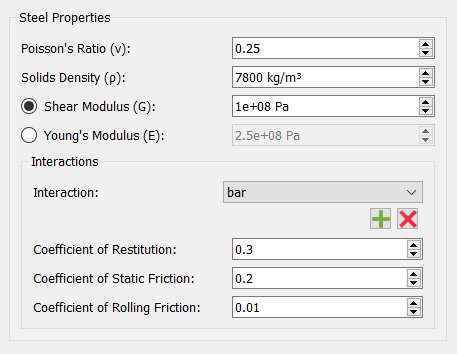

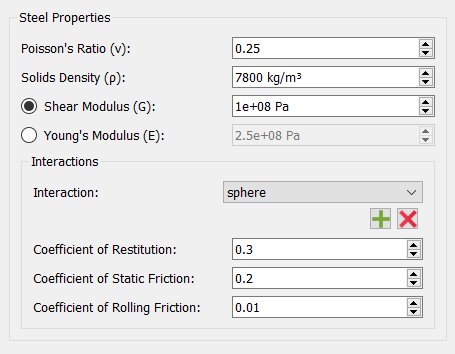

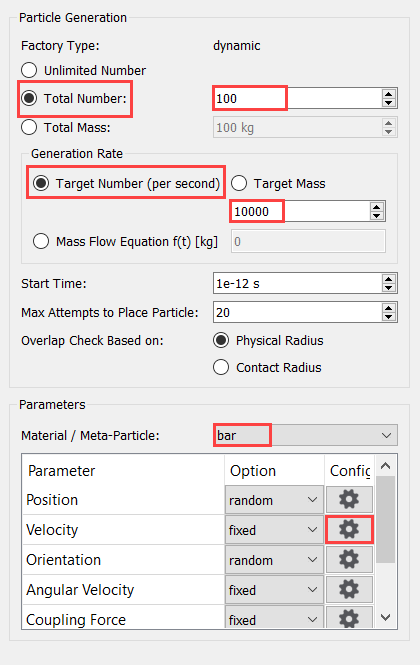

The particle properties used for this simulation are listed in the table below:

| Particle Type | Density (kg/m3) | Size (m) | Number of particles |

|---|---|---|---|

| Bar | 200 | 0.022/0.008 (L/D) | 100 |

| Sphere | 1500 | 0.008 (D) | 200 |

Part 1 - EDEM Simulation

Start Altair EDEM from the Windows start menu by clicking .

Open the EDEM Input Deck

Define the Bulk Materials and Equipment Material

In this step, you will define the material models for the bar and sphere-shaped particles.

Define Geometries and Factories

Define the Environment

In this step, you will define the extents of the domain for the EDEM simulation and the direction of gravitational acceleration.

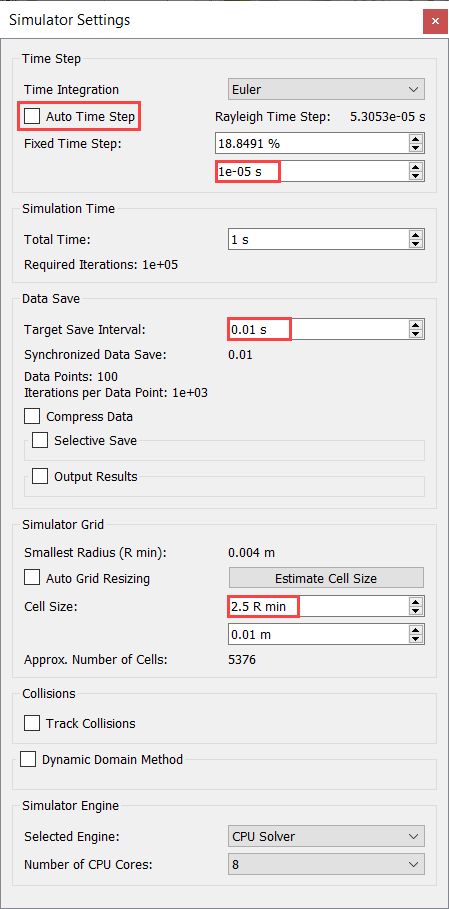

Define the Simulation Settings

Part 2 - AcuSolve Simulation

Start HyperWorks CFD and Open the HyperMesh Database

Validate the Geometry

The Validate tool scans through the entire model, performs checks on the surfaces and solids, and flags any defects in the geometry, such as free edges, closed shells, intersections, duplicates, and slivers.

Figure 17.

Set Up Flow

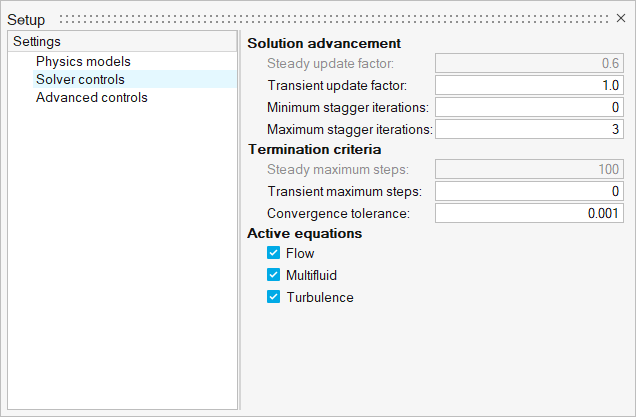

Set the General Simulation Parameters

Assign Material Properties

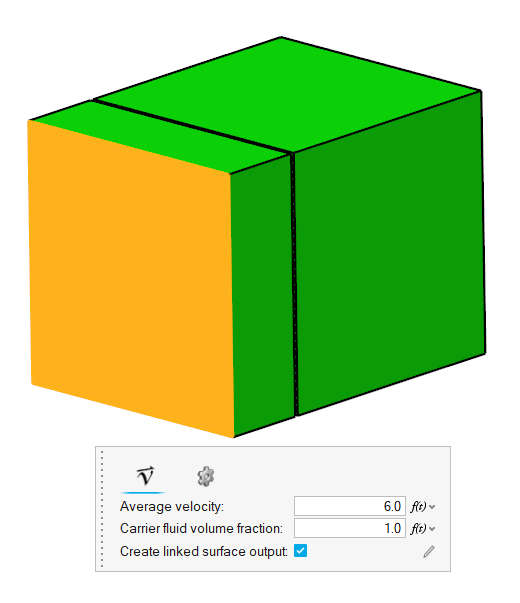

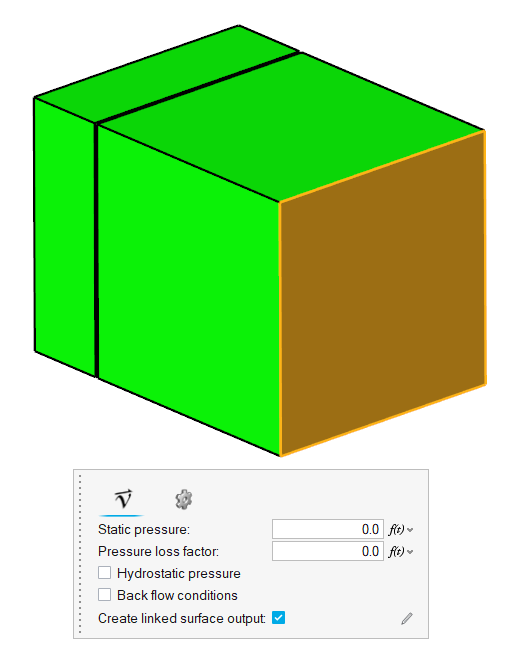

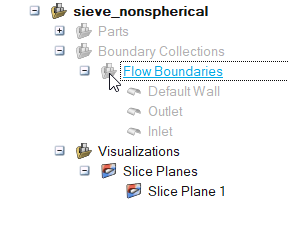

Define Flow Boundary Conditions

Set Up Motion

Select the Motion Type

Define the Mesh Boundary Conditions

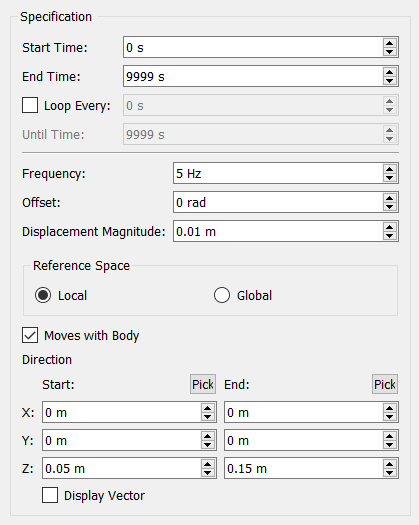

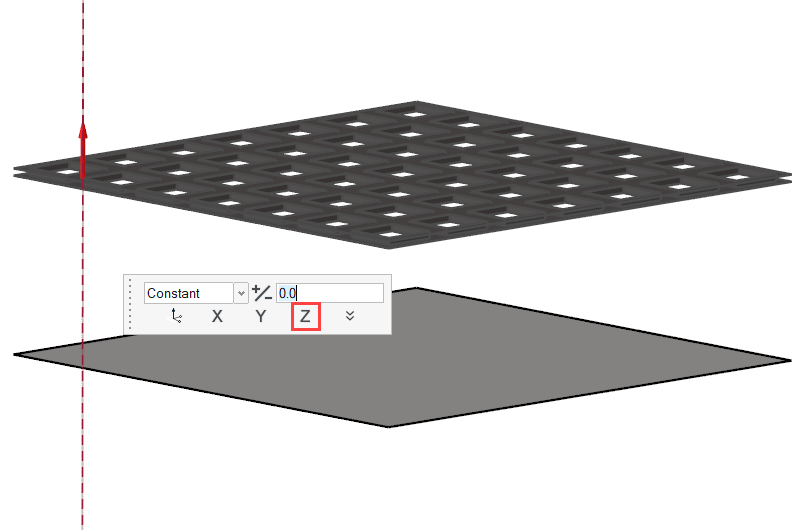

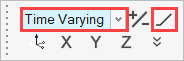

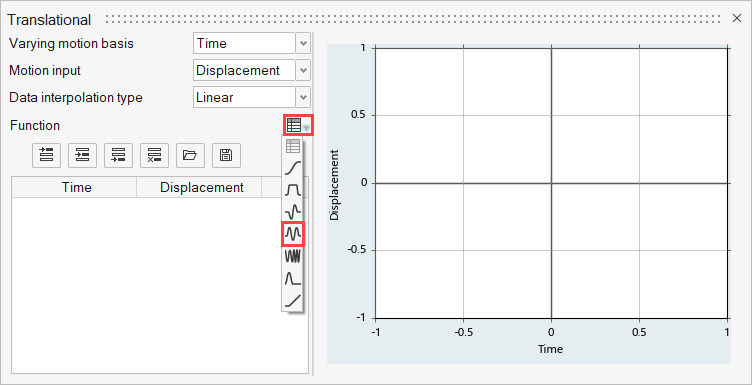

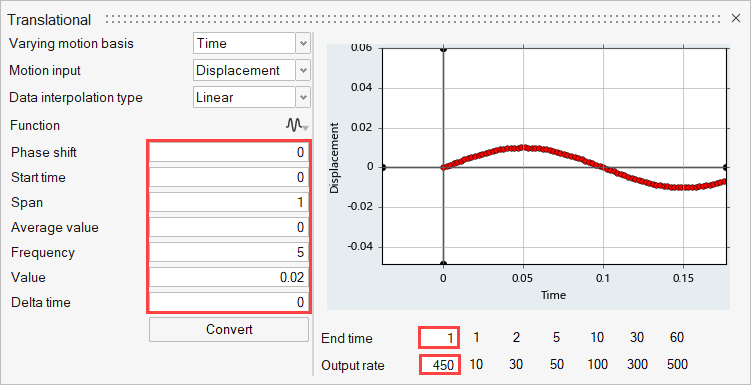

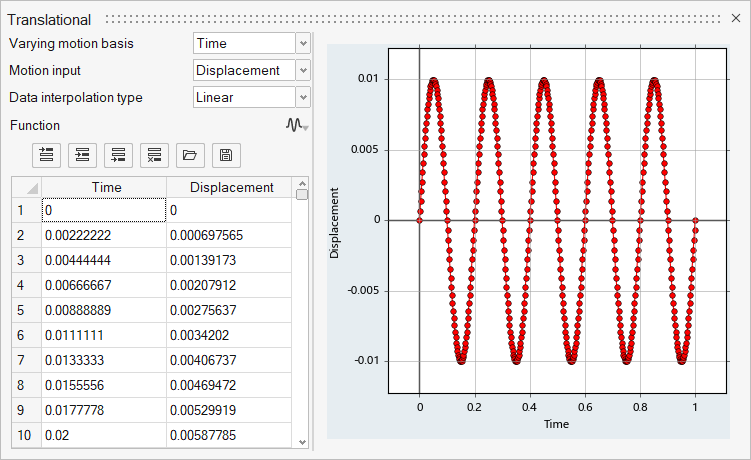

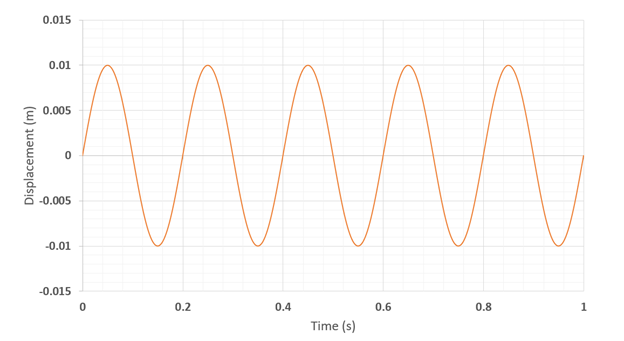

Define Sinusoidal Translational Motion

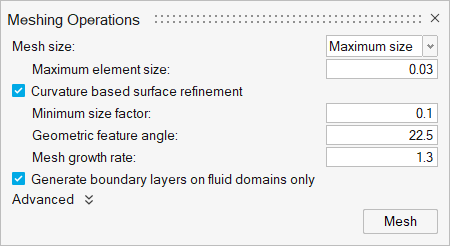

Generate the Mesh

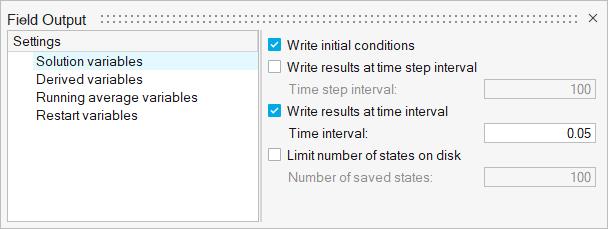

Define Nodal Outputs

Once the meshing is complete, you are automatically taken to the Solution ribbon.

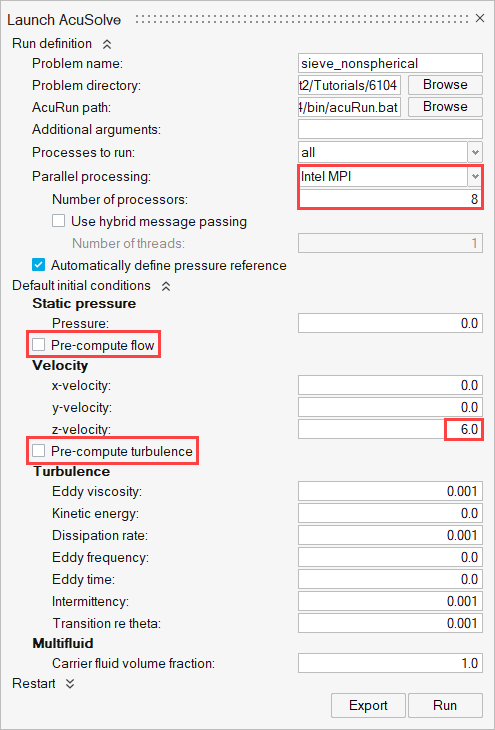

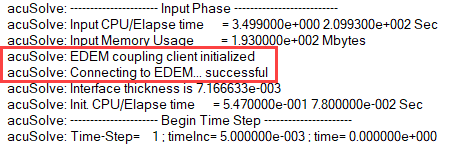

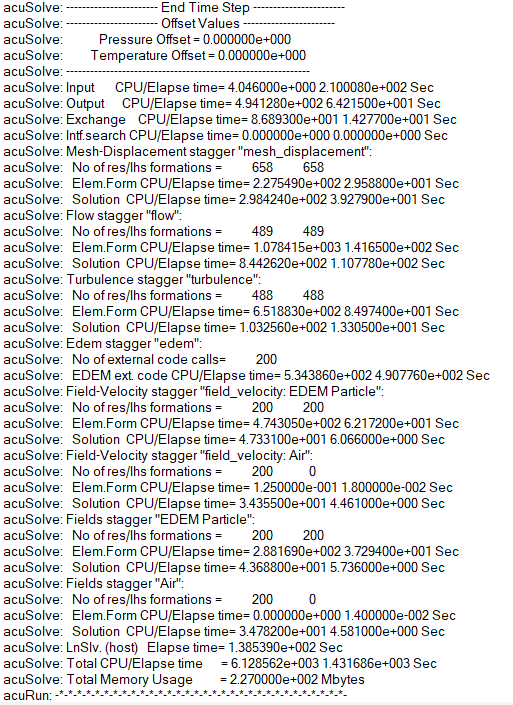

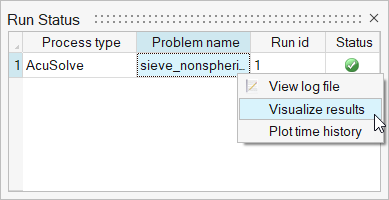

Submit the Coupled Simulation

Analyze the Results

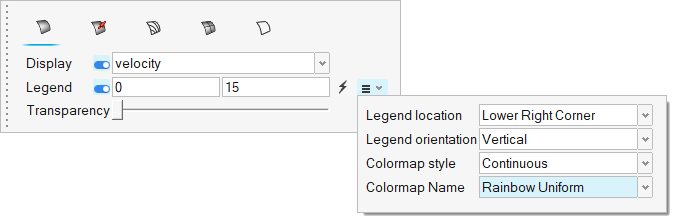

AcuSolve Post-Processing

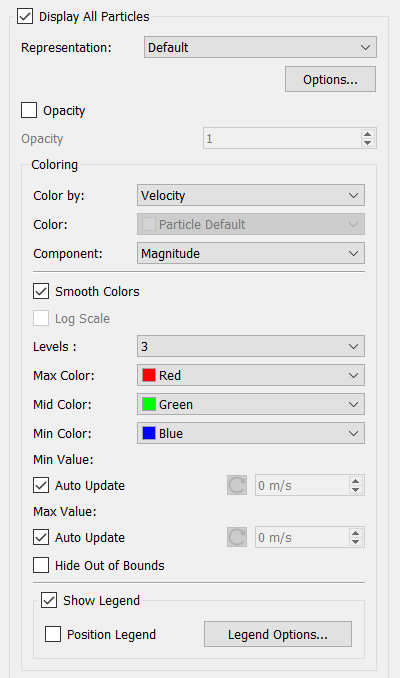

EDEM Post-Processing

Summary

In this tutorial, you learned how to set up and run a basic AcuSolve-EDEM bidirectional (two-way) coupling problem with non-spherical particles. You learned how to create a non-spherical particle in EDEM and set up the AcuSolve model to consider the effect of the particle shape for the fluid-particle interaction forces. Once the simulation was complete, you learned how to post-process the AcuSolve results using HyperWorks CFD and the EDEM results.