Laplacian Smoothing

Laplacian smoothing can be used in the smoothing of the results of topology optimization.

#general parameters

input_file surf

output_file surf.stl

output_code 3

isosurface 1 3 0.300

#specific parameters

laplacian_smoothing 10 30.000 1

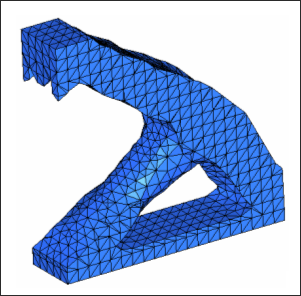

Figure 2. Fix Boundary of Iso-Surface

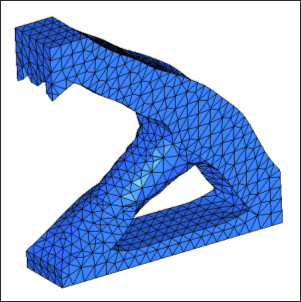

Figure 3. Smooth Boundary of Iso-surface

- The flexibility of controlling the number of smoothing iterations to obtain different degrees of smoothing (possibly a smoothing quality ready for casting). Normally, the iteration number ranges from 5 to 20.

- Smooth boundary of iso-surface with feature angle constrain are seamlessly incorporated into the smoothing process, which is more challenging in a pure CAD system.