OS-V: 0270 Torsional Creep of Circular Shaft

This benchmark illustrates the structural response of a power law creeping material in a geometrical configuration subjected to pure torsion. OptiStruct examines strain at the edge of the shaft.

- Relaxation at constant twist

- Forward creep at steady twist rate

Relaxation at Constant Twist

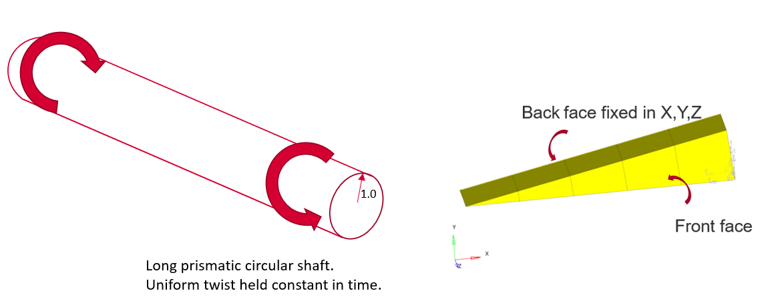

図 1. Model and Loading Description

Benchmark Model

- X, Y displacements given at all nodes of front face using cylindrical system: 0.002 mm

- Rotation is given at mid-side nodes: 0.001 radians

Uniform twist of 0.01 radians/unit length is held constant in time from 0 to 100s.

- Material Properties

- Value

- Young's modulus

- 10 GPa

- Poisson's ratio

- 0.3

- Creep law equation

- Equivalent creep strain rate

- Equivalent stress (Mises)

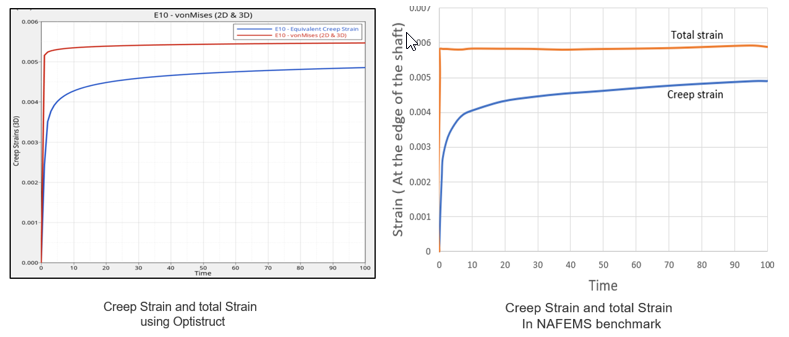

Nonlinear Static Analysis Results

| OptiStruct | NAFEMS | Normalized Target Value | |

|---|---|---|---|

| Total Strain (*10-3) | 5.46 | 5.77 | 0.95 |

| Creep Strain (*10-3) | 4.85 | 4.77 | 1.01 |

図 2. Comparison of Total Strain and Creep Strain at the Edge of the Shaft

Model Files

必要なモデルファイルのダウンロードについては、モデルファイルへのアクセスを参照してください。

The model file used in this example includes:

Torsional_Creep_Relaxation_at_constant_twist.fem

Forward Creep at Steady Twist Rate

A steadily increasing twist is applied at constant rate to the shaft.

The stresses increase from zero to steady value. The loads, which cause this steady-state behavior are referred as “primary” loads.

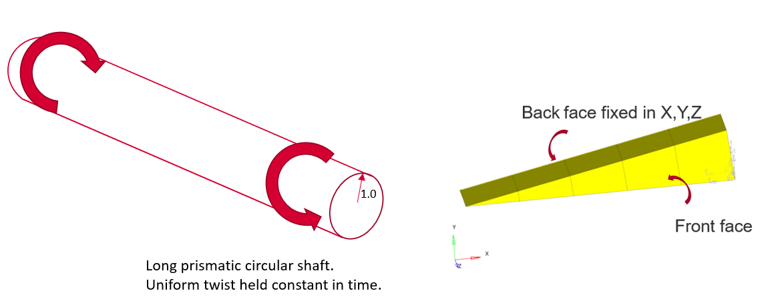

図 3. Model and Loading Description

Benchmark Model

- X, Y displacements given at all nodes of front face using cylindrical system: 0.004 mm/unit time

- Rotation is given at mid-side nodes: 0.002 radians/unit time

- Material Properties

- Value

- Young's modulus

- 10 GPa

- Poisson's ratio

- 0.3

- Creep law equation

- Equivalent creep strain rate

- Equivalent stress (Mises)

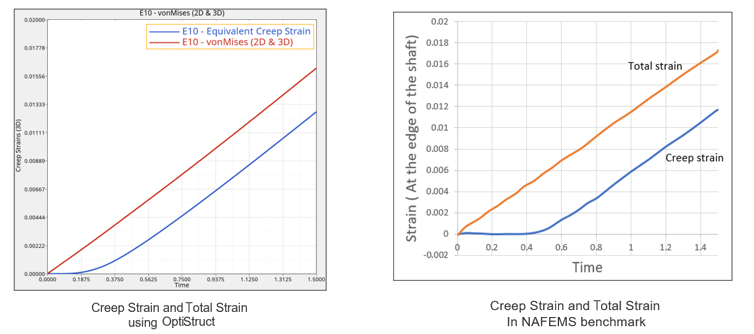

Nonlinear Static Analysis Results

| OptiStruct | NAFEMS | Normalized Target Value | |

|---|---|---|---|

| Total Strain (*10-2) | 1.62 | 1.7321 | 0.94 |

| Creep Strain (*10-2) | 1.27 | 1.1693 | 1.094 |

図 4. Comparison of Total Strain and Creep Strain at the Edge of the Shaft

Model Files

必要なモデルファイルのダウンロードについては、モデルファイルへのアクセスを参照してください。

The model file used in this example includes:

Torsional_forward_creep_at_steady_twist_rate.fem

Reference

NAFEMS R0026 - Selected Benchmarks for Material Non-Linearity- Volume 1