Tutorial: Polymer Coextrusion

Set up and run a coextrusion analysis.

Open the Tutorial Model

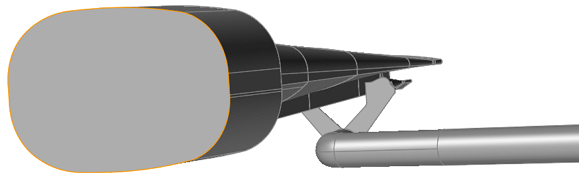

Orient the Model

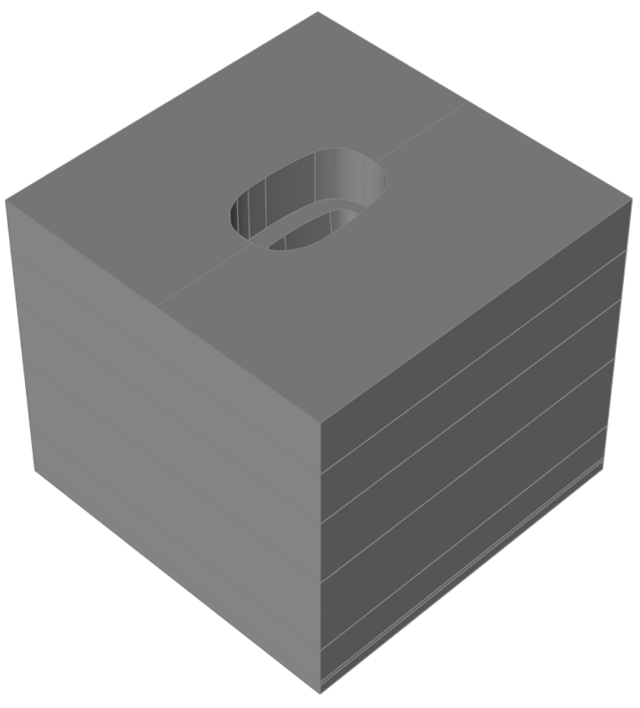

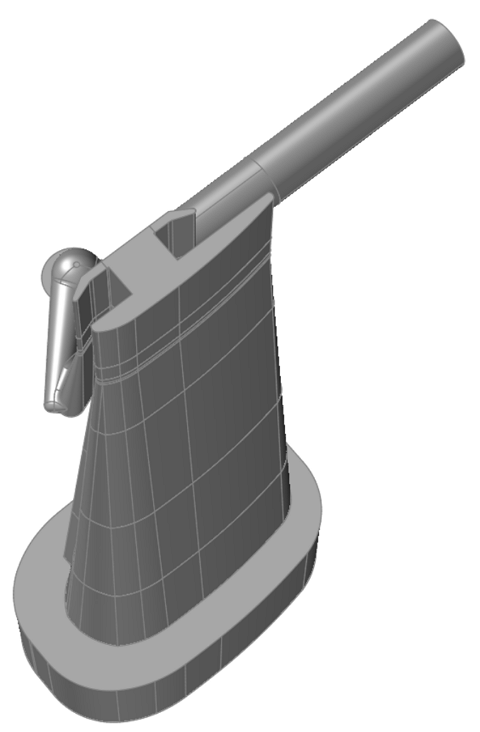

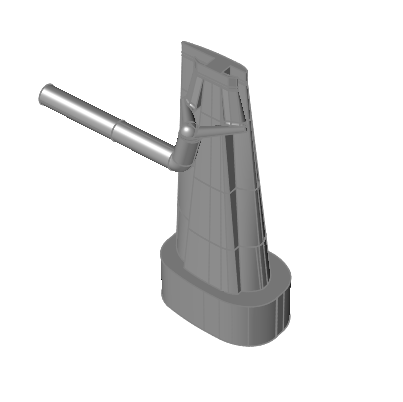

Extract Flow Volume

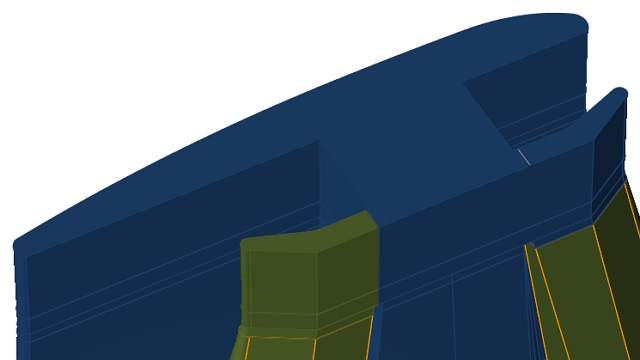

Delete Unwanted Solids

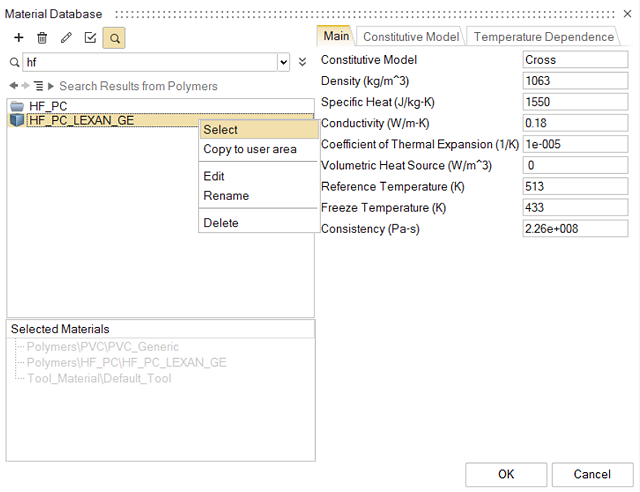

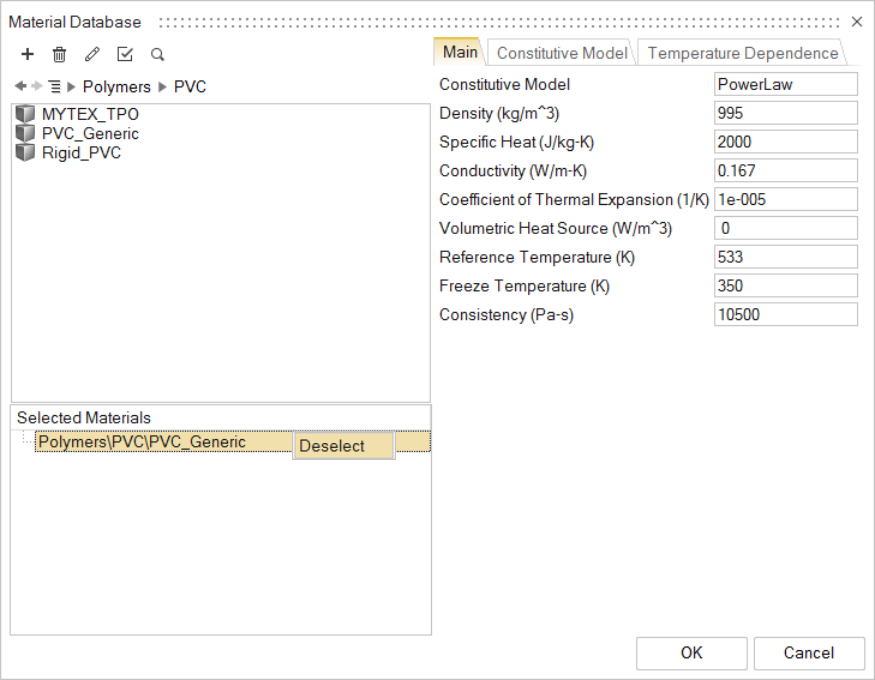

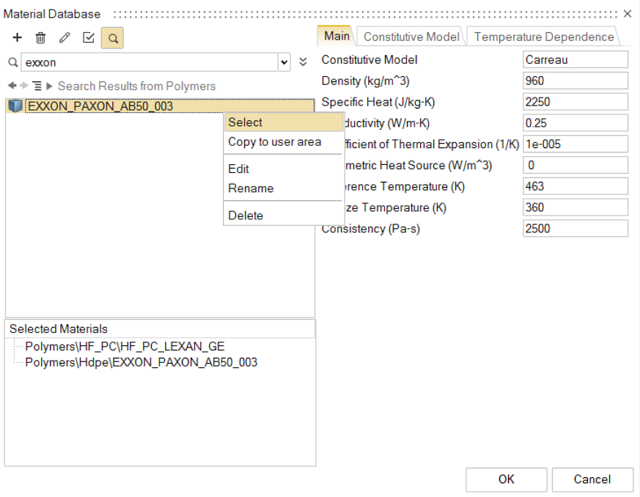

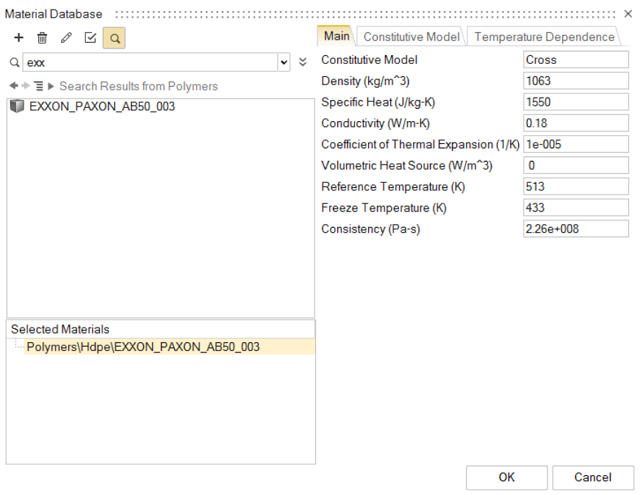

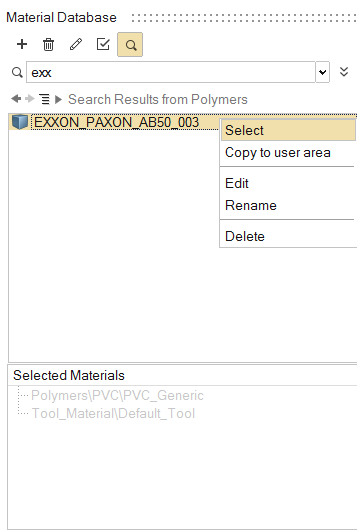

Select Materials

- EXXON_PAXON_AB50_003

- HF_PC_LEXAN_GE

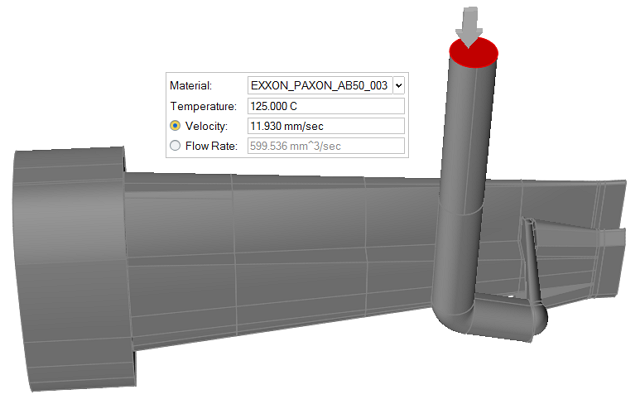

Specify Process Data: Inlets

-

Click the Inlet icon.

-

Zoom in to the first Inlet Region of the Polymer Melt.

-

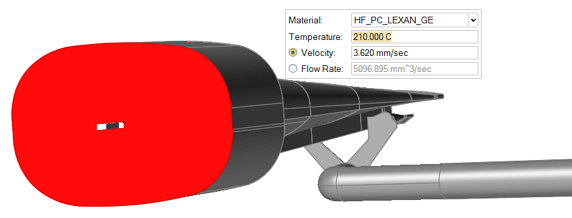

Select the first inlet face. Specify the inlet conditions:

-

Zoom in to the second Inlet Region of the Polymer Melt.

-

Select the second Inlet face. Specify the inlet conditions:

- Right-click and mouse through the check mark to exit, or double-right-click.

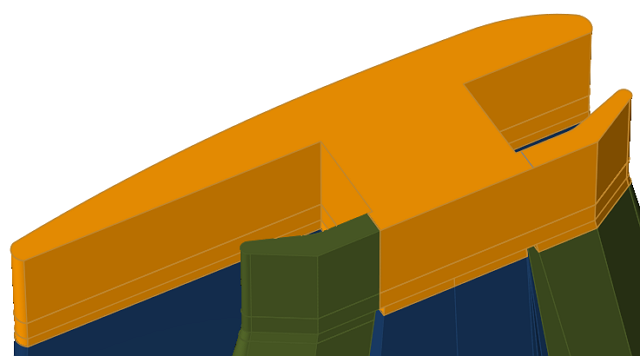

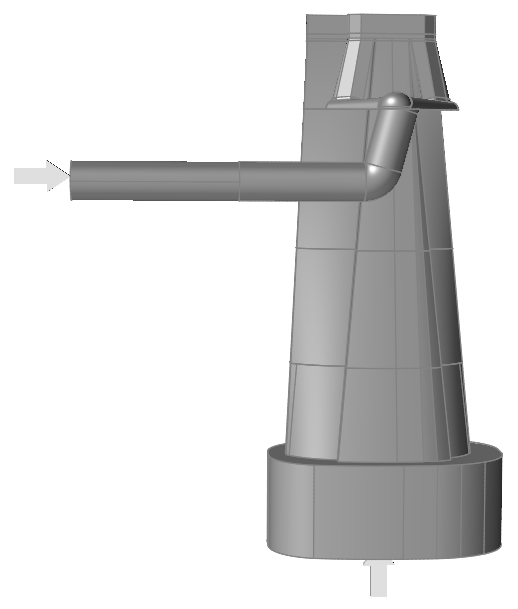

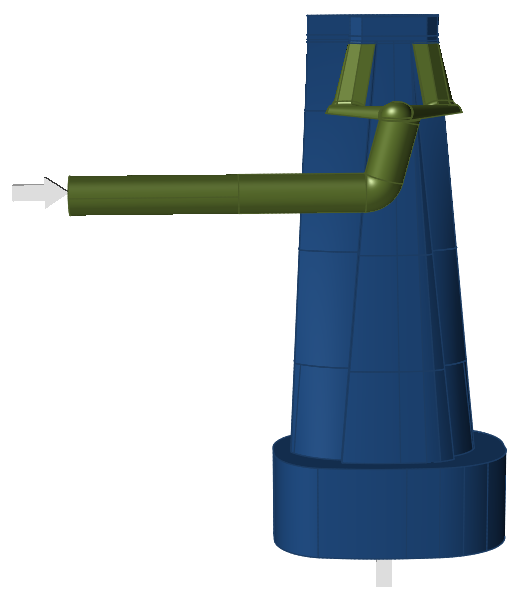

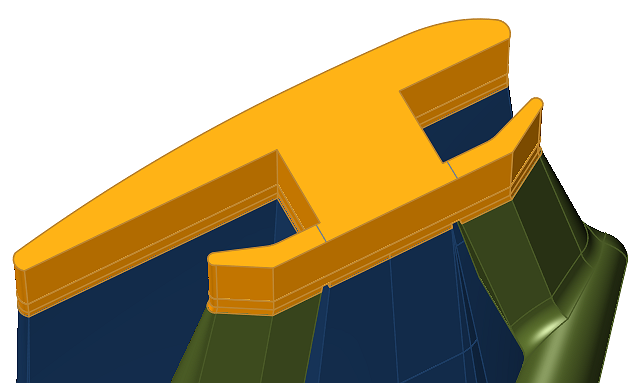

Organize Solids Into Polymer Layers

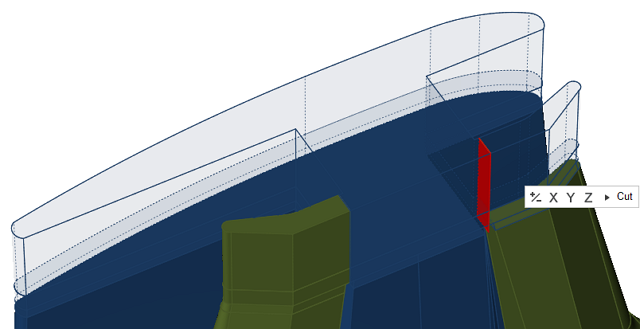

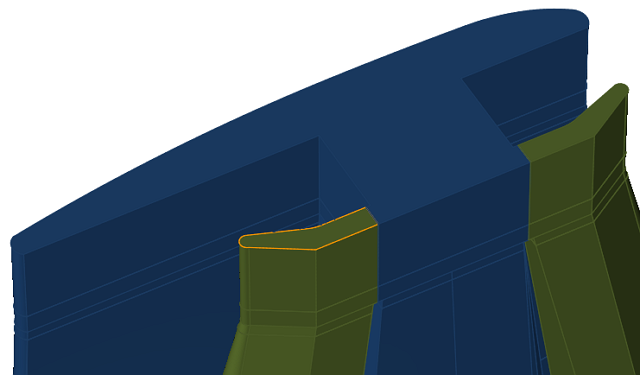

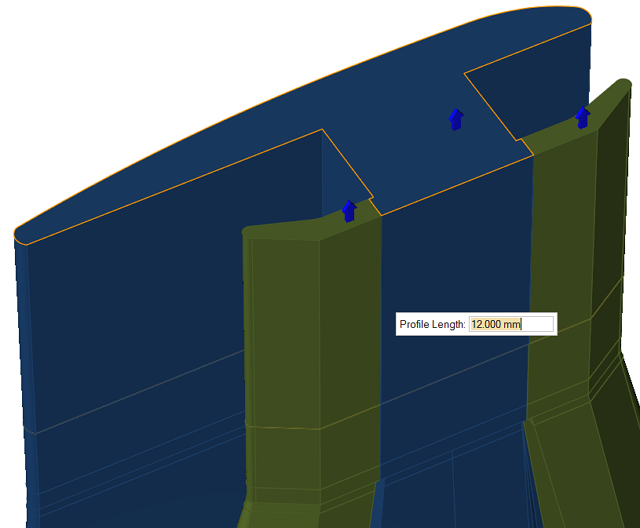

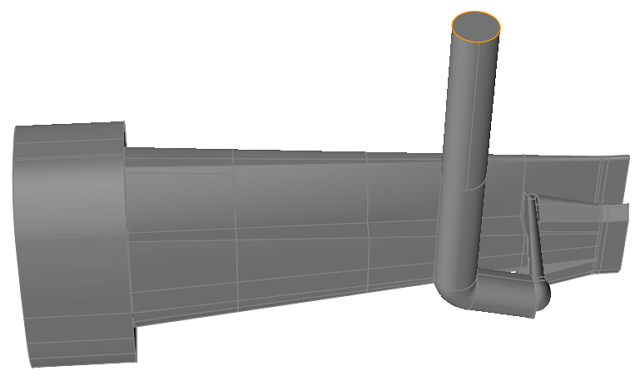

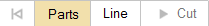

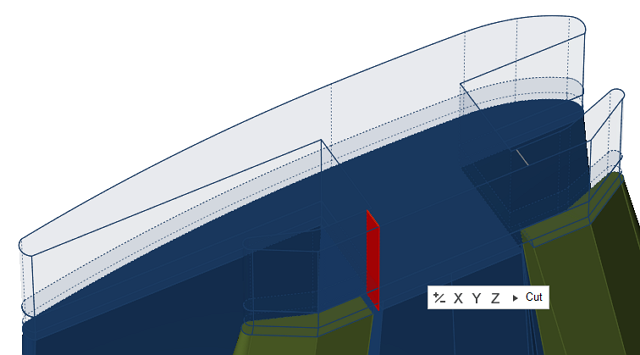

Cut Land

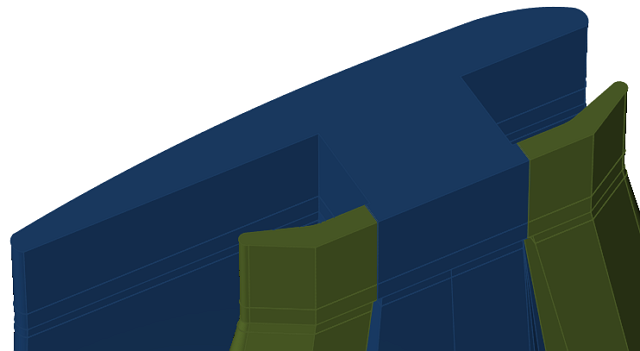

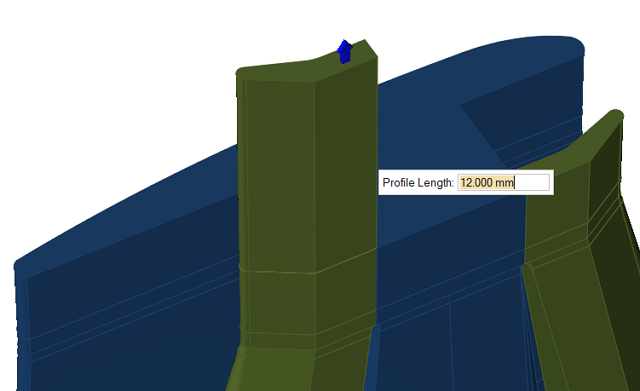

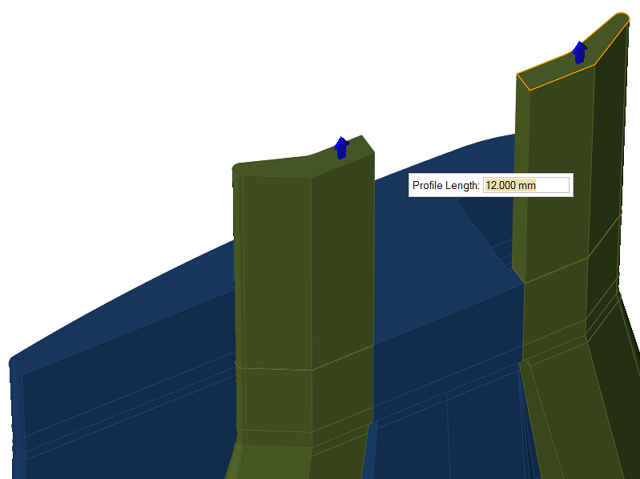

Create Profile Solids

Save Model

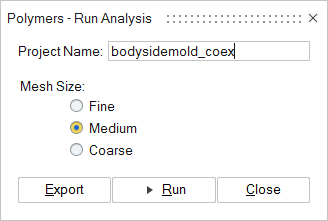

Submit the Job for Simulation

-

Click the Analysis icon.

-

Specify the parameters of the analysis process.

- Click Run.

Monitor Job Status

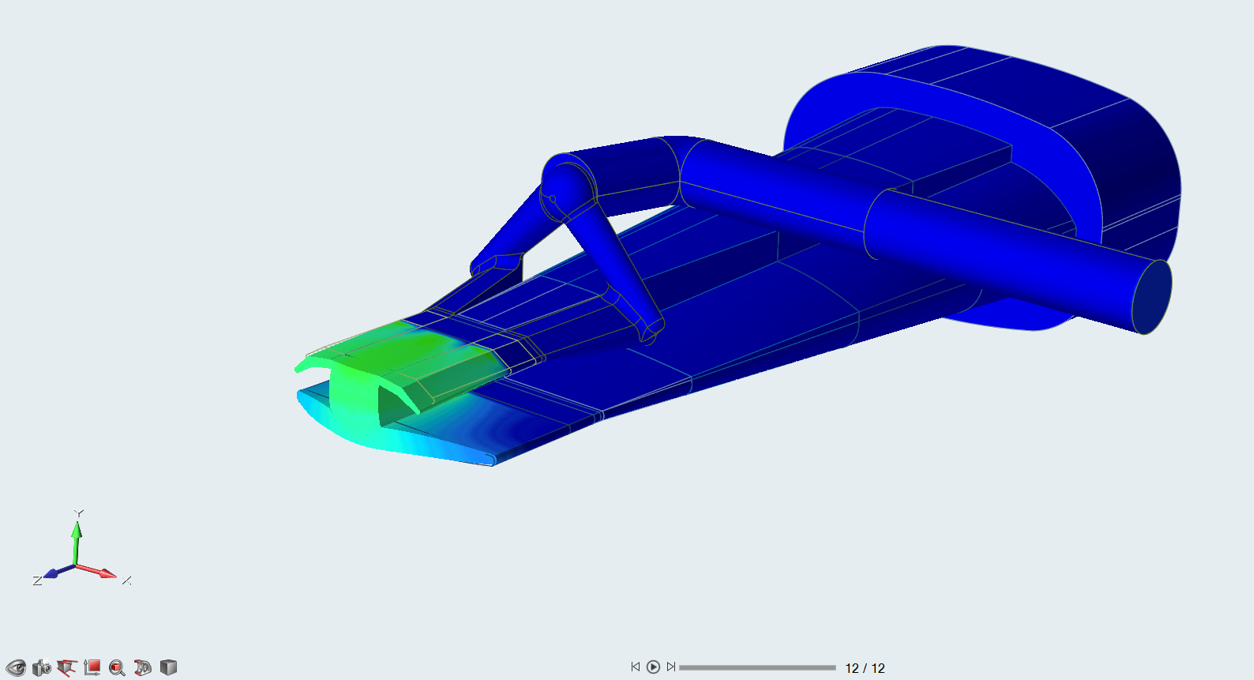

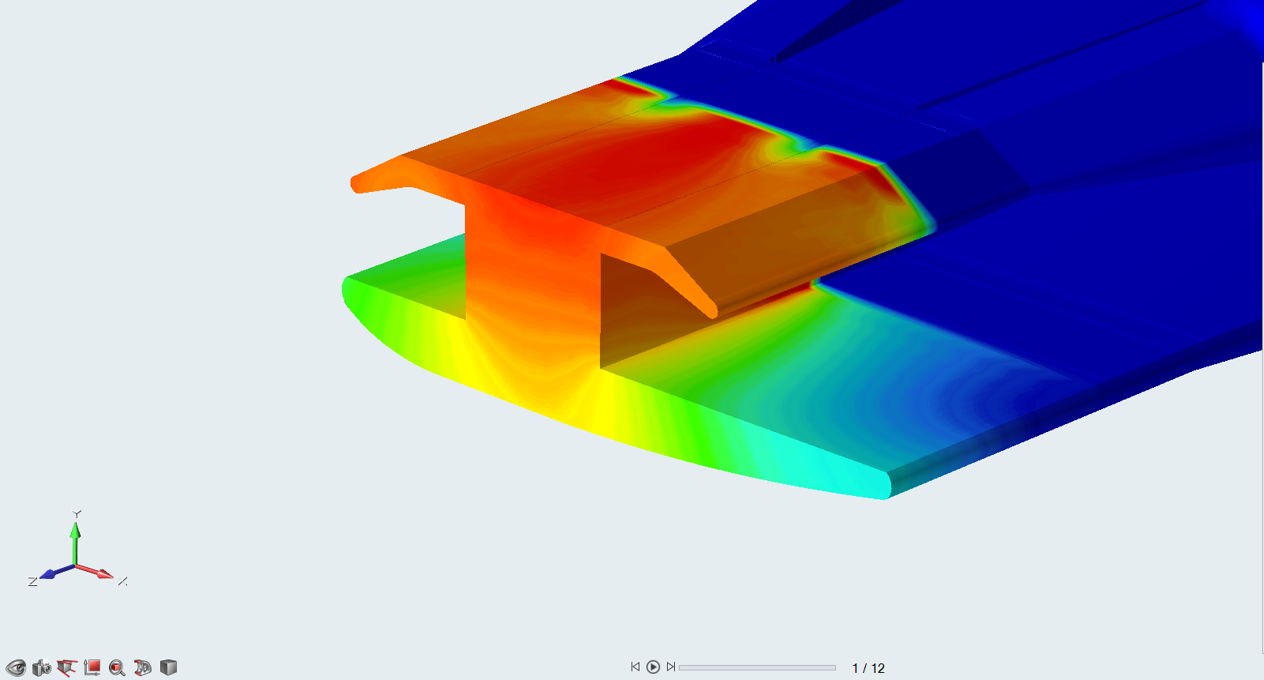

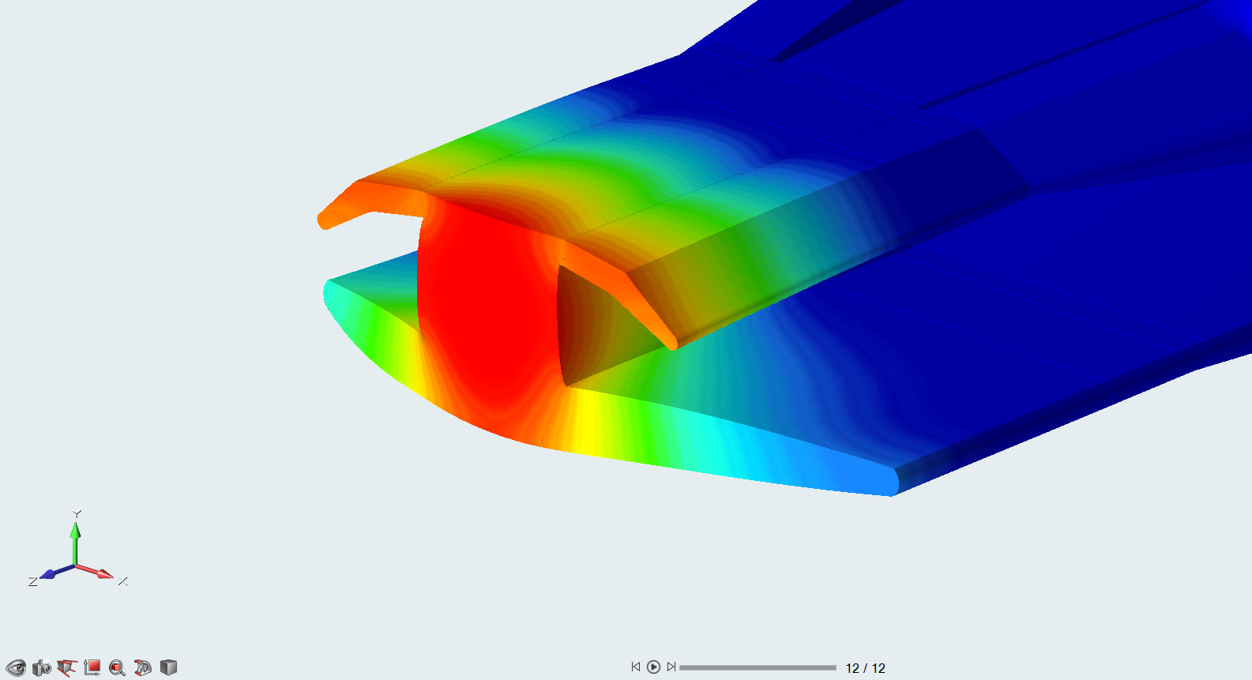

View Simulation Results

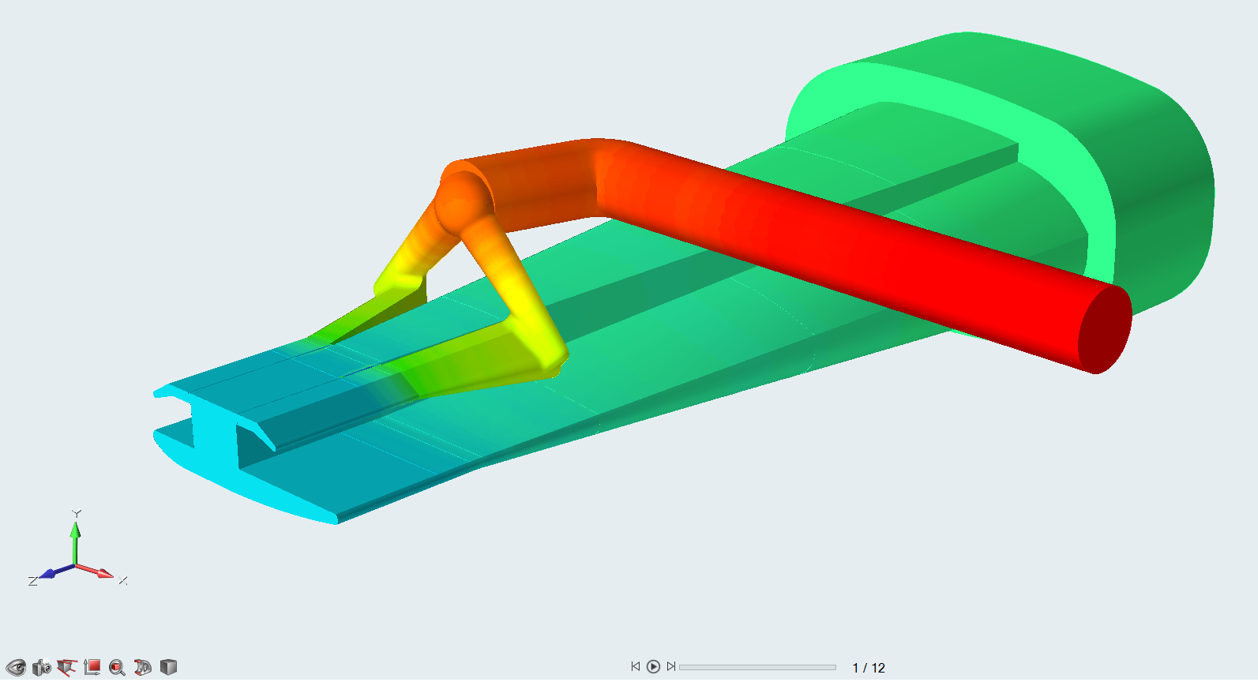

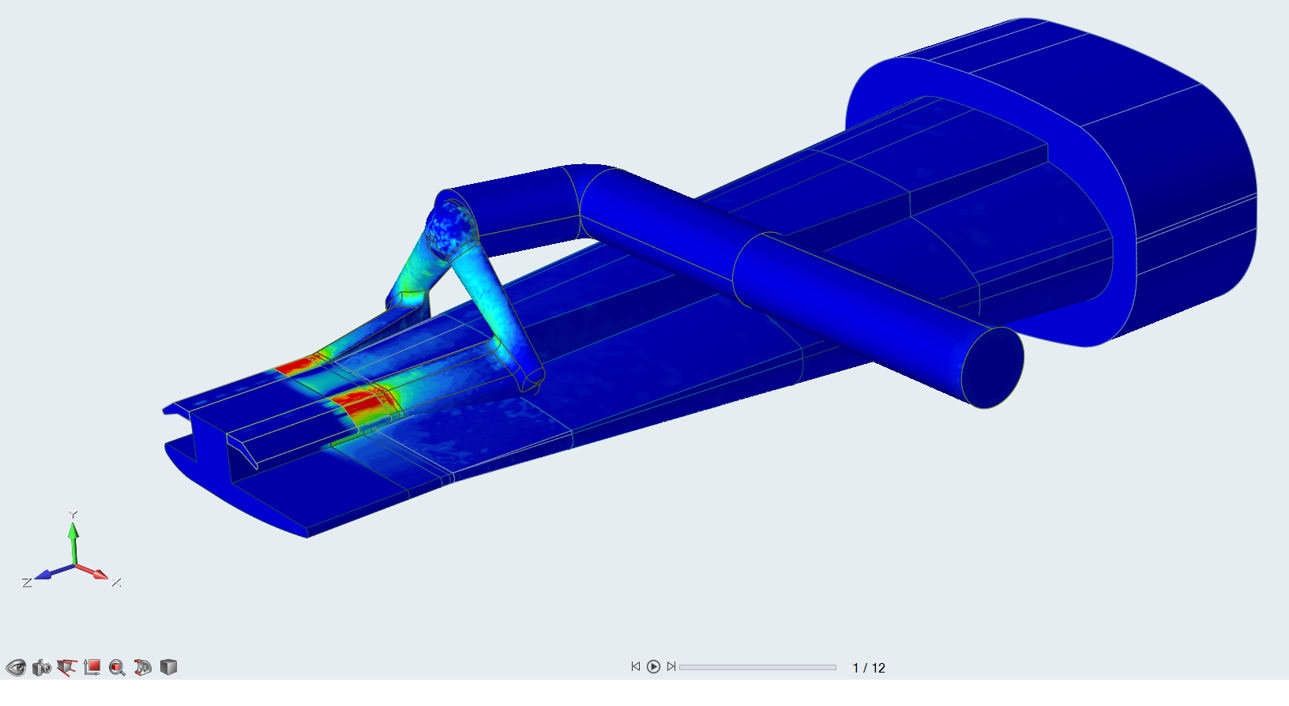

Figure 1. Velocity

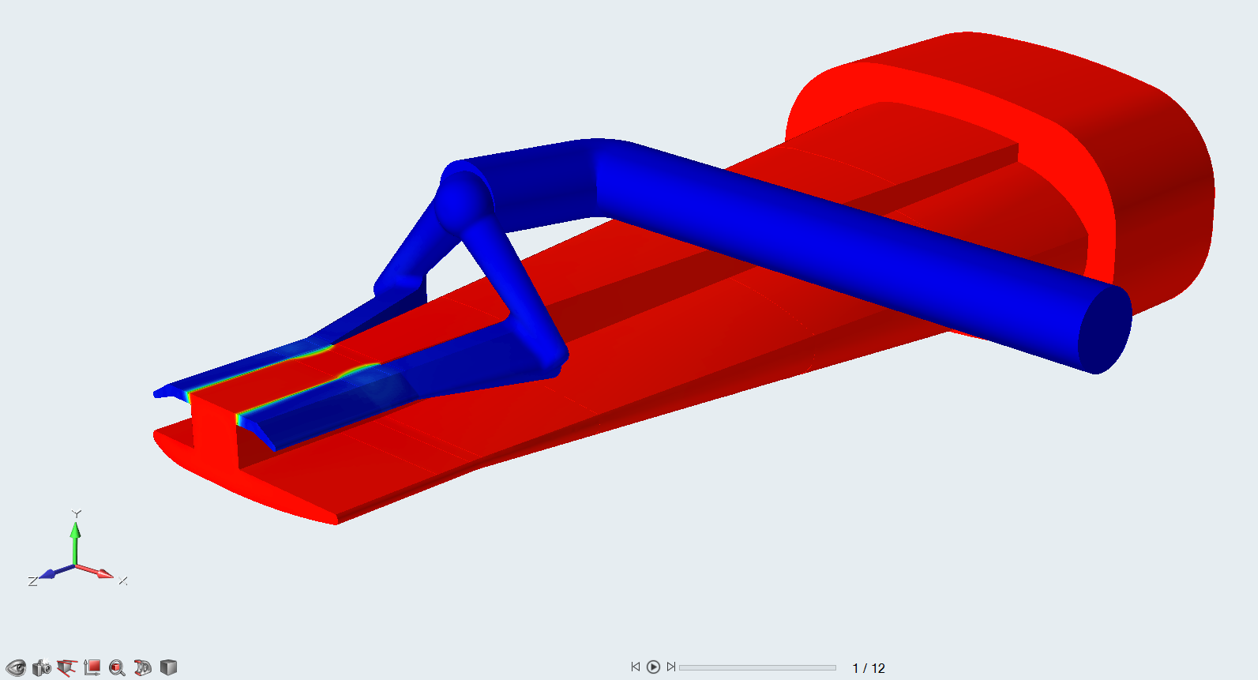

Figure 2. Velocity - Die Exit

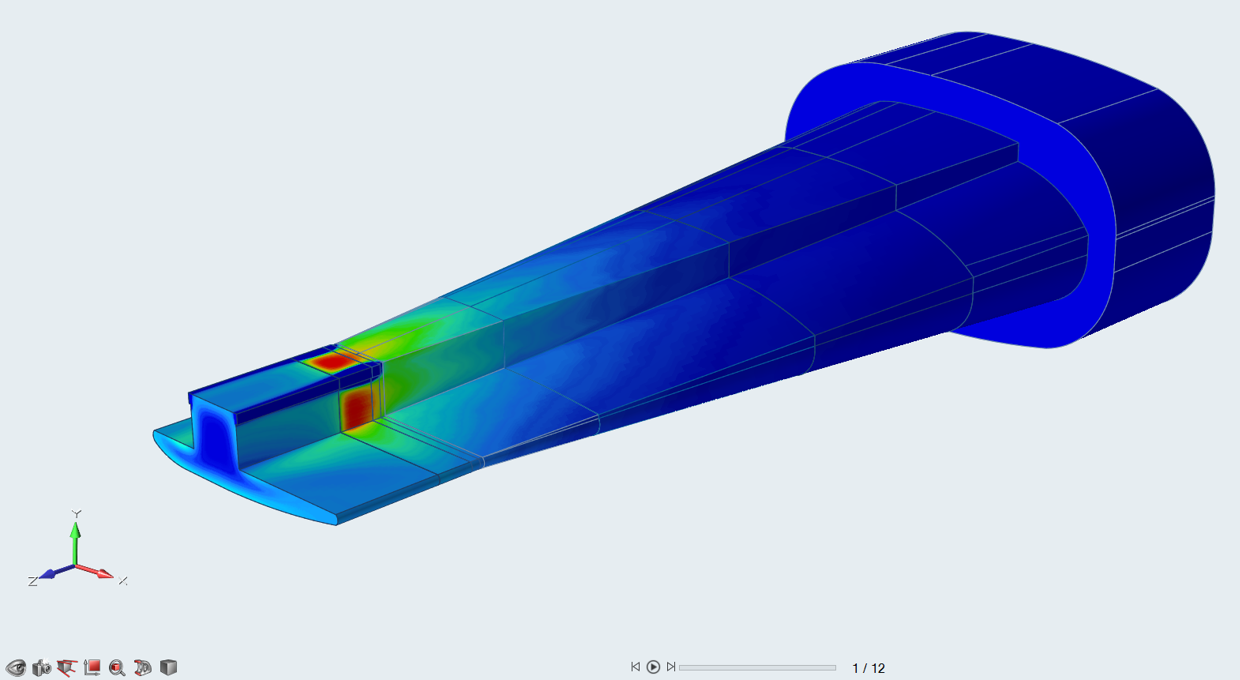

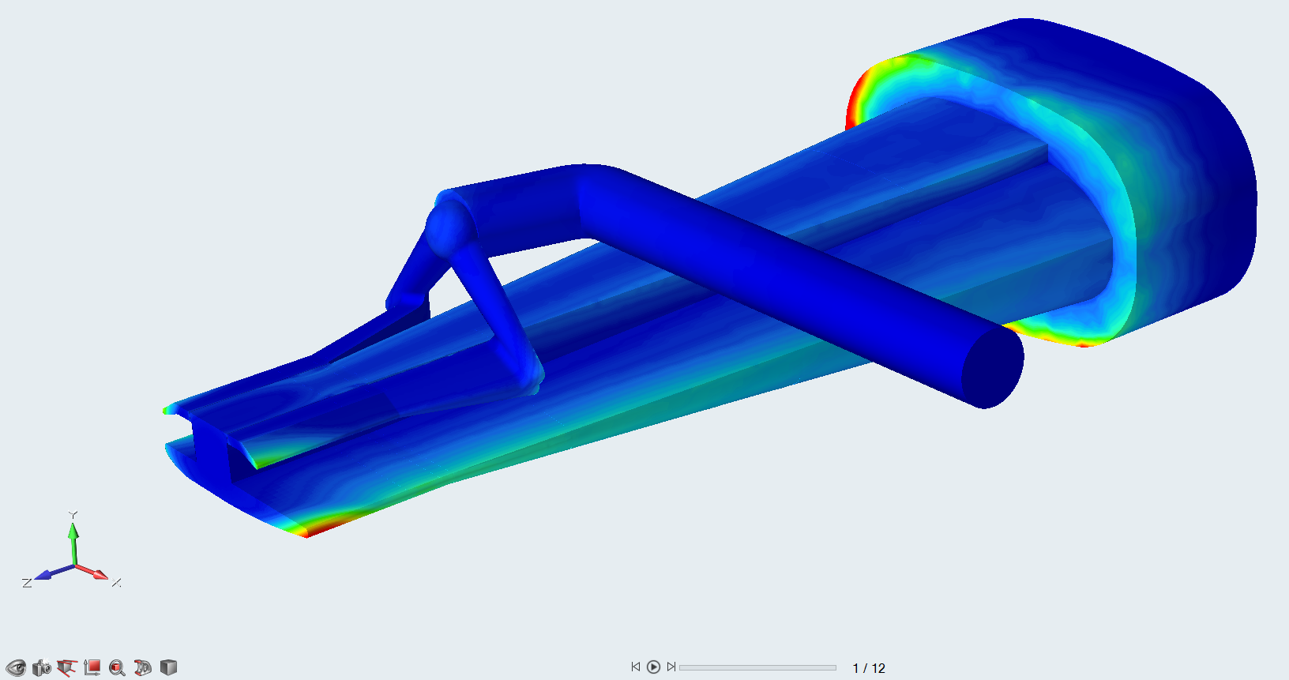

Figure 3. Deformation

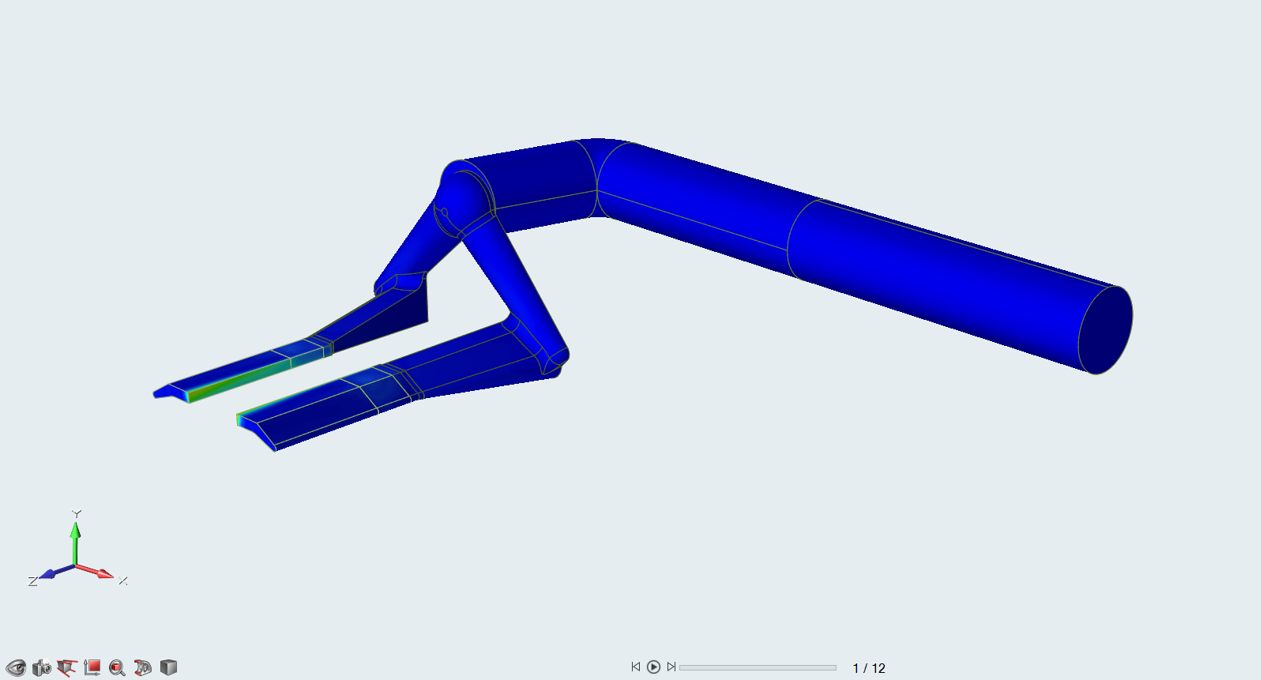

Figure 4. Pressure

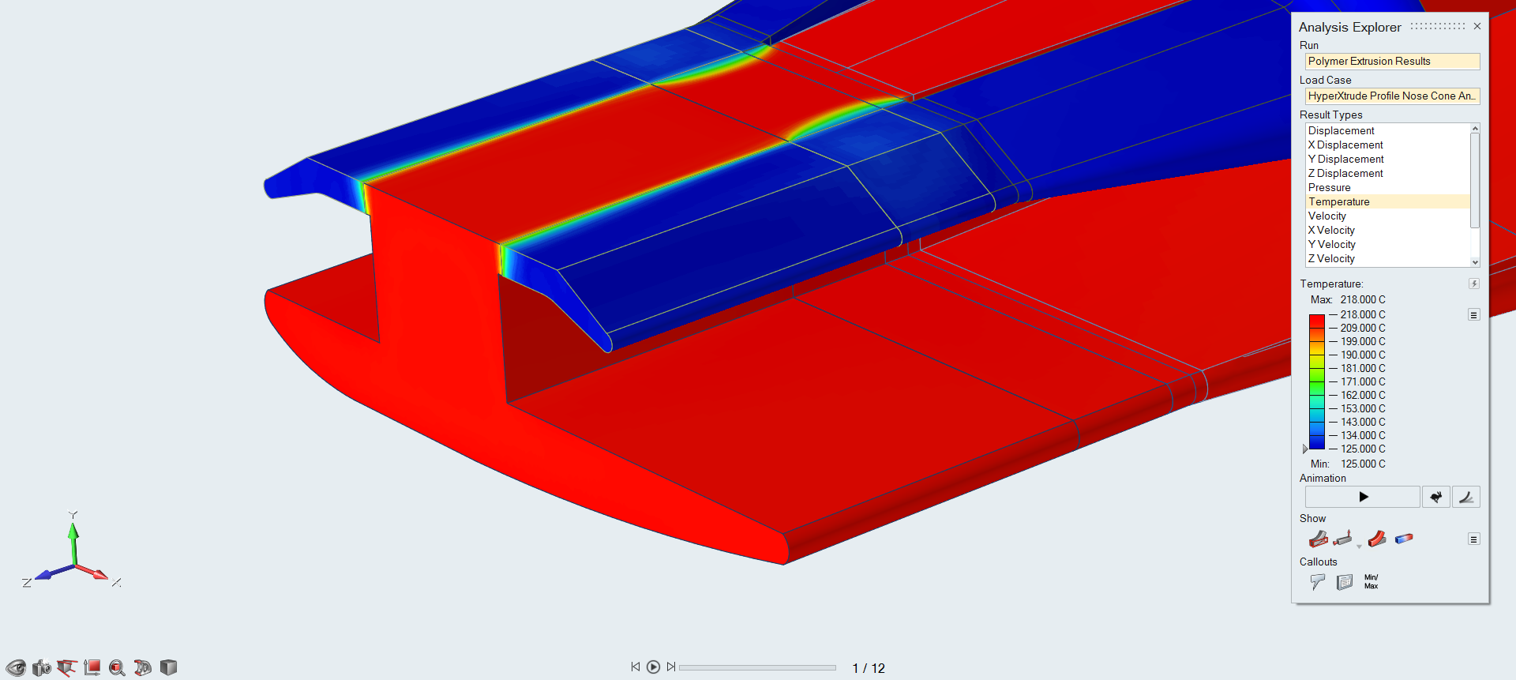

Figure 5. Temperature

Figure 6. Temperature - Polymer Layer 1

Figure 7. Temperature - Polymer Layer 2

Figure 8. Temperature - Die Exit

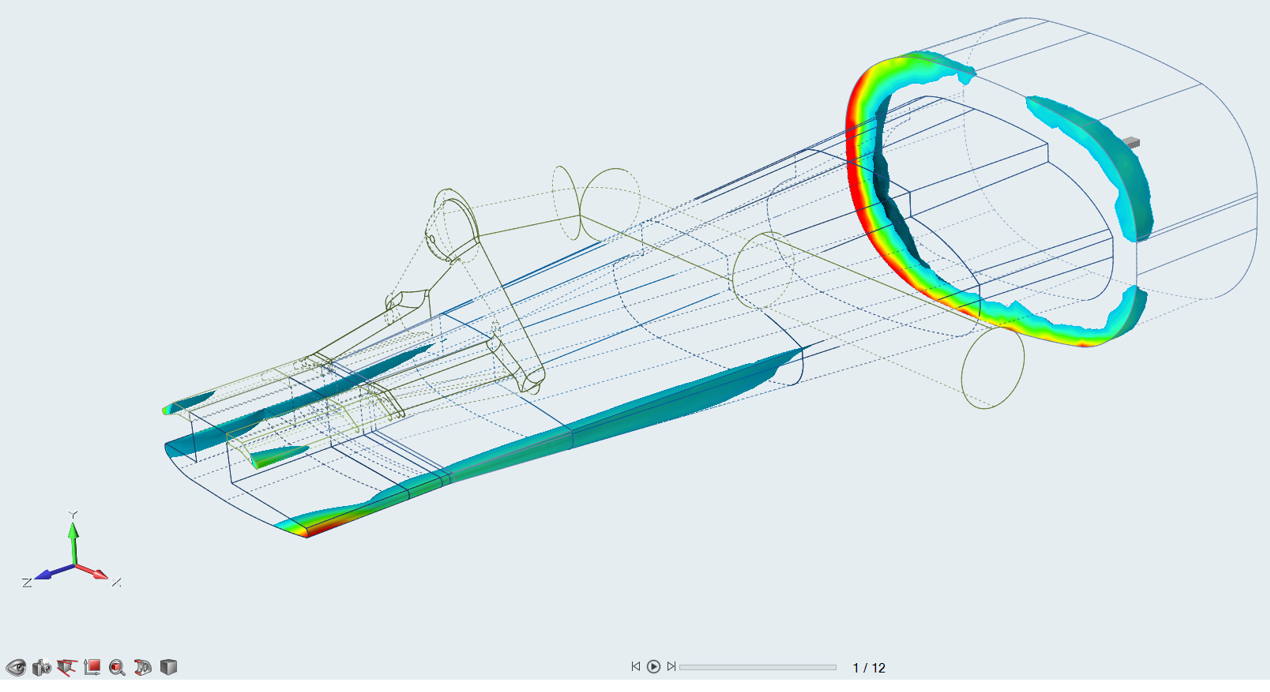

Figure 9. Strain Rate

Figure 10. Residence Time

Figure 11. Residence Time

and select the partitioning line.

and select the partitioning line.

and perform the trimming operation.

and perform the trimming operation.