Tutorial: Polymer Solid Extrusion

Learn about the Inspire Extrude Interface, set up and complete a solid profile extrusion analysis, and post-process the results for interpretation.

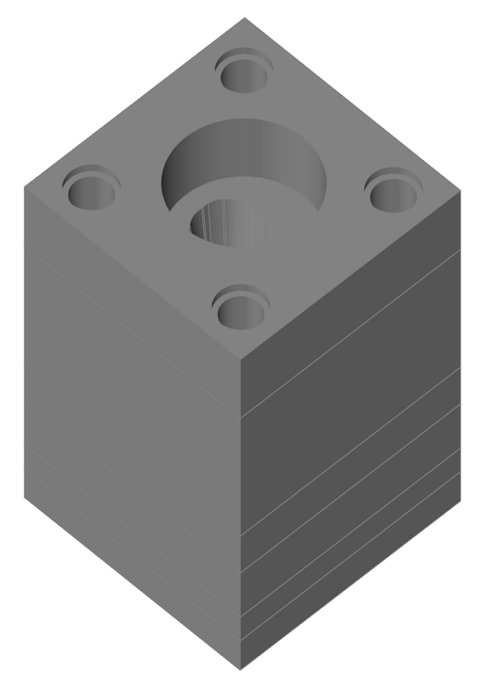

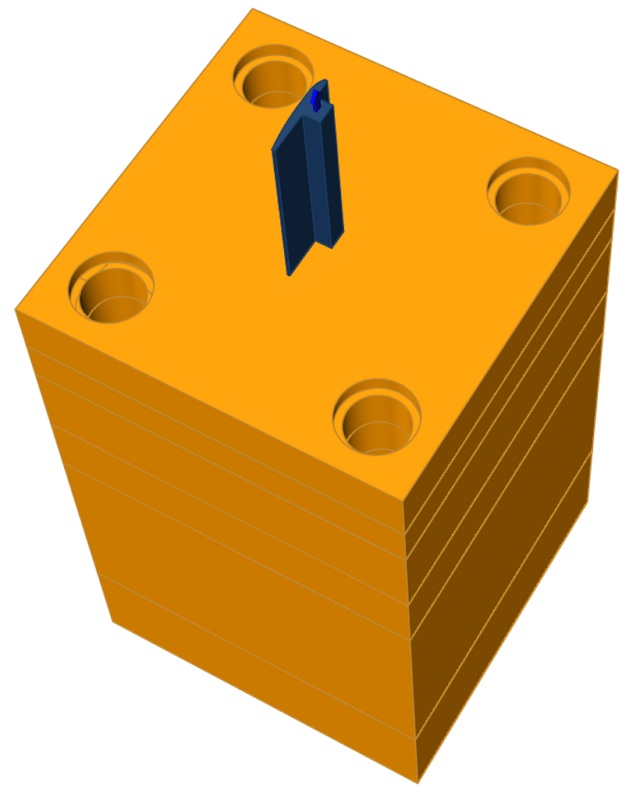

Open the Tutorial Model

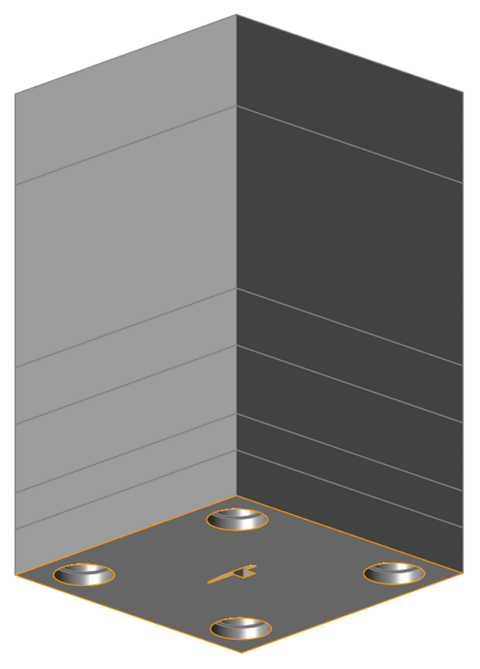

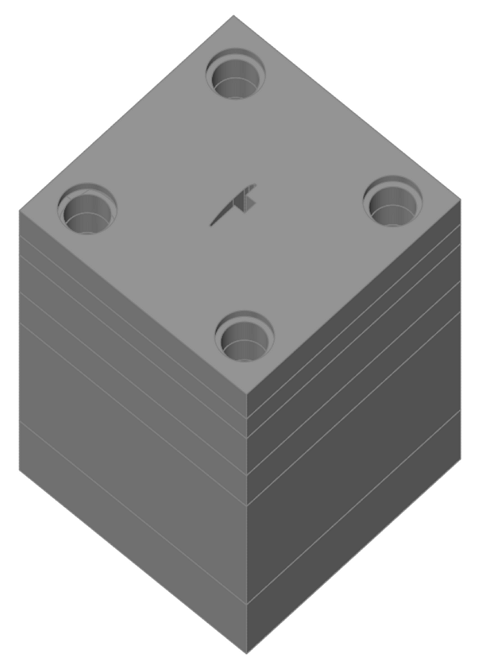

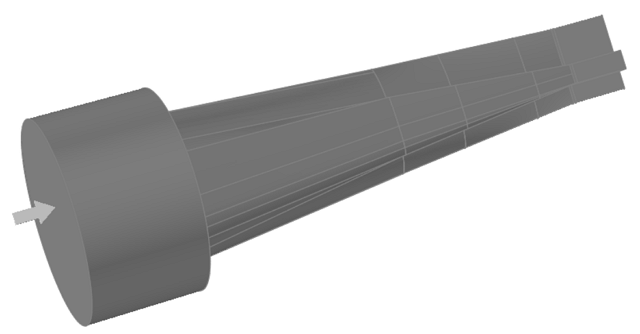

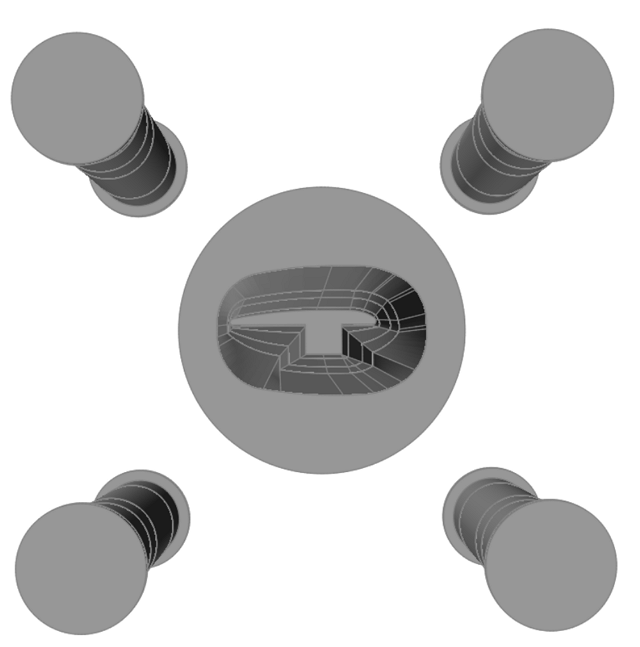

Orient the Model

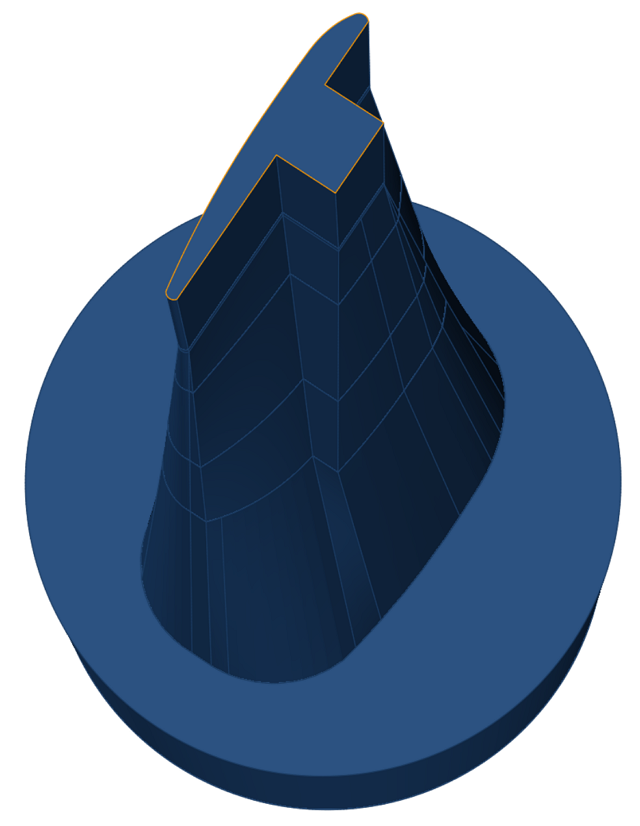

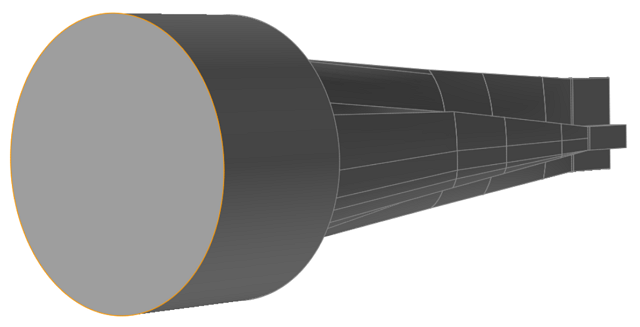

Extract Flow Volume

Delete Unwanted Solids

-

Orient the model such that selecting solids is easy.

-

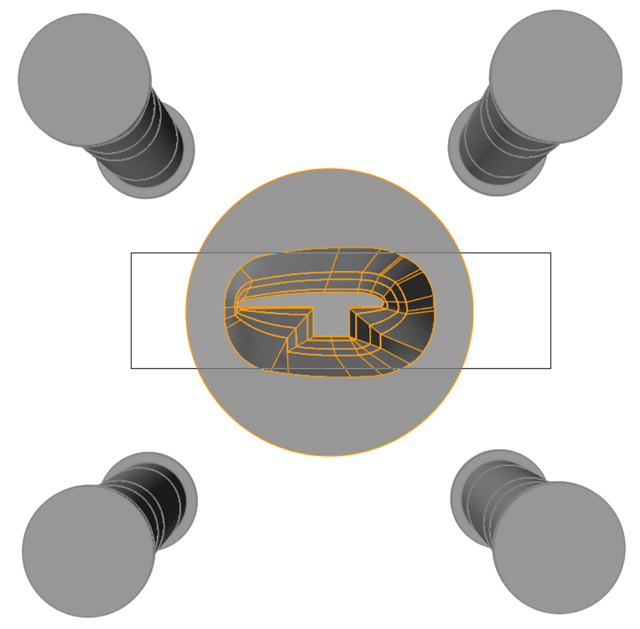

Select solids which belong to Flow Volume and hide them by pressing

H.

-

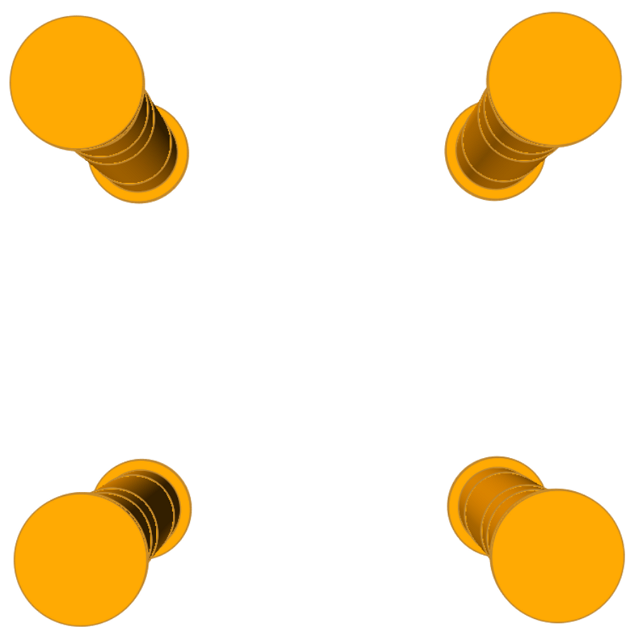

Delete the remaining solids.

- Press A to reveal the remaining solids.

-

Hold CTRL and select multiple solids on the exterior of

the model.

-

Press H to hide the selected solids.

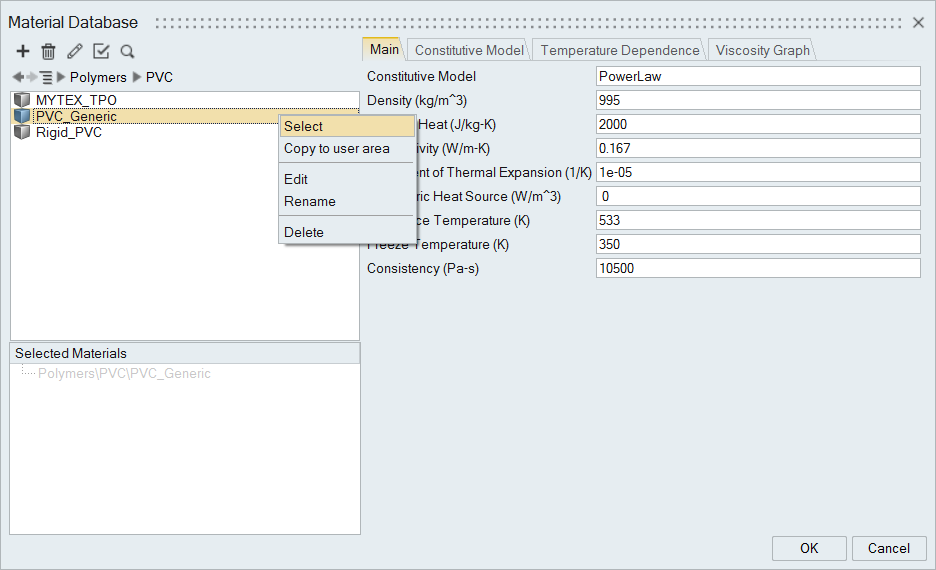

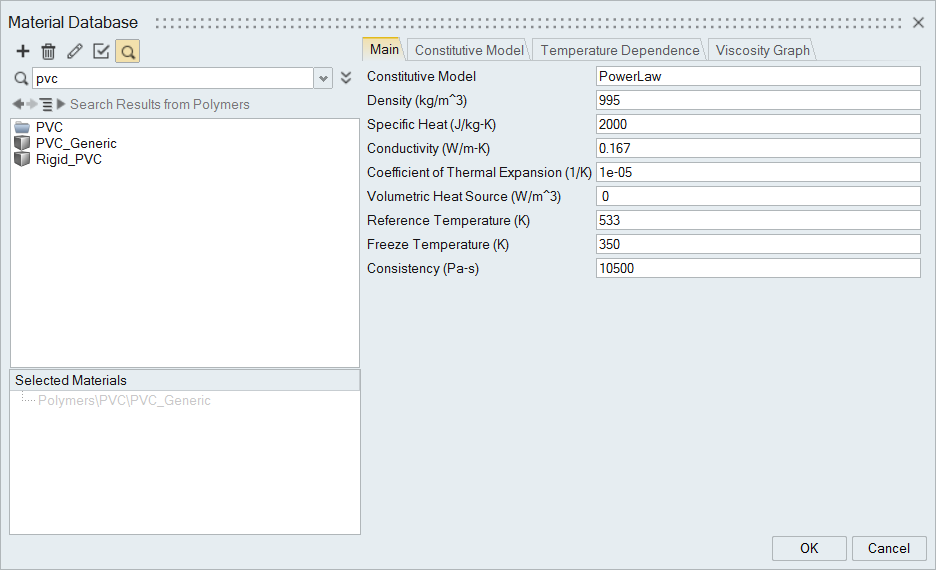

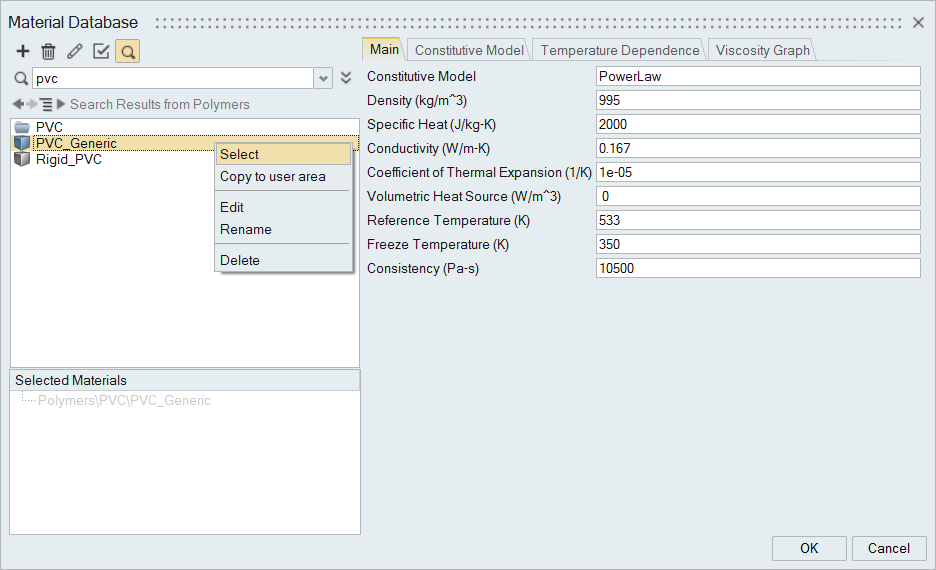

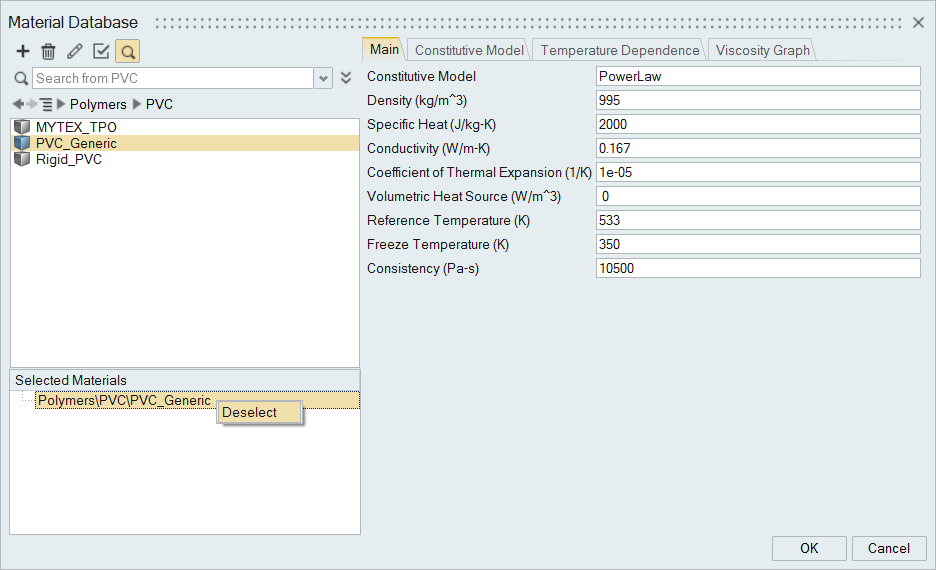

Select Materials

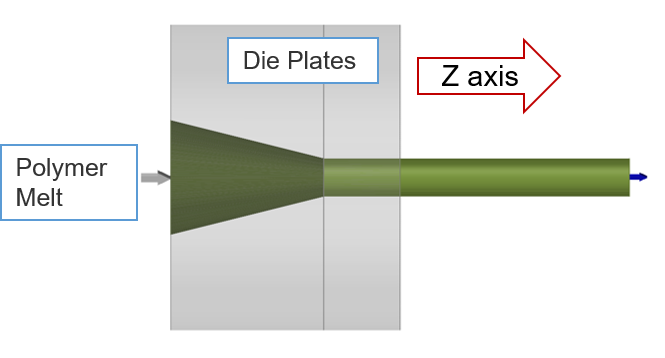

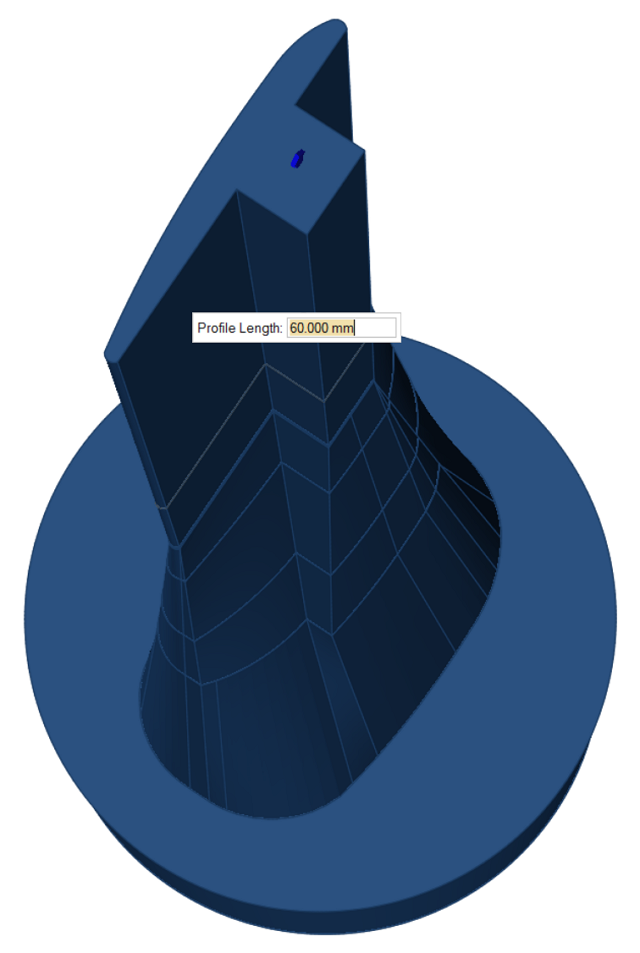

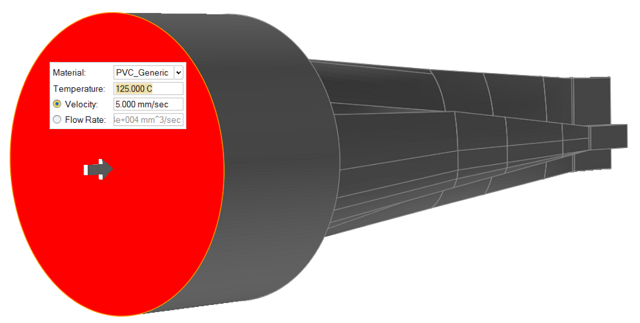

Specify Process Data - Inlet

-

Click the Inlet icon.

-

Zoom in to the inlet region of the polymer melt and select the inlet face.

-

Specify the inlet conditions.

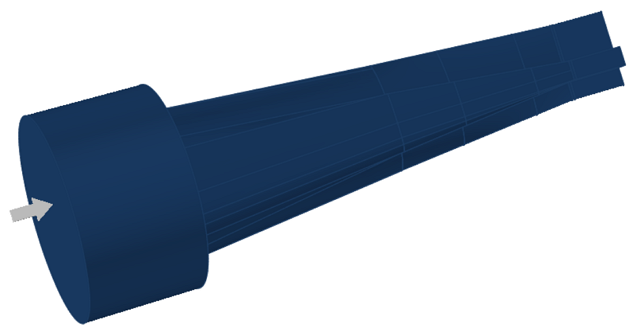

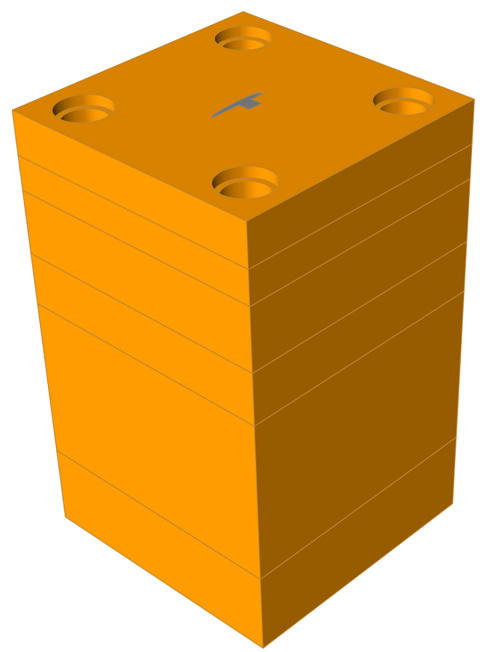

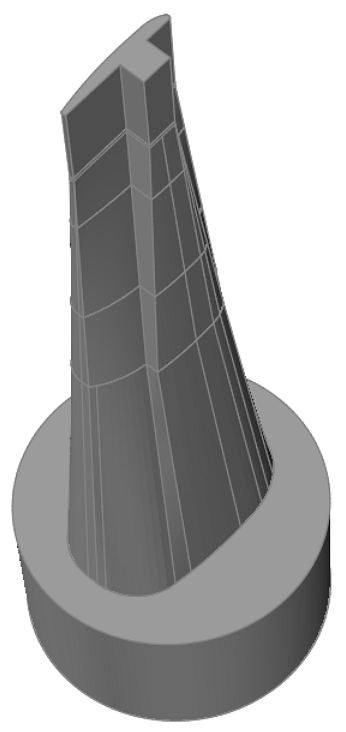

Organize Solids into Polymer Layers

Create Profile Solids

Delete Die Assembly Solids

Save the Model

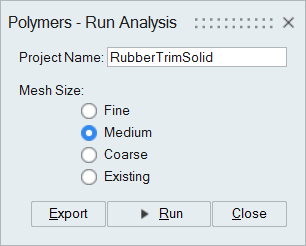

Submit the Job for Simulation

-

Click the Run Analysis icon.

-

Specify parameters for the analysis process.

- Click Run.

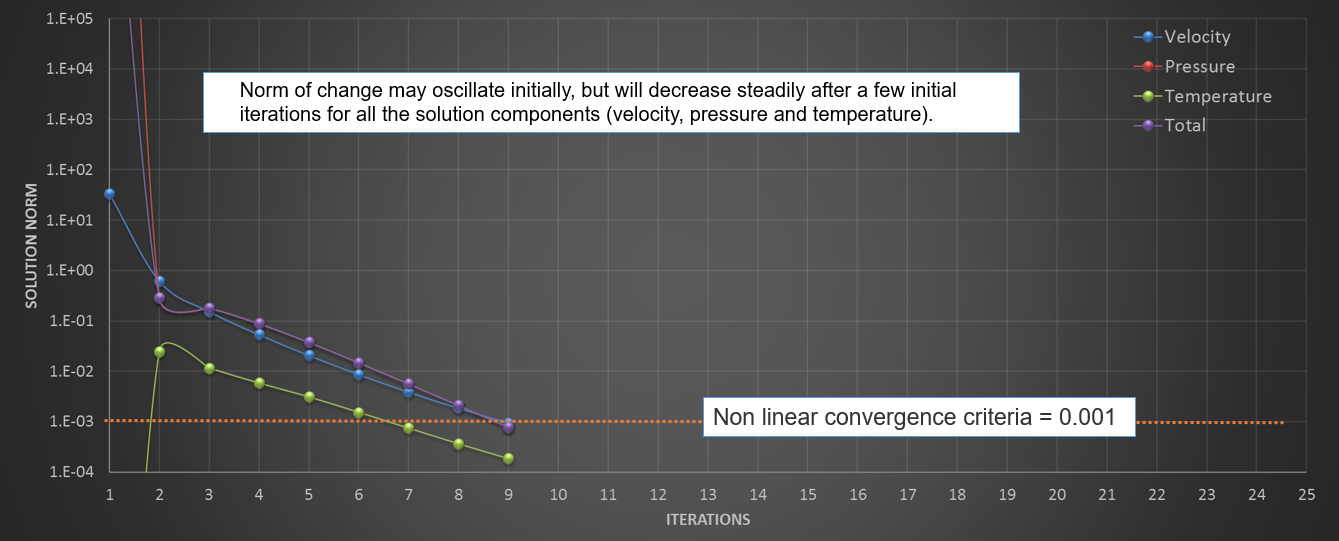

Monitor Job Status

Interpret Out File Data

- Out file: This is an ASCII file, which helps to verify the input data and gives a quick overview of the result.

- H3D File: This is a Binary file with detailed results.

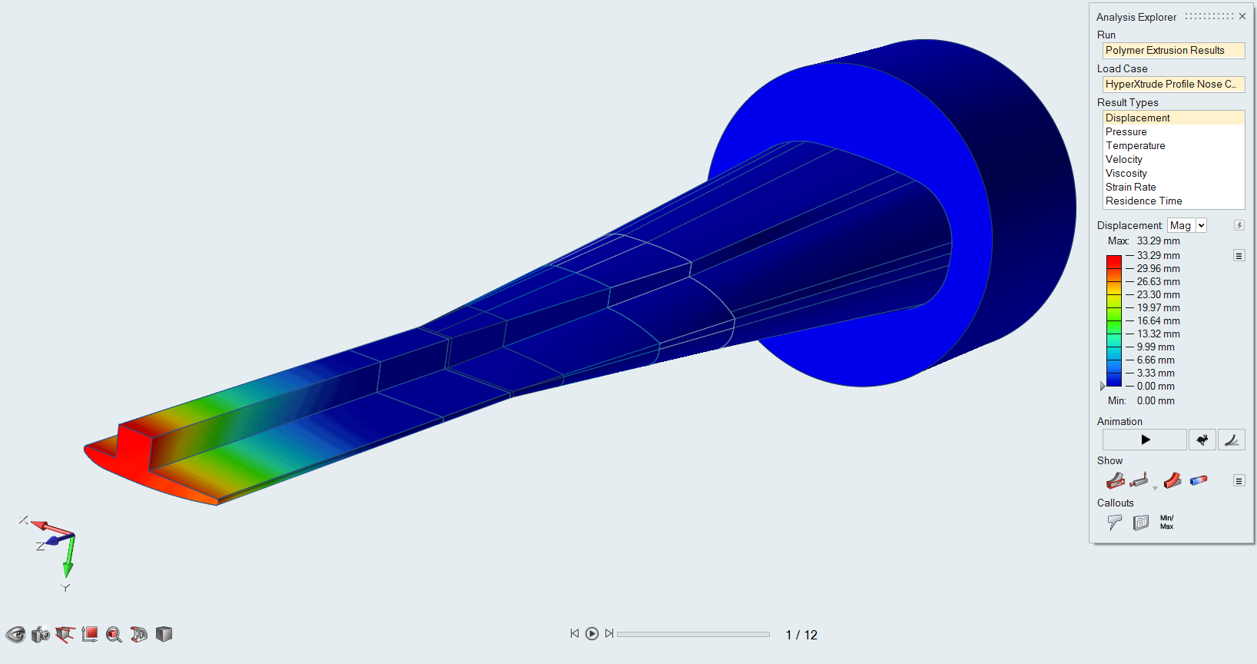

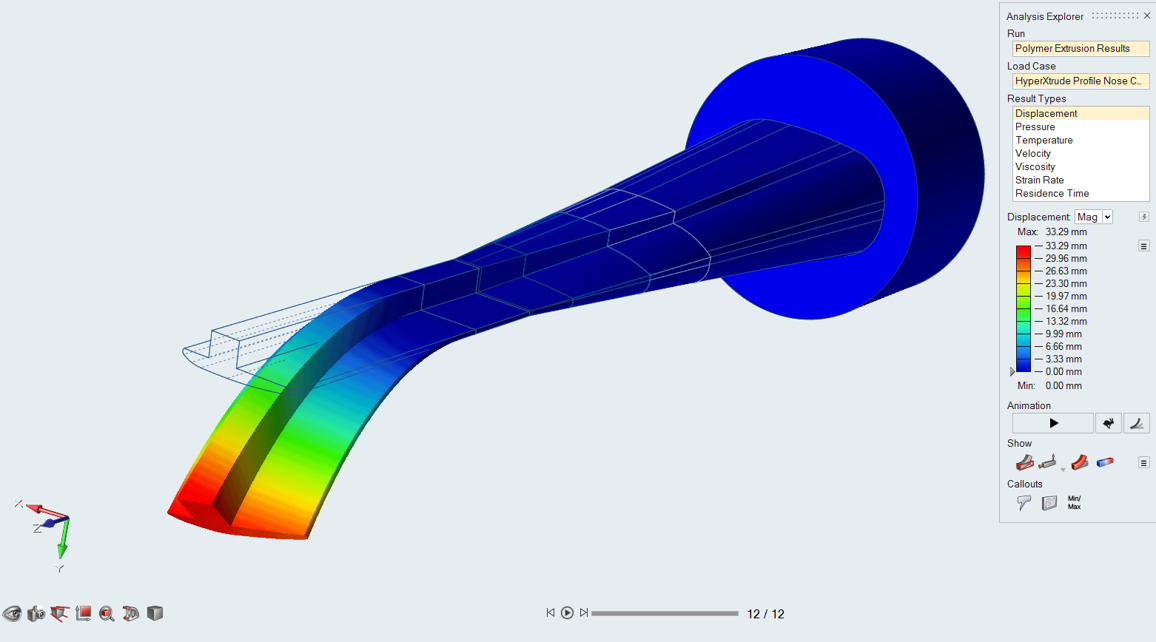

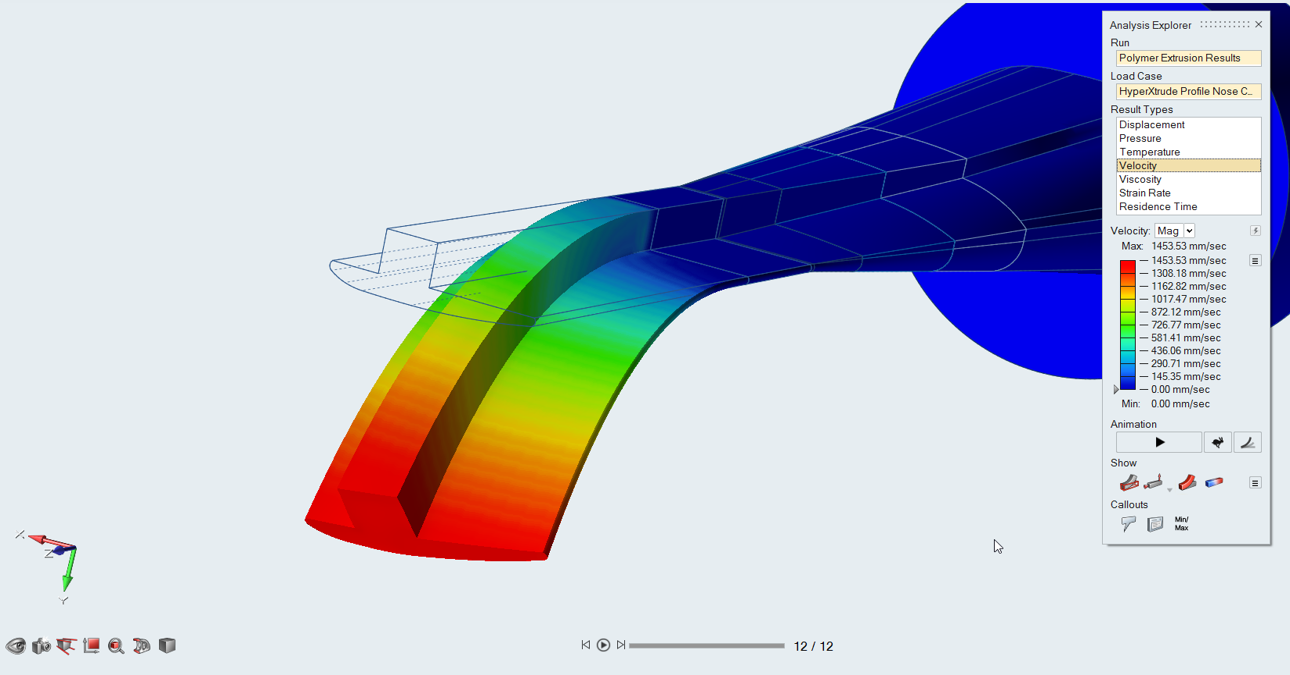

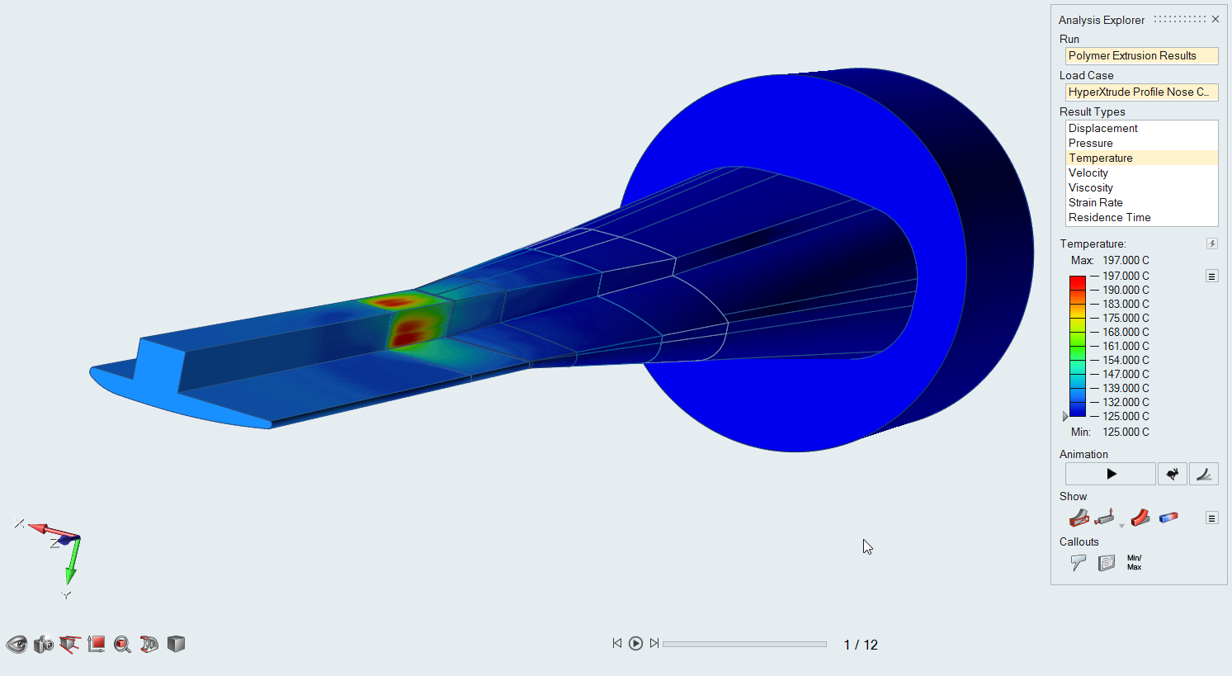

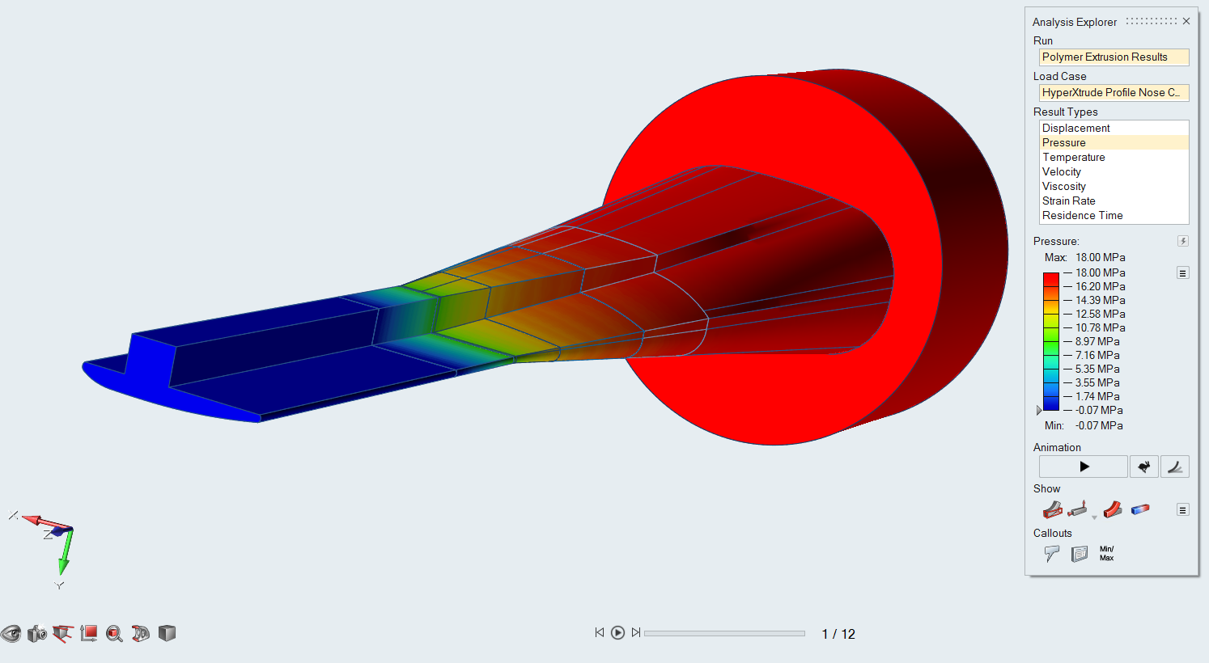

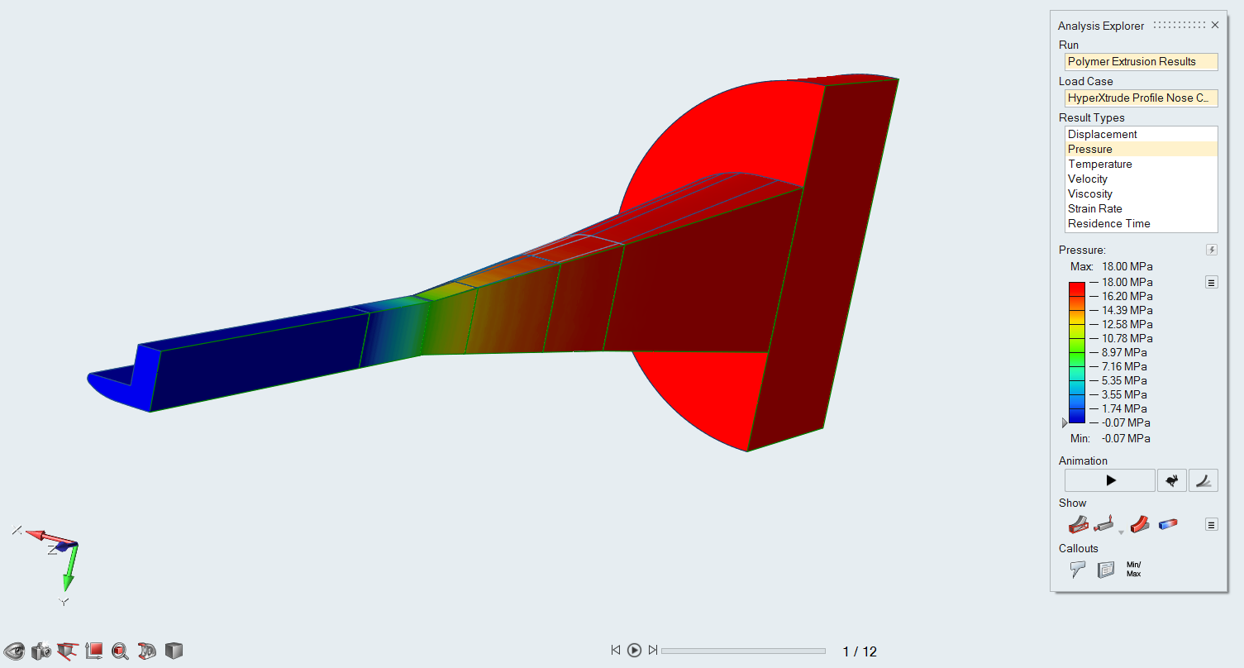

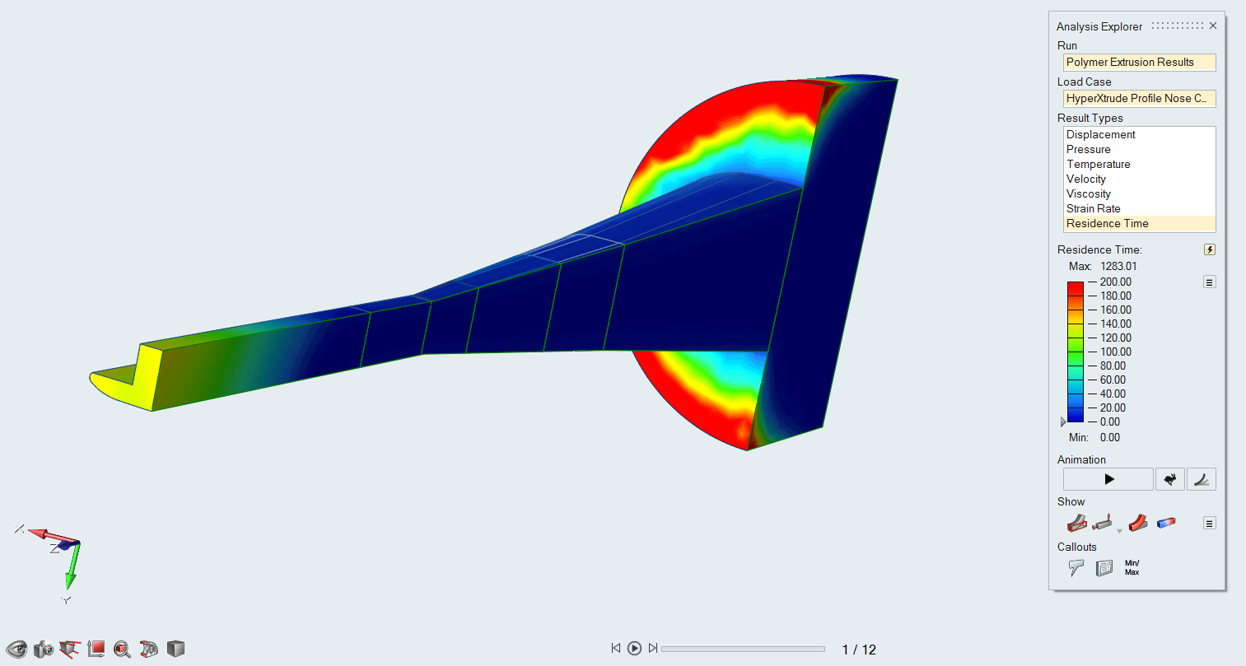

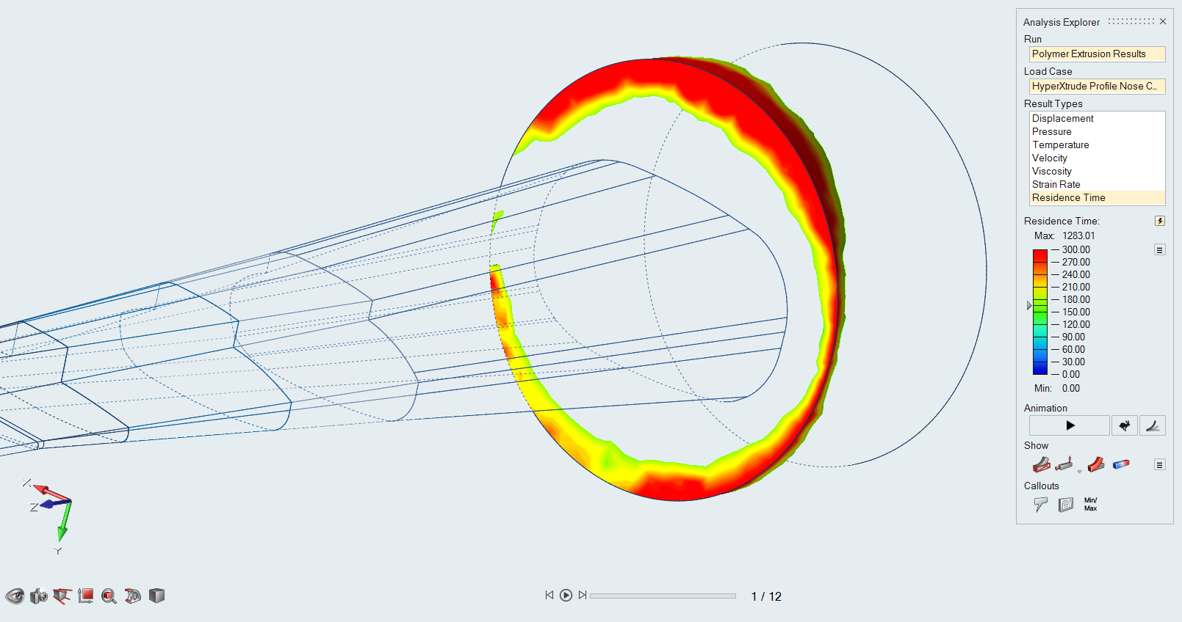

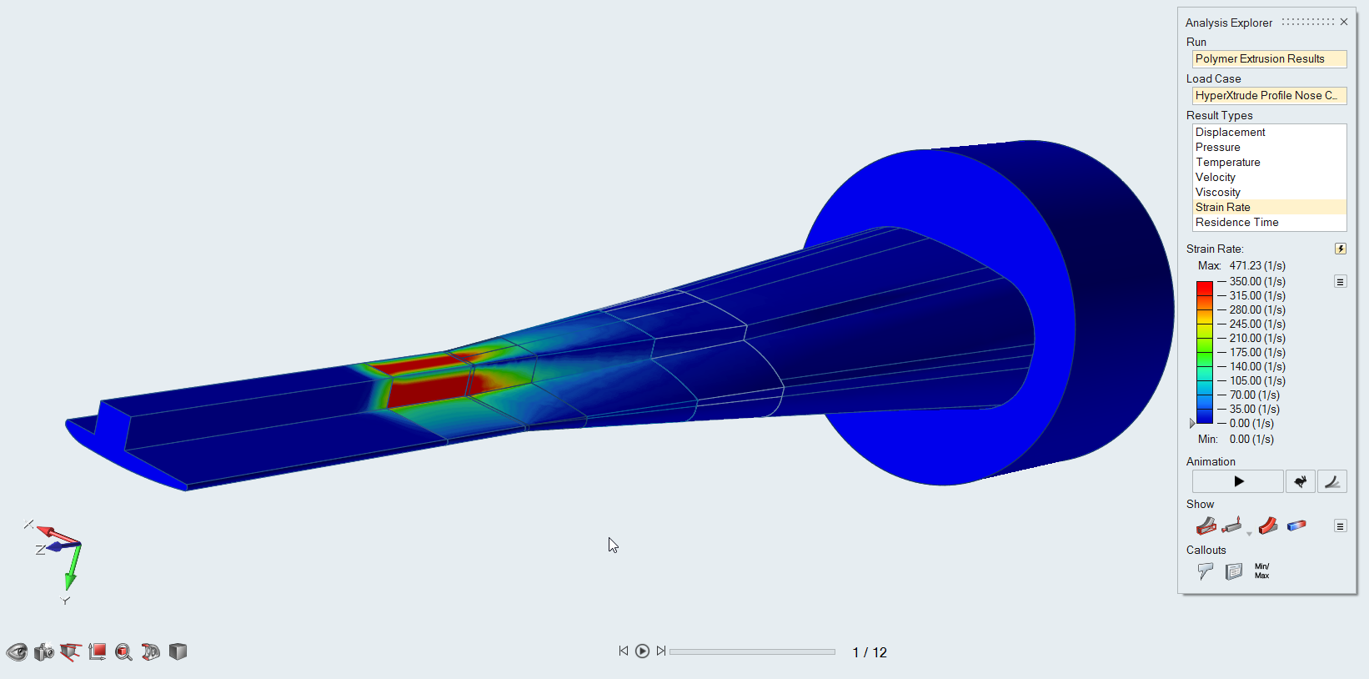

View Simulation Results