SS-T: 2030 Bushings

Create bearing loads in SimSolid.

- Purpose

- SimSolid performs meshless structural

analysis that works on full featured parts and assemblies, is tolerant of

geometric imperfections, and runs in seconds to minutes. In this tutorial,

you will do the following:

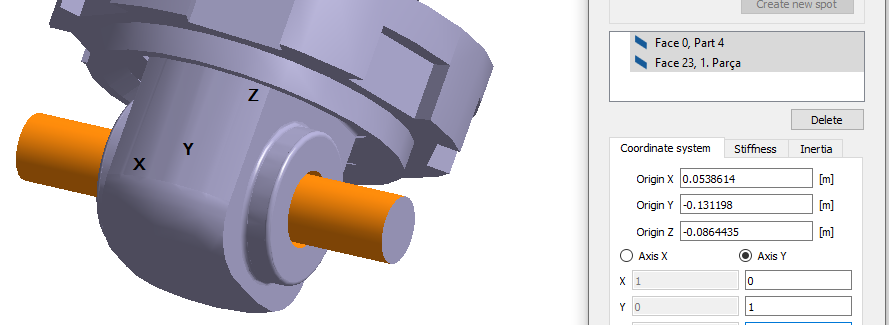

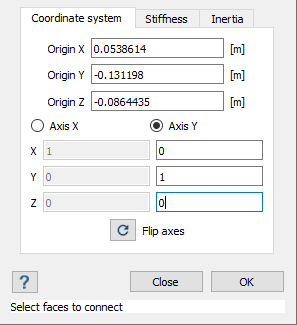

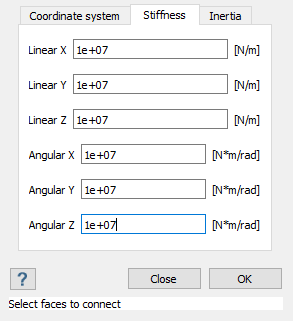

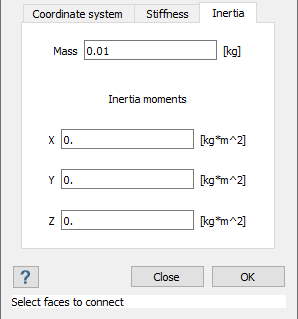

- Learn how to create bushings for a suspension assembly.

- Learn how to change the contact conditions for a specific subcase.

- Solve the modal and transient dynamic subcases and review results.

- Model Description

- The following model file is needed for this tutorial:

- Bushings.ssp

Open Project

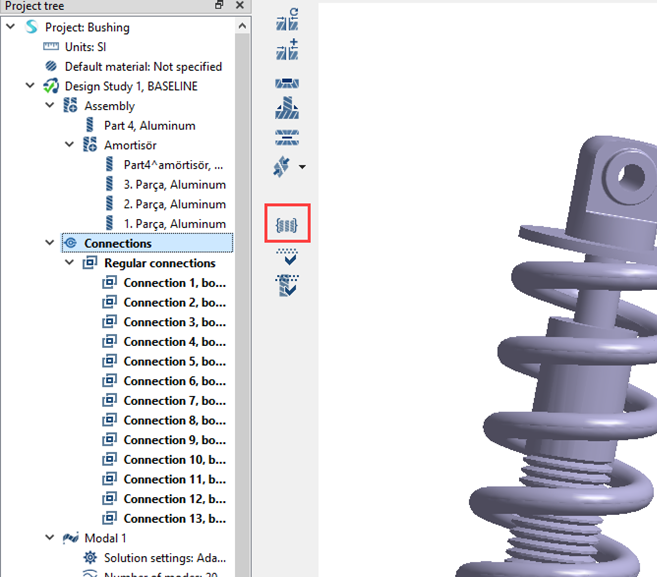

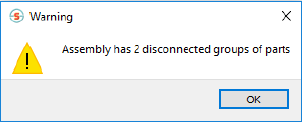

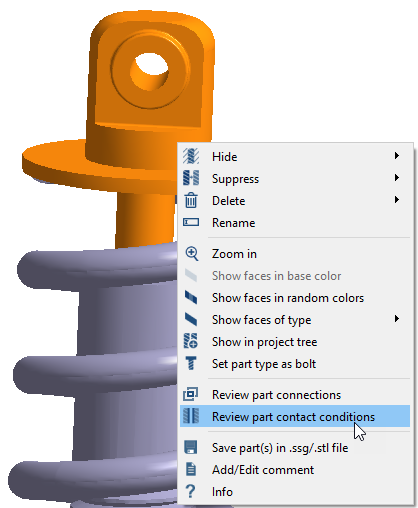

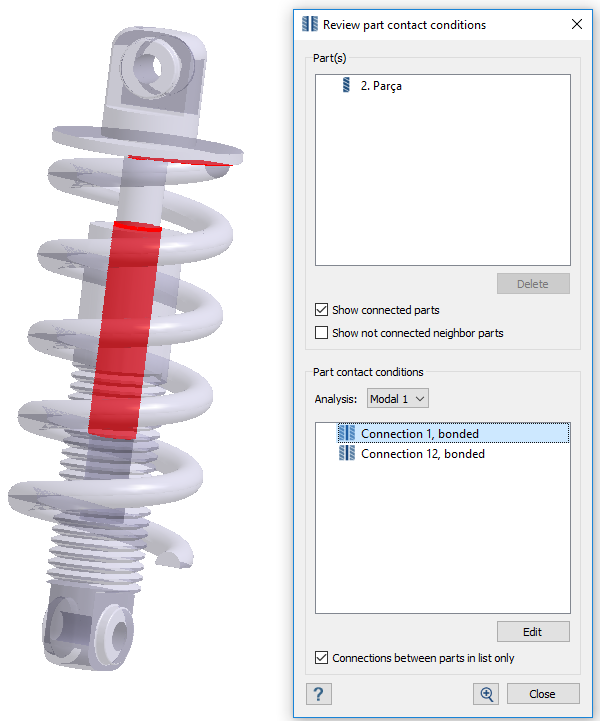

Review Connections

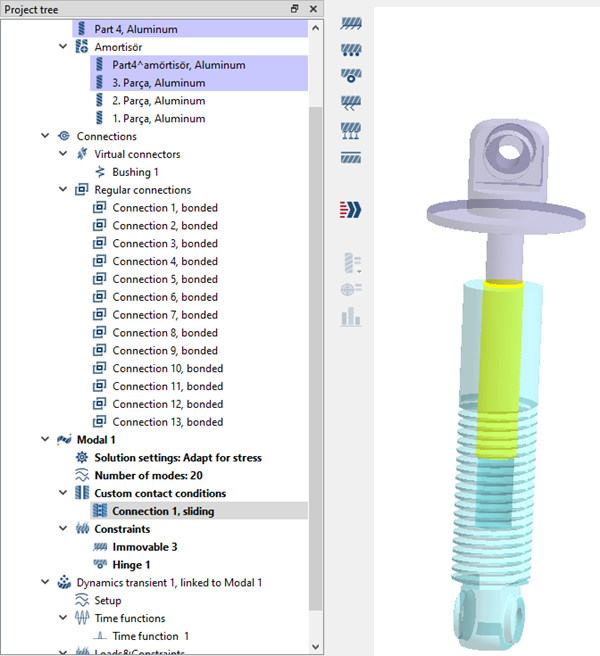

Create Bushing

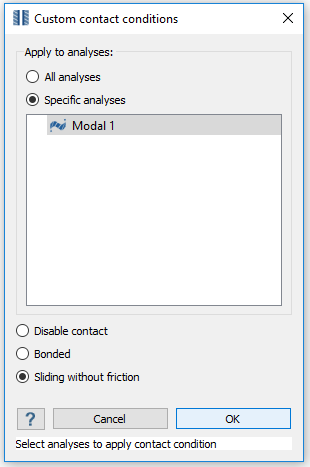

Edit Contact Conditions

Run Design Study

Solve all analyses in the design study.

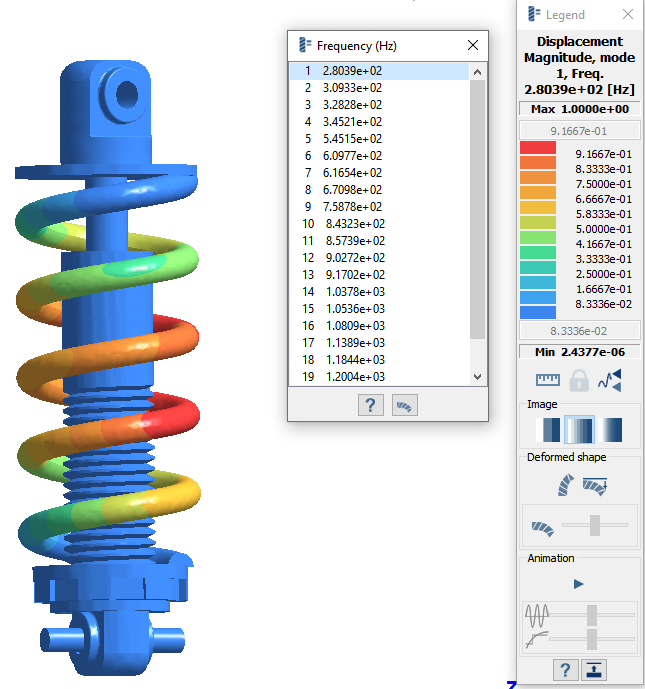

Review Modal Results

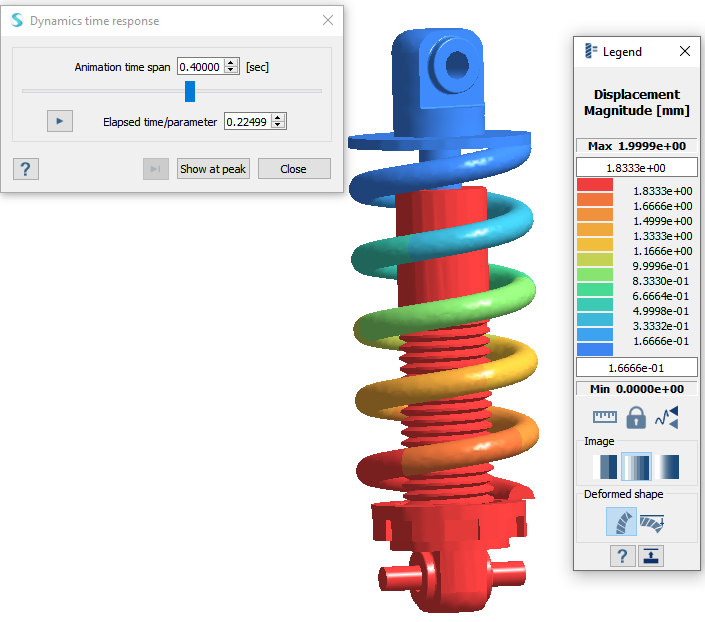

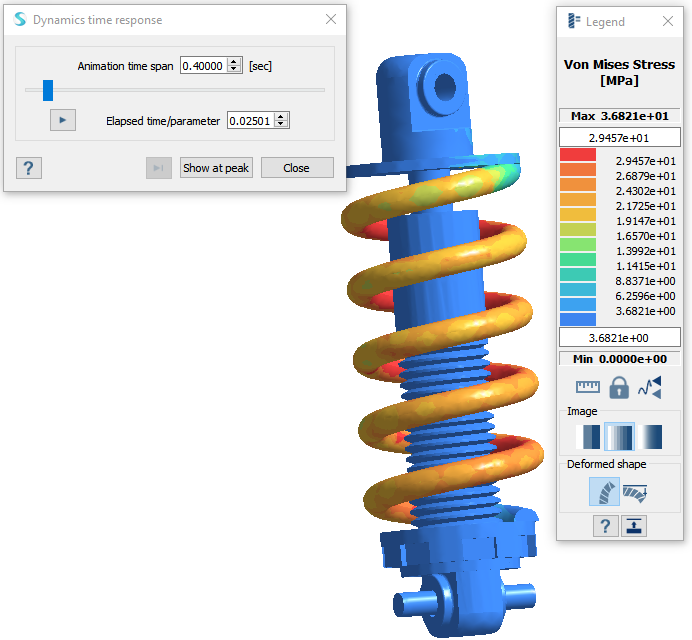

Review Dynamic Transient Results

Plot Displacement Magnitude and von Mises stress.