ACU-T: 3311 Multiphase Nucleate Boiling Using the Algebraic Eulerian Model

This tutorial provides instructions for modeling a two-phase nucleate boiling in a pipe using the Algebraic Eulerian model. Prior to starting this tutorial, you should have already run through the introductory HyperWorks tutorial, ACU-T: 1000 HyperWorks UI Introduction, and have a basic understanding of HyperWorks CFD and AcuSolve. To run this simulation, you will need access to a licensed version of HyperWorks CFD and AcuSolve.

Problem Description

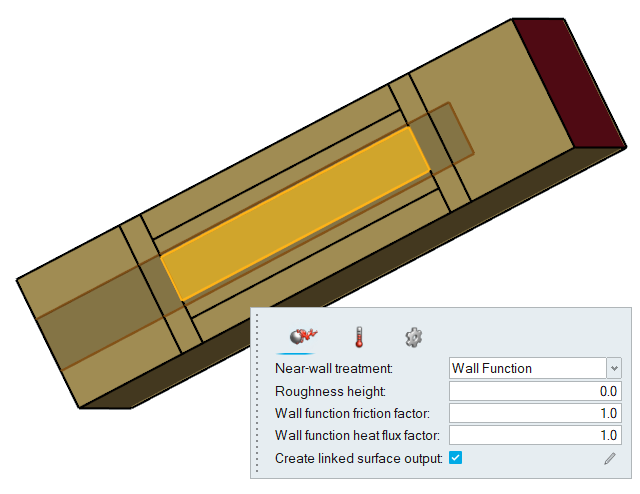

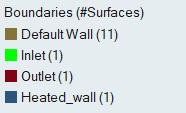

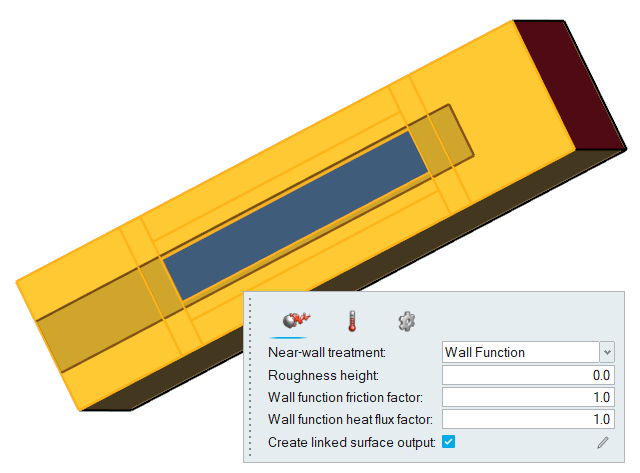

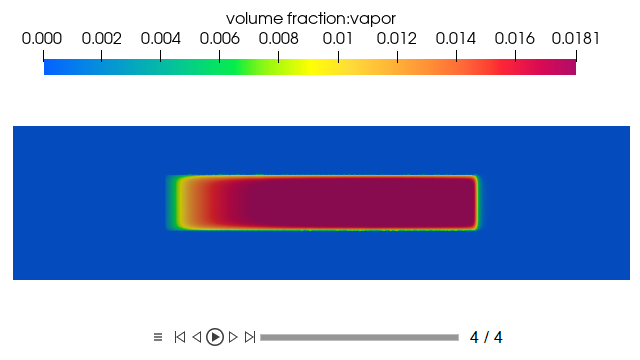

The problem to be addressed in this tutorial is shown schematically in Figure 1. It consists of a channel with a heated wall at the bottom. The temperature of the wall is selected to onset the nucleate boiling at the heated wall.

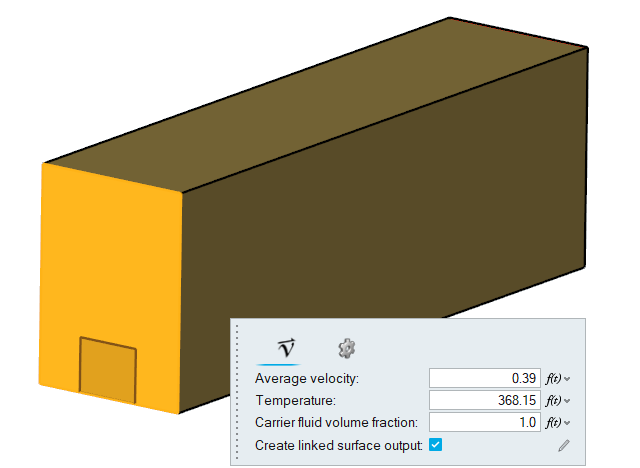

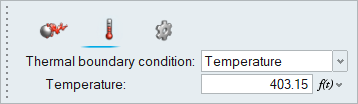

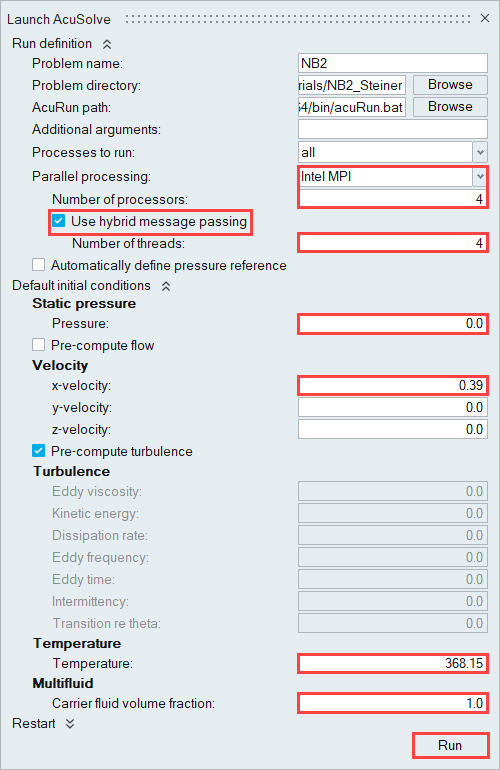

Water at 2 bar pressure and 95 ℃ temperature enters the inlet at an average velocity of 0.39 m/sec and passes through the heated wall which is maintained at 130 ℃.

The pre-heated air enters the inlets and heat is transferred to the fluid from the walls. The heat causes sub-cooled boiling to occur in the region close to the wall and leads to formation of bubbles at nucleation sites.

The heat transfer in this regime is basically dominated by two effects, the macro convection due to the motion of the bulk liquid and the latent heat transport associated with the evaporation of the liquid micro-layer between the bubble and the heated wall.

Figure 1. Schematic of Channel

Start HyperWorks CFD and Open the HyperMesh Database

Validate the Geometry

The Validate tool scans through the entire model, performs checks on the surfaces and solids, and flags any defects in the geometry, such as free edges, closed shells, intersections, duplicates, and slivers.

Figure 3.

Set Up Flow

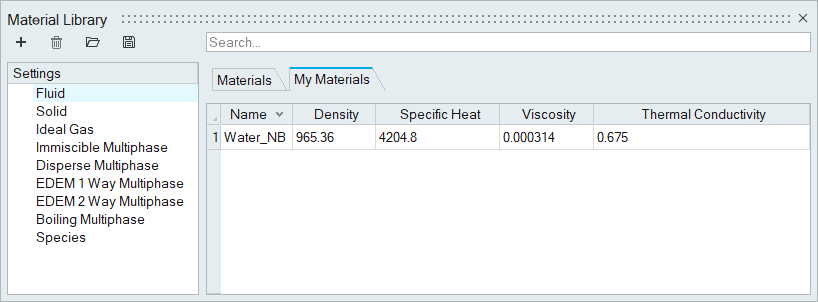

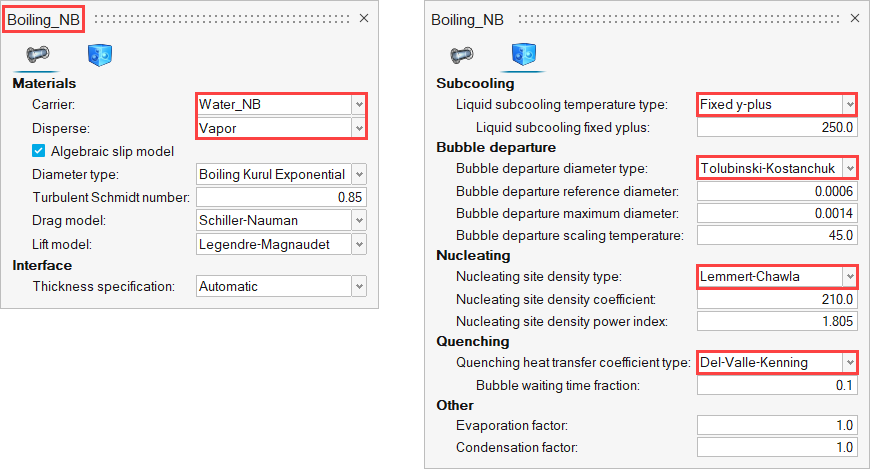

Verify and Create Materials

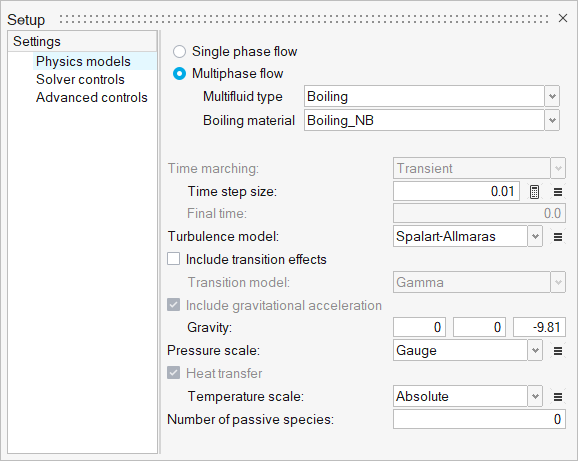

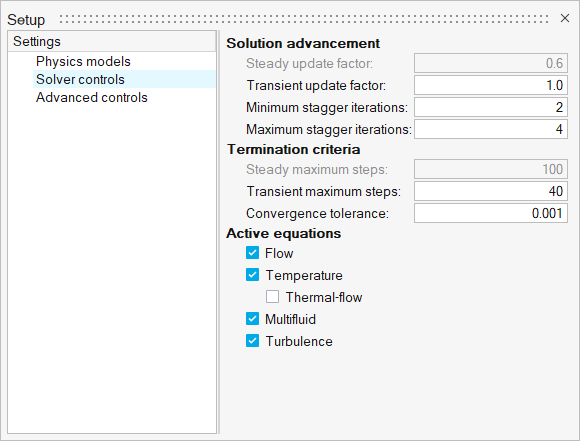

Set the General Simulation Parameters

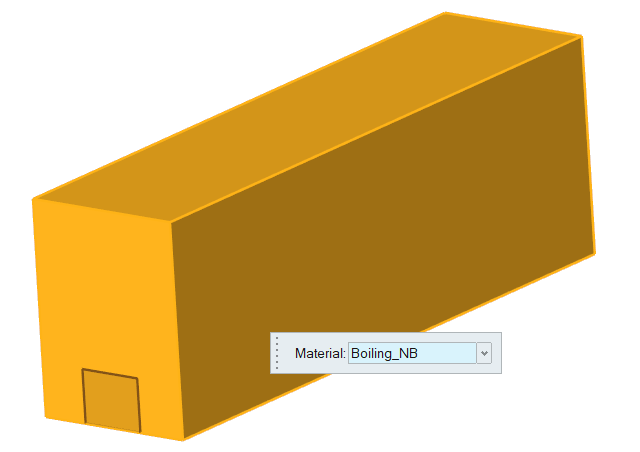

Assign Material Properties

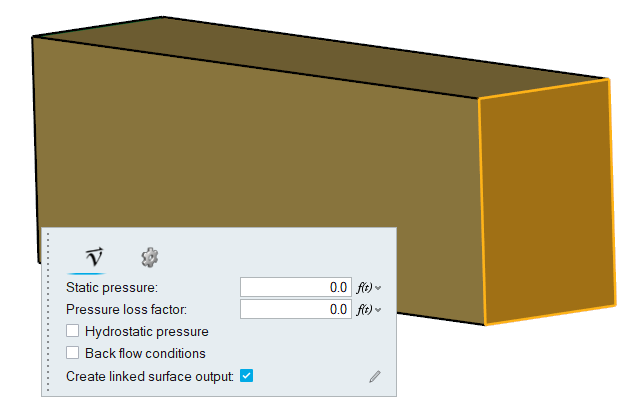

Define Flow Boundary Conditions

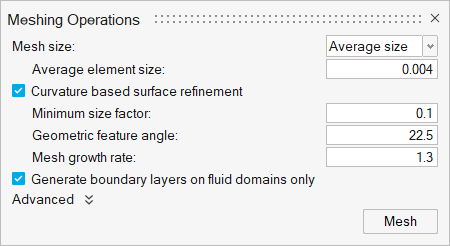

Generate the Mesh

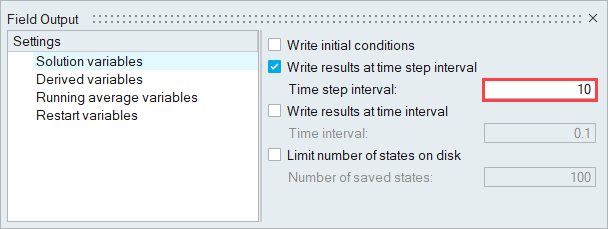

Run AcuSolve

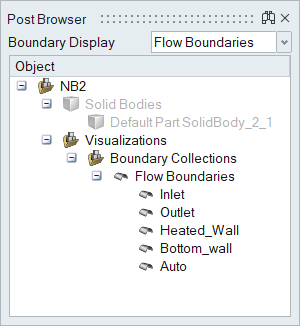

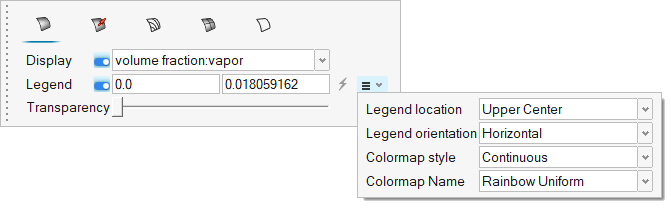

Post-Process the Results with HW-CFD Post

Summary

In this tutorial, you successfully learned how to set up and solve a simulation involving a two-phase nucleate boiling using HyperWorks CFD. You started by opening the HyperMesh input file with the geometry and then defined the simulation parameters and flow boundary conditions. Once the solution was computed, you used HyperWorks CFD Post to create the contours of volume fraction of vapor.