OptiStruct Connector Types

Supported OptiStruct connector types and property scripts.

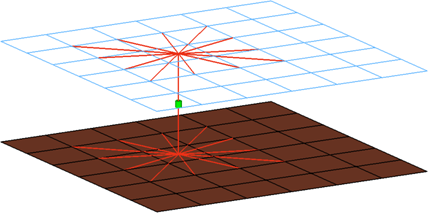

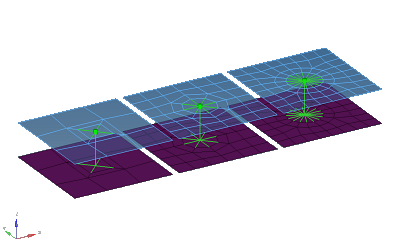

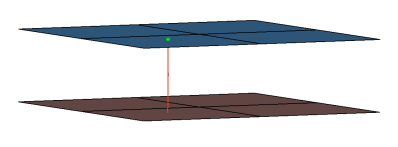

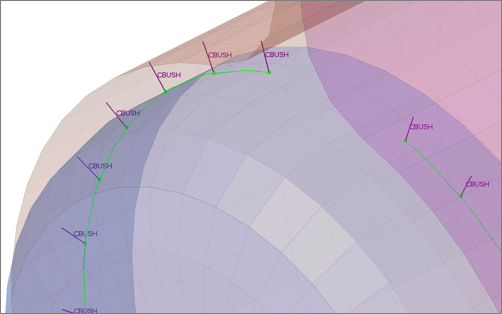

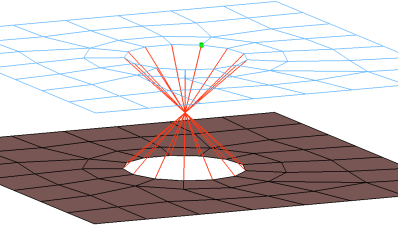

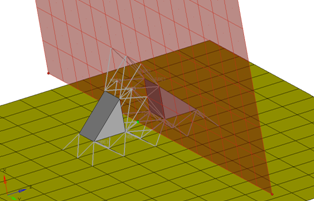

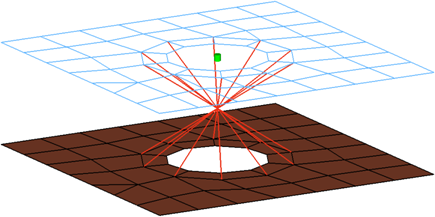

- OptiStruct Sealing

- Creates RBE3 elements for the head and CBUSH element for the body. The head elements

project and connect to the nodes of the adjoining shell elements.

Figure 1.CFG optistruct 5 sealing *filter spot *head rbe3 1 0 *body 0 spring 6 1 cfg_optistruct_5_sealing - OptiStruct bush

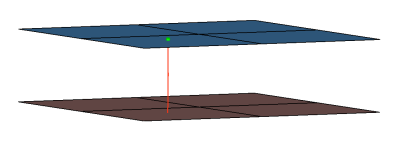

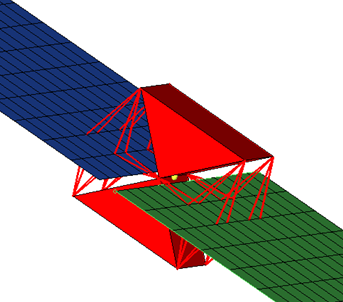

- Creates RBE2 elements for the head and CBUSH element for the body. The head elements

project and connect to the nodes of the adjoining shell elements.

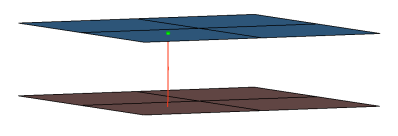

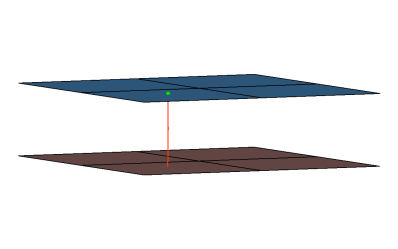

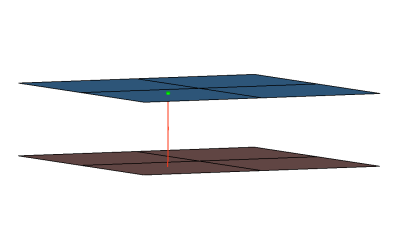

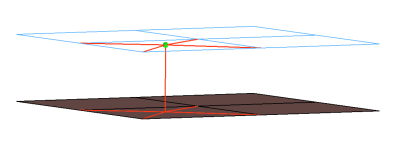

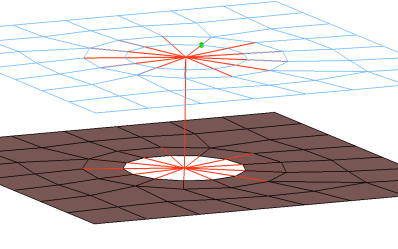

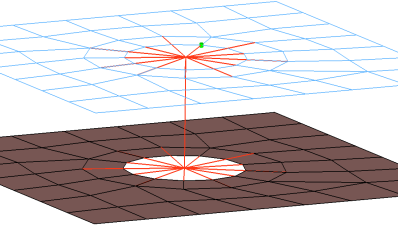

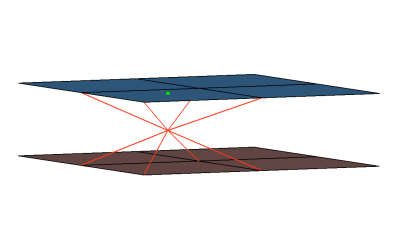

Figure 2.CFG optistruct 6 bush *filter spot *head rigidlink 1 1 *body 0 spring 6 1 cfg_optistruct_6_bush - OptiStruct rbe3 (load transfer)

- Creates RBE3 elements for the body. The degrees of freedom are constrained in the

x, y, z for the dependant nodes.

Figure 3.CFG optistruct 31 rbe3 (load transfer) *filter spot *style mpc 1 *head *body 0 rbe3 1 1 dofs=123 - OptiStruct clip

- Creates a single RBE2 element for the body. The element projects and connects to the nodes

of the adjoining shell elements which form the hole and also the nodes which form the

washer layer. The connector location can either be on the edge of the hole, center of

the hole, midpoint in between the two holes or on the second row of nodes which form

the washer layer.

Figure 4.CFG optistruct 50 clip *filter bolt *style bolt 1 *head *body 0 rigidlink 1 2 - OptiStruct bolt (washer 1) cbar

- Creates RBE2 elements for the head and CBAR element for the body. The head elements

project and connect to the nodes of the adjoining shell elements which form the hole

and also the second row of nodes which form the washer layer. The connector location

can either be on the edge of the hole, center of the hole, midpoint in between the two

holes or on the second row of nodes which form the washer layer.

Figure 5.CFG optistruct 51 bolt (washer 1) cbar *filter bolt *style bolt 0 *head rigidlink 1 12 *body 0 bar2 1 1 - OptiStruct bolt (general)

- Creates RBE2 elements for the head and the body. The head elements project and connect to

the nodes of the adjoining shell elements which form the hole. The connector location

can either be on the edge of the hole, center of the hole, midpoint in between the two

holes or on the second row of nodes which form the washer layer.

Figure 6.CFG optistruct 52 bolt (general) *filter bolt *style bolt 0 *head rigidlink 1 1 *body 0 rigid 1 1 - OptiStruct bolt (CBAR)

- Creates RBE2 elements for the head and CBAR element for the body. The head elements

project and connect to the nodes of the adjoining shell elements which form the hole.

The connector location can either be on the edge of the hole, center of the hole,

midpoint in between the two holes or on the second row of nodes which form the washer

layer.

Figure 7.CFG optistruct 53 bolt (CBAR) *filter bolt *style bolt 0 *head rigid 1 1 *body 0 bar2 1 1 cfg_optistruct_53_bolt - OptiStruct bolt (spider)

- Creates a many individual RBE2 elements. The element projects and connect to the nodes of

the adjoining shell elements which form the hole, the RBE2 elements are joined at the

midpoint of the bolted connection. The connector location can either be on the edge of

the hole, center of the hole, midpoint in between the two holes or on the second row

of nodes which form the washer layer.

Figure 8.CFG optistruct 54 bolt (spider) *filter bolt *style bolt 1 *head *body 0 rigid 1 1 cfg_optistruct_54_bolt - OptiStruct bolt (washer 2)

- Creates RBE2 elements for the head and the body. There are two individual RBE2 elements at

the head of the connection, one to connect to the inner row of nodes, the other to

connect to the washer layer nodes. The connector location can either be on the edge of

the hole, center of the hole, midpoint in between the two holes or on the second row

of nodes which form the washer layer.

Figure 9.CFG optistruct 55 bolt (washer 2) *filter bolt *style bolt 0 *head rigidlink 1 1 rigidlink 1 2 *body 0 rigid 1 1 cfg_optistruct_55_bolt - OptiStruct bolt (washer 2 alt)

- Creates RBE2 elements for the head and the body. There are two individual RBE2 elements at

the head of the connection, one to connect to the inner row of nodes, the other to

connect to the washer layer nodes. The RBE2 head element that connects to the washer

layer nodes only connects to every other node on the washer layer. The connector

location can either be on the edge of the hole, center of the hole, midpoint in

between the two holes or on the second row of nodes which form the washer layer.

Figure 10.CFG optistruct 56 bolt (washer 2 alt) *filter bolt *style bolt 0 *head rigidlink 1 1 rigidlink 1 3 *body 0 rigid 1 1 - OptiStruct bolt (washer 1)

- Creates RBE2 elements for the head and body. The head elements project and connect

to the nodes of the adjoining shell elements which form the hole and also the second

row of nodes which form the washer layer. The connector location can either be on the

edge of the hole, center of the hole, midpoint in between the two holes or on the

second row of nodes which form the washer layer.

Figure 11.CFG optistruct 57 bolt (washer 1) *filter bolt *style bolt 0 *head rigidlink 1 12 *body 0 rigid 1 1 cfg_optistruct_57_bolt - OptiStruct bolt (washer 1 alt)

- Creates RBE2 elements for the head and body. The head elements project and connect

to the nodes of the adjoining shell elements which form the hole and also the second

row of nodes which form the washer layer. The head only connects to every other node

on the washer layer. The connector location can either be on the edge of the hole,

center of the hole, midpoint in between the two holes or on the second row of nodes

which form the washer layer.

Figure 12.CFG optistruct 58 bolt (washer 1 alt) *filter bolt *style bolt 0 *head rigidlink 1 13 *body 0 rigid 1 1 cfg_optistruct_58_bolt_washer1_alt - OptiStruct hinge

- Creates RBE2 elements for the head and the body. The head elements project and connect to the nodes of the adjoining shell elements which form the hole. The connector location can either be on the edge of the hole, center of the hole, midpoint in between the two holes or on the second row of nodes which form the washer layer. The degrees of freedom are constrained in the x, y, z, rot x, rot z for the dependant nodes.

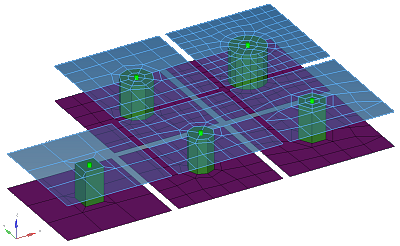

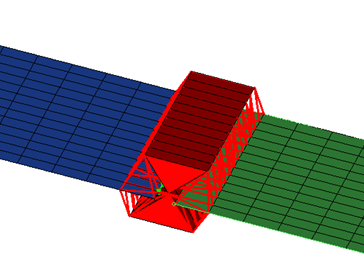

- OptiStruct bolt (cylinder rigid)

- Creates an RBE2 element for the body as well as for the head elements.

- OptiStruct (cylinder bar)

- Creates a CBEAM element for the body and RBE2 elements for the head elements.

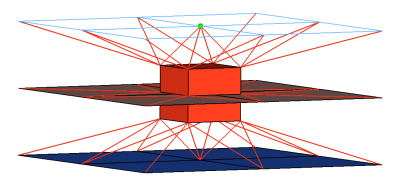

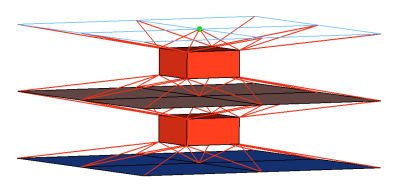

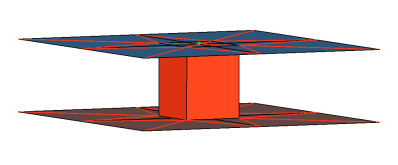

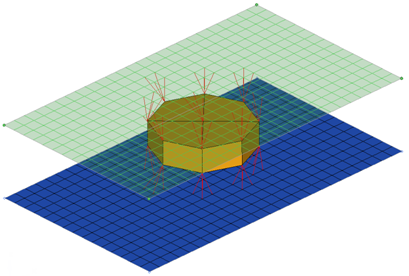

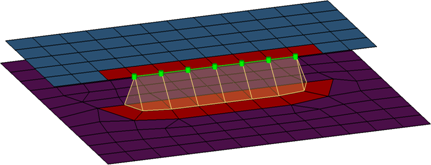

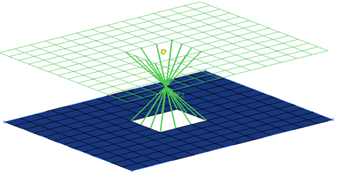

- OptiStruct acm (equivalenced-(T1+T2)/2)

- Creates hexa element with RBE3 elements projecting and connecting to the surrounding shell elements. This realization uses the shell thickness to calculate the hexa offset from the shell elements. In the case where the model is a 3T connection, the acm (equivalenced-(T1+T2)/2) realization will join the hexa elements.

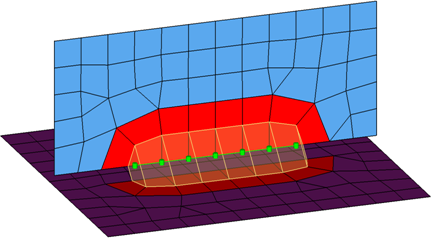

- OptiStruct acm (detached-(T1+T2)/2)

- Creates hexa element with RBE3 elements projecting and connecting to the surrounding shell elements. This realization uses the shell thickness to calculate the hexa offset from the shell elements. In the case where the model is a 3T connection, the acm (detached-(T1+T2)/2) realization will not join the hexa elements.

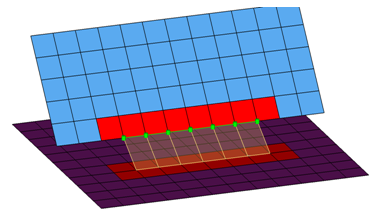

- OptiStruct acm (shell gap)

- Creates hexa element with RBE3 elements projecting and connecting to the surrounding shell elements. This realization does not use the shell thickness to calculate the hexa offset, therefore the hexa will project and be touching the shell elements.

- OptiStruct acm (shell gap + coating)

- This realization creates one hexa cluster per connector and realizes a node to node

connection to the linked shell meshes by adjusting it (shell coating). Different

patterns are available. This is driven by the number of hexas. The appearance can be

influenced via the diameter and the washer layer activation.

Figure 19.CFG optistruct 72 acm (shell gap + coating) *filter spot *style acm 4 *body 0 hex8 1 1 - OptiStruct pie (rigid spider)

- This realization prepares a circled shell mesh from a certain number of segments for each link, so the mesh is adjusted to a rigid element created with the independent node centered in the circular arranged dependent nodes. The independent nodes themselves are connected by an additional rigid element.

- OptiStruct acm (general)

- This realization type consolidates several ACM definitions into one general, flexible ACM definition. Besides mid thickness, constant thickness and maintain gaps, the definition of several coats with different hexa pattern is available.

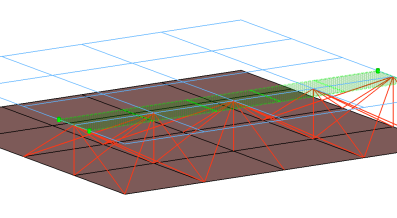

- OptiStruct penta (mig+L)

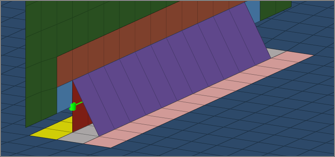

- This realization supports Lap-joints and creates PENTA element for the body. Surrounding

shell/solid elements are projected and connected with RBE3 elements. This realization

supports the creation of PENTA elements on one side or on both sides of the joint, and

provides a fitted/equilateral option for the PENTA creation.

Figure 22.CFG optistruct 76 penta (mig + L) *filter spot *style mig 1 *head rbe3 1 0 *body 0 penta6 1 1 - OptiStruct penta (mig+T)

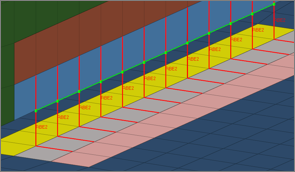

- This realization supports T-joints and creates PENTA element for the body. Surrounding

shell/solid elements are projected and connected with RBE3 elements. This realization

supports the creation of PENTA elements on one side or on both sides of the joint, and

provides a right-angled option.

Figure 23.CFG optistruct 77 penta (mig + T) *filter spot *style mig 2 *head rbe3 1 0 *body 0 penta6 1 1 - OptiStruct penta (mig+B)

- This realization supports Butt-joints and creates PENTA element for the body. Surrounding

shell/solid elements are projected and connected with RBE3 elements. This realization

supports the creation of PENTA elements on one side or on both sides of the joint. The

non-normal option needs to be ON/Active for this realization.

Figure 24.CFG optistruct 78 penta (mig + B) *filter spot *style mig 3 *head rbe3 1 0 *body 0 penta6 1 1 - OptiStruct cweld (GA-GB PARTPAT)

- Creates 1d CWELD element via GA-GB PARTPAT.

- OptiStruct cweld (GS PARTPAT)

- Creates 0D CWELD element via GS PARTPAT.

- OptiStruct cweld (GA-GB ELPAT)

- Creates 1D CWELD element via GA-GB ELPAT.

- OptiStruct cweld (GS ELPAT)

- Creates 0D CWELD element via GS ELPAT.

- OptiStruct cweld (GA-GB ELEMID)

- Creates 1D CWELD element via GA-GB ELEMID.

- OptiStruct cweld (GS ELEMID)

- Creates 0D CWELD element via GS ELEMID.

- OptiStruct cweld (GA-GB GRIDID)

- Creates 1D CWELD element via GA-GB GRIDID.

- OptiStruct cweld (GS GRIDID)

- Creates 0D CWELD element via GS GRIDID.

- OptiStruct cweld (GA-GB ALIGN)

- Creates 1D CWELD element via GA-GB ALIGN.

- OptiStruct rbe3-celas1-rbe3

- Creates RBE3 element for the head and zero length CELAS1 element for the body. The head

elements project and connect to the nodes of the adjoining shell elements. The degrees

of freedom are constrained in the x, y, z, rot x, rot y, rot z for the dependant

nodes.

Figure 34.CFG optistruct 89 rbe3-celas1-rbe3 *filter spot *head rbe3 1 0 dofs=123456 *body 0 spring 1 0 - OptiStruct seam-quad (angled+capped+L)

- Creates a quad row with tria caps at the seam ends. In addition, a certain pure quad element pattern is created around the seam elements (shown here in red). These elements normally get imprinted into the shell links. The exact geometry of the seam can be influenced by certain attributes in the Seam panel.

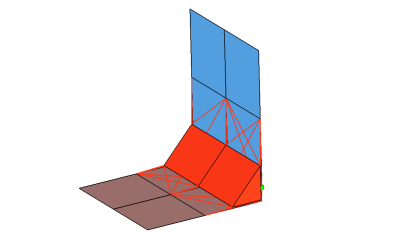

- OptiStruct seam-quad (angled+capped+T)

- Creates a quad row with tria caps at the seam ends. In addition, a certain pure quad element pattern is created around the seam elements, shown here in red. These elements normally get imprinted into the shell links. The exact geometry of the seam can be influenced by certain attributes in the Seam panel.

- OptiStruct seam-quad (vertical+angled)

- Creates two quad rows-the first one perpendicular to the opposite shell link, and the second one with a certain angle to the first one. In addition, a certain pure quad element pattern is created around the seam elements, shown here in red. These elements normally get imprinted into the shell links. The exact geometry of the seam can be influenced by the angle value.

- OptiStruct seam-quad (angled)

- Creates one quad row under a certain angle. The angle is measured between the quad row and the perpendicular projection from the free edge to the opposite shell link. In addition, a certain pure quad element pattern is created around the seam elements, shown here in red. These elements normally get imprinted into the shell links. The exact geometry of the seam can be influenced by the angle value.

- OptiStruct penta (mig)

- Creates penta elements with RBE3 elements projecting and connecting to the surrounding

shell elements. This realization supports many different use cases, including T-joint,

angled T-joint, lap joint and butt joint.

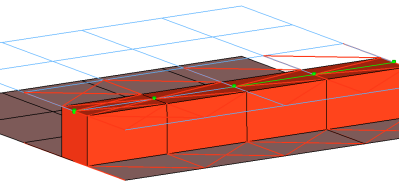

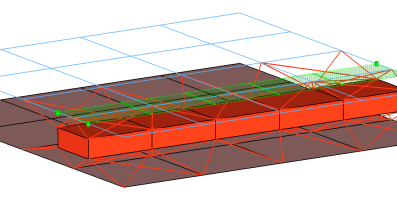

Figure 39.CFG OptiStruct 105 penta (mig) *filter seam *style continuous 3 *head rbe3 1 0 *body 0 penta6 1 1 cfg_optistruct_105_penta - OptiStruct hexa (adhesive)

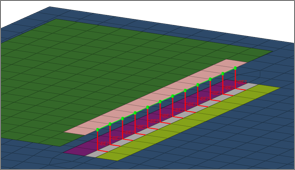

- Creates a row of hexa elements for the body and numerous RBE2/RBE3 elements for the head. The head elements project and connect to the nodes of the adjoining shell elements. If there is a direct normal project then an RBE2 elements will be used, if there are only non-normal projections then RBE3 elements will be created. The hexa elements are projected so that they touch the shell elements of the connecting components.

- OptiStruct cfast_elem (GA-GB)

- Creates 1D CFAST element of type ELEM.

- OptiStruct cfast_elem (GS)

- Creates 0D CFAST element of type ELEM.

- OptiStruct cfast_prop (GA-GB)

- Creates 1D CFAST element of type PROP.

- OptiStruct cfast_prop (GS)

- Creates 0D CFAST element of type PROP.

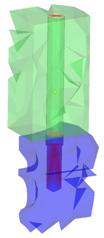

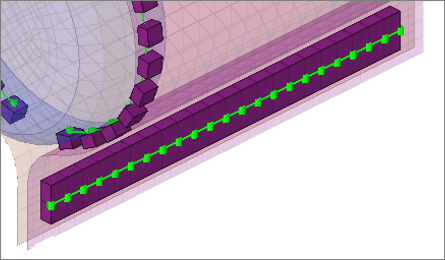

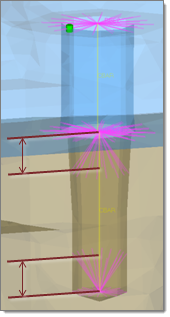

- OptiStruct HILOCK

- Creates 1D elements that are constructed out of existing RBAR, CBAR, and CBUSH elements. The outer extensions represent the thicknesses of the outer shell elements. The inner nodes of the RBAR element are connected to the shell elements, whereas the inner nodes of the CBAR elements are coincident to the shell nodes only. CBUSHes are created between the appropriate connected and coincident nodes. Each outer node connects one CBAR and one RBAR. Each HLOCK connection gets its own coordinate system which has a z-axis that is collinear to the HILOCK direction. All affected nodes are assigned to the coordinate system. The coordinate system is taken into account for the DOF definition of the CBAR elements, for the stiffness calculation of the CBUSH elements, and for the DOF of the node constraint.

- OptiStruct clip (washer nodes)

- Creates a single RBE2 element for the body. The element projects and connects to the nodes

which form the washer layer. The connector location can either be on the edge of the

hole, center of the hole, midpoint in between the two holes or on the second row of

nodes which form the washer layer.

Figure 46.CFG optistruct 112 clip (washer nodes) *filter bolt *style bolt 12 *head *body 0 rigidlink 1 1 - OptiStruct bolt (step hole)

- This realization creates a CBAR element for the bolt shaft, and connects to the solids' nodes with numerous RBE2 based on the given bolt/hole parameters. It also, connects two solids through holes, or it connects one solid through a hole with a solid blind hole.

- OptiStruct bolt (threaded step hole)

- Connects two solids through holes or connects one solid through a hole with a solid blind

hole. A thread length can be defined to define the dimensions of the rigid elements

connecting the bolt shaft models as a bar.

Figure 48.CFG optistruct 115 bolt (threaded step hole) *filter bolt *style bolt 7 *head rigidlink 1 1 *body 0 bar2 1 1 *post prop_stepboltholes.tcl - OptiStruct adhesive-hemmings

- This realization type is used for modeling roll hemmings, where the outer shell is bent

around the inner shell. The inner shell is connected to the outer shell on one side

with simple hexa adhesive, and the other side is connected with RBE2 elements. A

definable orientation node decides which side the hexa adhesive should be used. This

seam realization type is capable of connecting three layers that contains two

components.

Figure 49.CFG optistruct 116 adhesive-hemmings *filter area *style adhesive 3 *head rbe3 1 0 *body 1 hex8 1 1 rigid 1 0 *post prop_nastran_acm.tcl - OptiStruct penta continuous (mig+L)

- This realization supports Lap-joints and creates PENTA element for the body. Surrounding

shell/solid elements are projected and connected with RBE3 elements. This realization

supports the creation of PENTA elements on one side or on both sides of the joint, and

provides a fitted/equilateral option for the PENTA creation.

Figure 50.CFG optistruct 117 penta (mig + L) *filter seam *style continuous_mig 1 *head rbe3 1 0 *body 0 penta6 1 1 - OptiStruct penta continuous (mig+T)

- This realization supports T-joints and creates PENTA element for the body. Surrounding

shell/solid elements are projected and connected with RBE3 elements. This realization

supports the creation of PENTA elements on one side or on both sides of the joint, and

provides a right-angled option.

Figure 51.CFG optistruct 118 penta (mig + T) *filter seam *style continuous_mig 2 *head rbe3 1 0 *body 0 penta6 1 1 - OptiStruct penta continuous (mig+B)

- This realization supports Butt-joints and creates PENTA element for the body. Surrounding

shell/solid elements are projected and connected with RBE3 elements. This realization

supports the creation of PENTA elements on one side or on both sides of the joint.

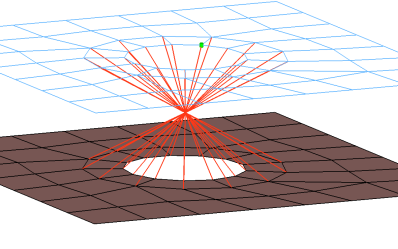

Figure 52.CFG optistruct 119 penta (mig + B) *filter seam *style continuous_mig 3 *head rbe3 1 0 *body 0 penta6 1 1 - OptiStruct wagonwheel

- This realization creates RBE2 elements for the body, and projects and connects to the hole

edge nodes with RBE3 elements.

Figure 53.CFG optistruct 120 wagonwheel *filter bolt *style bolt 0 *head rbe3 1 0 *body 0 rigid 1 1 cfg_nastran_120_wagonwheel - OptiStruct adhesives

- Creates a row of hexa/penta elements for the body and numerous RBE2/RBE3 elements for the head. The head elements project and connect to the nodes of the adjoining shell elements. If there is significant curvature in the area connector then penta elements will be created, otherwise hexa elements will normally be created. If there is a direct normal project then an RBE2 elements will be used, if there are only non-normal projections then RBE3 elements will be created.

- OptiStruct hemming

- Creates RBE3 elements for the body, the head elements project and connect to the nodes of

the adjoining shell elements.

Figure 55.CFG OptiStruct 122 hemming *filter area *style adhesive 1 *head *body 0 rbe3 1 1 cfg_optistruct_122_hemming - OptiStruct CGAP(G)

- This realizations creates a CGAP element for the body, which projects and connects to the

adjoining shell/solid nodes.

Figure 56.CFG optistruct 123 CGAP(G) *filter spot *head *body 0 gap 1 1 *post prop_opti_gap.tcl - OptiStruct bolt (collapse rigid)

- This realization creates a single RBE2 element for the body. The element projects and

connects to the nodes of the adjoining shell/solid elements which form the hole.

Figure 57.CFG optistruct 124 bolt (collapse Rigid) *filter bolt *style bolt 14 *head *body 0 rigidlink 1 12 - OptiStruct seam-quad LTB

- Serves and realizes t-welds, lap-welds and butt-welds simultaneously. The weld type is identified automatically based on the orientation of the links to each other.

- OptiStruct seam-rigid LTB

- Serves and realizes t-welds, lap-welds and butt-welds at the same time. The weld type is identified automatically based on the orientation of the links to each other.

- OptiStruct hexa (adhesive - shell gap)

- This realization creates rows of HEXA elements for the body. The HEXA elements project and connect to the adjoining shell/solid elements by touching them.

- OptiStruct hexa (spot tie)

- Creates hexa elements between shell and/or solid elements in order to connect them using a tie contact definition. The hexa element nodes will project and touch the shell and/or solid element faces. During the realization, a default tie contact and referencing main and secondary sets are created; unless defined differently, the hexas are assigned a default property and material, and are organized into a component with the same name base as the property.

- OptiStruct cbush (spot tie)

- Creates bush (CBUSH) elements between shell and/or solid elements in order to connect them using a tie contact definition. The bush element nodes will project and touch the shell and/or solid element faces. During the realization, a default tie contact and referencing main and secondary sets are created; unless defined differently, the bushs are assigned a default property, and are organized into a component with the same name base as the property. If no specific bush coordinate system is defined, the bush elements are defined with a vector x1, x2, and x3 normal to it.

- OptiStruct hexa (seam tie)

- Creates hexa elements between shell and/or solid elements in order to connect them using a tie contact definition. The hexa element nodes will project and touch the shell and/or solid element faces. During the realization, a default tie contact and referencing main and secondary sets are created; unless defined differently, the hexas are assigned a default property and material, and are organized into a component with the same name base as the property.

- OptiStruct hexa (area tie)

- Creates hexa elements between shell and/or solid elements in order to connect them using a tie contact definition. The hexa element nodes will project and touch the shell and/or solid element faces. During the realization, a default tie contact and referencing main and secondary sets are created; unless defined differently, the hexas are assigned a default property and material, and are organized into a component with the same name base as the property.

- OptiStruct cbush (rigid)

- Creates bush (CBUSH) elements between shell and/or solid elements in order to connect them using rigid (RBE3) elements. The bush element nodes will project and touch the shell and/or solid element faces. Unless defined differently, the bushs are assigned a default property, and are organized into a component with the same name base as the property. If no specific bush coordinate system is defined, the bush elements are defined with a vector x1, x2, and x3 normal to it.

Automatic Exclusion of Special Nodes During Rigid Bolt Realization

HyperMesh automatically excludes special nodes as potential secondary nodes for any rigid bodies created during bolt realization, even though they fall with the virtual Bolt Cylinder diameter. Nodes that are referred in the constraints are considered special nodes.

Property Scripts

- prop_hinge.tcl

This script is called while creation of HINGE– custom config welds in the connector bolts panel. This script performs the tasks when the Systems option is active in the connector Bolt panel (such as “Single System”,”1- System per layer” or 2- Systems per layer).

This Script Assigns both reference and analysis systems ID to weld element nodes of each Bolt (Hinge) created during realization process.

- prop_cylinder.tclUsed while creating bolt (cylinder rigid) and bolt (cylinder bar) in the Bolt panel (Abaqus, Nastran, OptiStruct). It organizes the realized bolt elements into the respective components based upon the*HEAD and the *BODYinformation of the bolt:

- A collector with the name Rigid_M<diameter> is created. This component contains all of the rigid head elements and the rigid body elements, if available.

- A collector with the name Beam_M<diameter> is created. This component contains all of the bar2 head elements, if available. This component then gets a property Beam_M assigned (*BEAMSECTION or PBEAM).

- prop_nastran_acm.tclThis script is used in the Nastran and OptiStruct user profiles during the creation of the following configurations:

- acm – equivalence/detached –(T1+T2)/2, and shell gap custom config welds in the Spot panel,

- seam hexa adhesive and seam hexa (RBE2-RBE3) in the Seam panel, and

- Area adhesives in the Area panel.

The script performs the following tasks:- Organizes the realized Solid Hexa weld elements created during realization process into components with names based on the realization, such as solid_spot_acm_detached, solid_seam_hexa_adhesive_shell_gap, or solid_area_hexa_adhesive_shell_gap. Components and the connected RBE’s created as the *HEAD type are organized into components using similar naming, such as rbe3_spot_acm_detached, rbe3_seam_hexa_adhesive, or rbe3_area_hexa_adhesive.

- This script creates property collectors, again using names based on the

realization such as solid_spot_acm_detached, solid_seam_hexa_adhesive_shell_gap,

or solid_area_hexa_adhesive_shell_gap.

- These property collectors are created with the PSOLID card associated with them, and are referenced in the above created components containing the Solid Hexa weld elements.

- In addition, this script also updates the weights of any RBE3 that is almost zero, because weight factors close to 0.0 cause Nastran and OptiStruct solvers to generate incorrect results.

Note: New components and properties will only be created if they do not already exist; otherwise the existing components and properties are used. For this reason, comps/props will not always follow the naming conventions given here, because preexisting ones might already have different names.Also, when creating realizations with a mid-thickness option, the naming conventions include the presence of the mid-thickness. For example, when creating a hexa (RBE2-RBE3) configuration using a mid-thickness option:- Solid elements will be organized into a Component named solid_seam_ hexa_RBE2_RBE3_mid_thick

- RBE3 elements will be organized into a Component named rbe3_seam_ hexa_RBE2_RBE3_mid_thick

- RBE2 elements will be organized into a Component named rbe2_seam_ hexa_RBE2_RBE3_mid_thick

- Properties will be created with the name solid_seam_ hexa_RBE2_RBE3_mid_thick

- Materials will be created with the name solid_seam_ hexa_RBE2_RBE3_mid_thick

- prop_cweld.tclThis script is called while creation of all the CWELD GA-GB and GS– custom config welds in the Spot panel. Theses include PARTPAT, ELPAT, ELEMID, GRIDID, ALIGN. It performs the following tasks:

- Assigns the attributes to the CWELD weld element created during the realization process, which is either a rod element [GA-GB] or mass Element [GS] of the types PARTPAT, ELPAT, ELEMID, GRIDID or ALIGN.

- Creates the property collector with the name prop_<id> with the PWELD card associated with it. This property is referenced to the CWELD element created during realization.

- This script also updates the weld radius value in the CWELD card. The diameter value is either defined by you on the Spot panel, or is taken from the dvst (diameter versus thickness) file.

Note: This script is called if the CWELD GA-GB and GS– custom config welds and shell gap custom config welds across Nastran and OptiStruct user profiles. - prop_opt_nas_cfast.tclThis script is called while creation of all the CFAST GA-GB and GS– custom config welds in the Spot panel. Theses include ELEM, and PROP. It performs the following tasks:

- Assigns the attributes to the CFAST weld element created during the realization process, which is either a rod element [GA-GB] or mass Element [GS] of the types ELEM or PROP.

- Creates the property collector with the name PFAST_<diameter> with the PFAST card associated with it. This property is referenced to the CFAST element created during realization.

- This script also updates the weld diameter value in the CFAST card. The diameter value is either defined by you on the Spot panel, or is taken from the dvst (diameter versus thickness) file.

Note: This script is called for the CFAST GA-GB and GS– custom config welds across Nastran and OptiStruct user profiles. - prop_opt_nas_hilock.tcl

This script is used while creation of HILOCK custom config welds in the Spot panel from the Nastran and OptiStruct user profile.

This script does the following tasks:- Organizes the realized 1D weld elements (RBAR, CBAR, CBUSH) created during realization process into a component named HiLock components.

- This script will create the following property collectors:

- HiLock_PBAR_<diameter>: This property collector is created with the PBAR card associated with it. The RBAR elements reference to this property. The attributes are calculated depending on the used diameter in the Spot panel during realization.

- HiLock_PBUSH_<translational stiffness>_<rotational stiffness>: These property collectors are created with the PBUSH card associated with them. The CBUSH elements reference to this property. The attributes are calculated depending on the HILOCK material you select and the properties and materials of the connected shells (PSHELL and/or PCOMP).

- This script will create the following load collector:

- HiLock_SPC6

- This load collector is created and the SPCs, which are created for each HiLock will be moved into this collector.

- This script will create the following system collector:

- HiLock

- This system collector is created and the systems created during the realizations will be moved into this collector. If the system collector exists already the new created systems will be moved into the same collector.

- If a HiLock material is not chosen, a default material is created:

- HiLock_MAT1

- This material will be assigned to PBAR cards, and can be found in the following folder of the installation directory: [hm_scripts_dir]/connectors/HiLock_Mats.

Note: This script is called if the realization CFG Nastran 111 HILOCK or CFG OptiStruct 111 HILOCK is used. - prop_stepboltholes.tclThe script performs the following tasks:

- Organizes the CBAR elements into a component with the name HM_Bolt_CBAR.

- Organizes the RBE2 elements into a component with the name HM_Bolt_RBE2.

- Creates a property with the name HM_PBAR and assigns it the PBAR card image.

Note: New components and properties will only be created if their are not any components and properties with the same names that already exist; otherwise the existing components and properties are used. - 2022.1The script performs the following tasks:

- Organizes the CGAP elements into a component with the name Realize2001.

- Creates a property with the name PGapProp, and assigns the card image PGAP.

Note: New components and properties will only be created if their are not any components and properties with the same names that already exist; otherwise the existing components and properties are used. - prop_opt_tie_contacts.tclThe script performs the following tasks:

- Creates TIE interfaces (groups) with the name ADHESIVE_HEXA_TIE_CONTACT_PID _# and the card image TIE. The groups reference the independent/dependent links' main sets and the nodes' secondary sets (# is the ID of the link components).

- Organizes the links' component elements into sets with the name ADHESIVE_HEXA_MAIN_PART_SET_PID_# and the card image SET_ELEM. The sets are referenced by the above interface groups (# is the ID of the link component).

- Organizes the solids‘ nodes on the links into sets with the name ADHESIVE_HEXA_SECONDARY_NODE_SET_PID _# and the card image SET_GRID. The sets are referenced by the above interface groups (# is the ID of the link component).

- Creates components with the name ADHESIVE_HEXA_COMP_PID _#_# for the connector SOLID elements (# is the ID of the link component).

- Creates properties with the name ADHESIVE_HEXA_PROP_PID_ #_# and the PSOLID cardimage, and assigns them to respective SOLID components (# is the ID of the link component).

- Creates a material with the name ADHESIVE_HEXA_MAT_PID _#_# and the card image MAT1, and assigns it to respective SOLID properties (# is the ID of the link component).