OS-E: 3025 Optimization of the Modal Frequencies of a Disc using Constrained Beading Patterns

Finding a good reinforcement pattern for a single modal frequency is difficult when dealing with beaded plates since adding stiffness in one direction often reduces stiffness in another direction.

The problem posed by finding a good reinforcement pattern for four modal frequencies simultaneously is more than four times more difficult. Add to that the difficulty constraints on the variety of reinforcement patterns, and the problem becomes a formidable task.

Model Files

Refer to Access the Model Files to download the required model file(s).

- disc_radial.fem

- disc_cyclic.fem

Model Description

By implementing topography optimization and pattern grouping, the task is greatly simplified and good quality results are quickly generated. All optimization set up is done using the Optimization panel and its subpanels in HyperMesh.

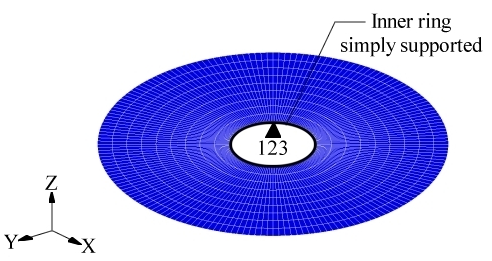

Figure 1. Constraints on the Disc Model

The objective for the model is to increase the sum of the frequencies of the first four normal modes of the disc. This is achieved by using the WFREQ response type. The WFREQ response is the sum of the inverse eigenvalues of the chosen frequencies. This is done in order to assign higher weight to the earlier modes than the latter ones.

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| DTPG | 1 | PSHELL | 1 | ||||||

| + | 5.0 | 60.0 | YES | 2.5 | NORM | SPC | |||

| + | PATRN | 2 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 1.0 |

The anchor node is set at the center of the disc and the first vector points in the z direction. The nodes in the center ring are removed from the design region by choosing Spc in the Boundary skip option in the topography subpanel. No other additions to the finite element model were required.

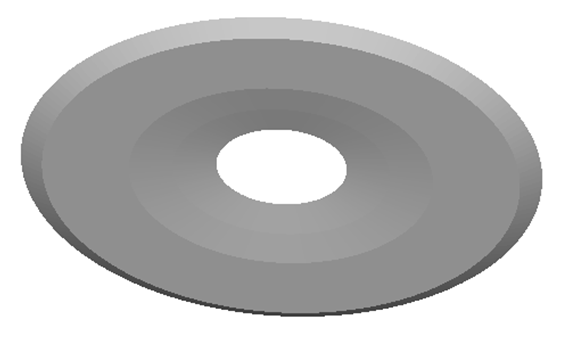

Figure 2. Solution for the Circular Bead Pattern Method

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| DTPG | 1 | PSHELL | 1 | ||||||

| + | 5.0 | 60.0 | YES | 2.5 | NORM | SPC | |||

| + | PATRN | 4 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 1.0 |

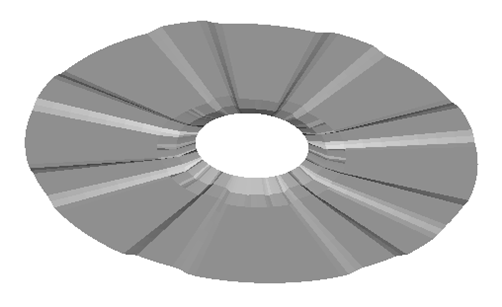

Figure 3. Solution for the Radial Bead Pattern Method

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| DTPG | 1 | PSHELL | 1 | ||||||

| + | 5.0 | 60.0 | YES | 2.5 | NORM | SPC |

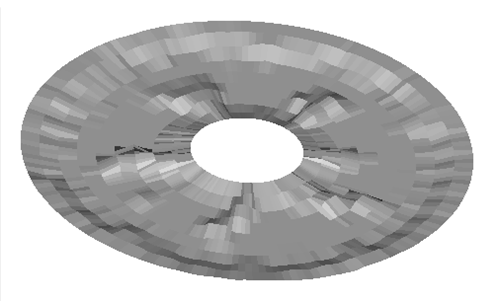

Figure 4. Solution for the Default Pattern Method

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| DTPG | 1 | PSHELL | 1 | ||||||

| + | 5.0 | 60.0 | YES | 2.5 | NORM | SPC | |||

| + | PATRN | 41 | 0.0 | 0.0 | 0.0 | 0.0 | 1.0 | 0.0 | |

| + | PATRN2 | 4 | 1.0 | 0.0 | 0.0 |

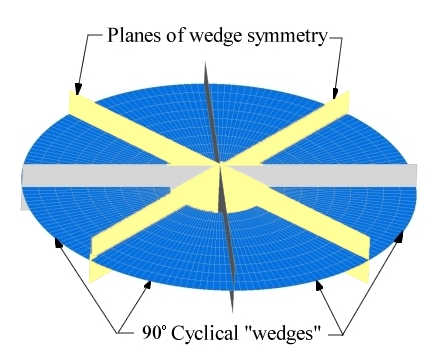

Figure 5. Cyclical Symmetry Pattern for 4 Symmetric Wedges

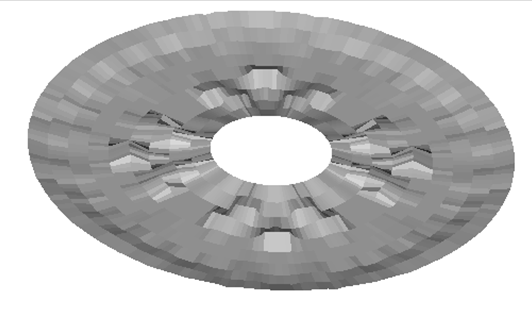

Figure 6. Solution for the Cyclical Pattern Method with 4 Symmetric Wedges

Results

| Mode # | Baseline | Circular | Radial | Default | Cyclical |

|---|---|---|---|---|---|

| 1 | 18.7 | 47.3 | 45.3 | 51.1 | 50.4 |

| 2 | 18.7 | 47.3 | 45.4 | 52.7 | 50.4 |

| 3 | 20.1 | 73.0 | 43.8 | 69.1 | 68.5 |

| 4 | 34.8 | 61.5 | 60.2 | 66.3 | 66.7 |

| 5 | 34.8 | 61.5 | 60.6 | 68.4 | 67.5 |

| 6 | 74.4 | 113.0 | 93.0 | 115.0 | 117.0 |