RD-E: 5502 Rotating Fan Blade Ice Impact and Failure

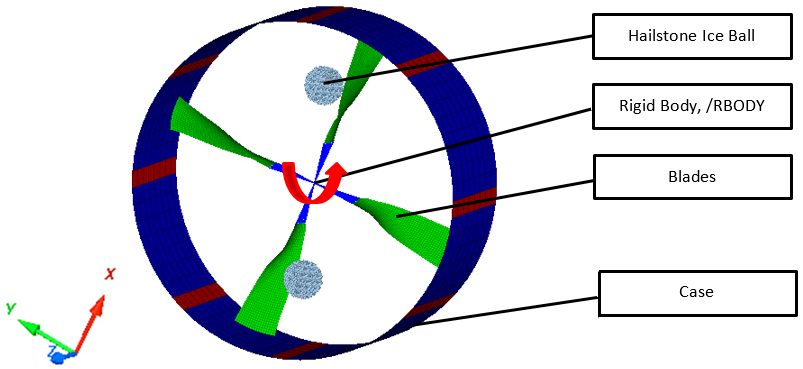

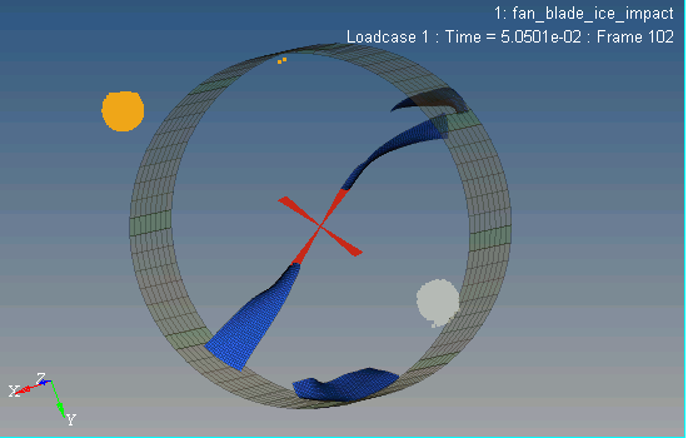

Two hailstone ice balls are added to the model from RD-E: 5501 Fan Blade Rotation Initialization to study the deformation and failure of the blades when impacted.

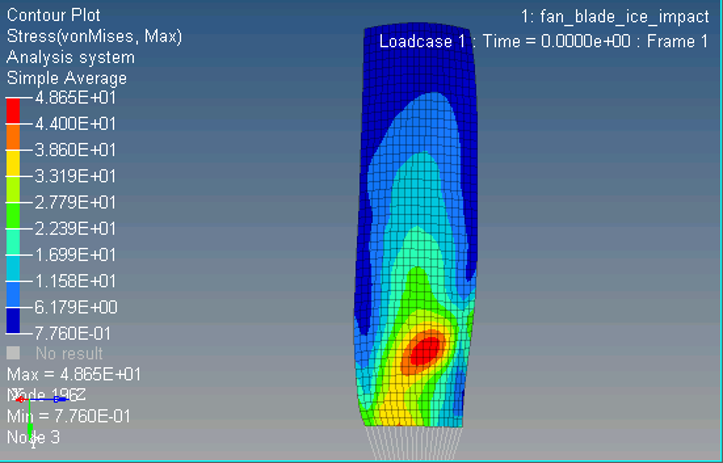

The stress in the blades, due to rotation is accounted for by using Radioss state files, /STATE. A Johnson-Cook Failure model, /FAIL/JOHNSON, is applied to the blade elements to take into account material failure.

Options and Keywords Used

- Centrifugal force pre-load in rotating structures

- State files used to apply pre-load stress in a new simulation (/STATE)

- Implicit simulation options (Implicit Solution)

- Centrifugal force field (/LOAD/CENTRI)

- Rotational velocity about an axis (/INIV/AXIS/Z/1)

- Boundary Condition remove in Engine file (/BCSR)

- Johnson-Cook failure model (/FAIL/JOHNSON)

# To save the full stress use these 3 STATE SHELL options

/STATE/SHELL/STRESS/FULL

/STATE/SHELL/AUX/FULL

/STATE/SHELL/STRAIN/FULL

# time to write state file and which part

/STATE/DT

0.1 0.1

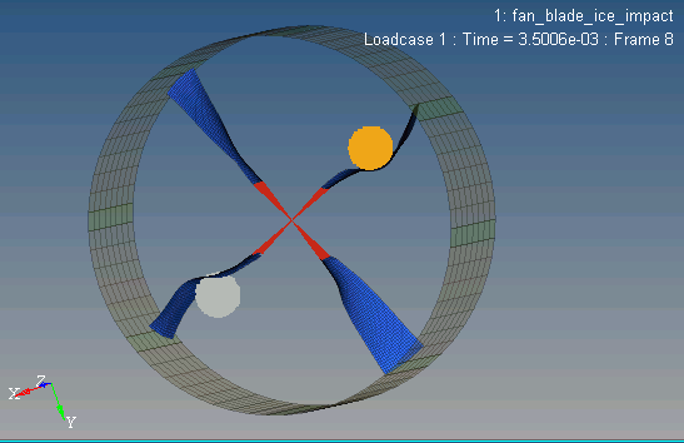

1Now the hailstone ice ball model and the stress State file from the implicit simulation are included in the full simulation. The initial rotational velocity on the blades is included in the Engine file (/INIV/AXIS/Z/1) but could have also been be added Starter file using /INIVEL/AXIS. The ice impact simulation is ran for 0.08 seconds.

Input Files

Refer to Access the Model Files to download the required model file(s).

The model files used in this example are available in:

/radioss/example/55_Fan_Blade_Out_FBO

Model Description

Figure 1. Blades with Case and Hail Ice Balls

Units: mm, s, Mg, N, and MPa

- Blade Titanium Material Properties

- Density

- Young's modulus

- 113400

- Poisson's ratio

- 0.342

- Yield stress

- 1098

- Plastic hardening parameter

- 1092

- Plastic hardening exponent

- 0.93

- Failure Material Properties

- D1

- -0.09

- D2

- 0.25

- D3

- -0.05

- D4

- 0.014

- Ifail_sh

- 1

- Case Steel Material Properties

- Density

- Young's modulus

- 210000

- Poisson's ratio

- 0.3

- Yield stress

- 200

- Plastic hardening parameter

- 450

- Plastic hardening exponent

- 0.5

- Maximum stress

- 425

- Ice Ball Material Properties

- Density

- Young's modulus

- 8304

- Poisson's ratio

- 0.2

- Yield stress

- 10.3

- Ice Ball Material Properties

- Plastic hardening parameter

- 2500

- Plastic hardening exponent

- Blade Center constrained all directions, except Rz

- Imposed Rotational Speed = 1000 = 104.72

- Edges of case are fully constrained in X, Y, Z directions

Model Method

This simulation builds on the results in RD-E: 5501 Fan Blade Rotation Initialization. The blades are impacted by two 3.07 kg hailstone ice balls with a radius of ~ 85 mm. A Johnson-Cook Failure model is added to the blade material to demonstrate how material failure can be modeled. The Johnson-Cook failure model relates plastic failure strain as a function of stress triaxiality (normalized mean stress). Additional details can be found in Materials of the Radioss User Guide, /FAIL/JOHNSON and /FAIL/TAB1.

Results

Figure 2. Initial Stress on Blade at t=0.0

Figure 3. Initial Impact, t=3.5e-3

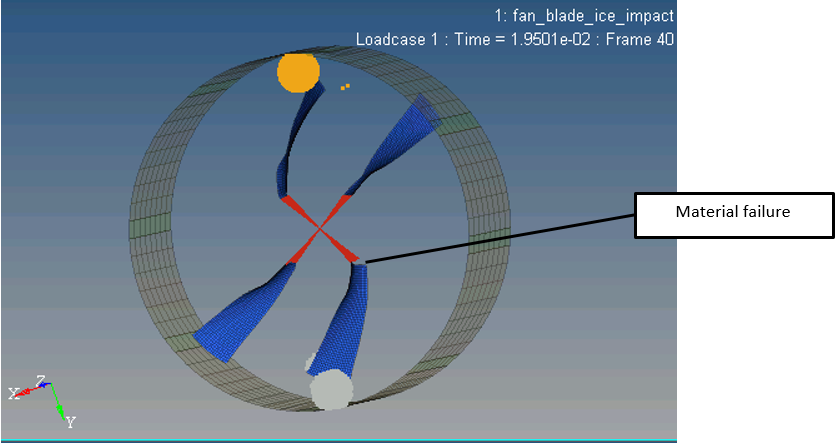

Figure 4. Blade Material Failure

Figure 5. Blade Failure and Case Impact

Conclusion

The stress in the blades from steady state rotation can be correctly accounted by including stress state files from a separate simulation. This saves time since it is not necessary to rerun the pre-load simulation for every design change of the case. The Johnson-Cook failure model accounts for the material failure of the blades due to their impact with hailstone ice balls.