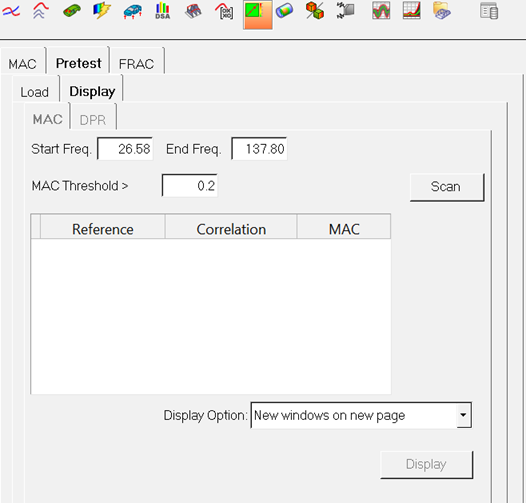

PreTest - Display Tab

The PreTest utility's Display tab allows you to filter MAC and Driving Point Residue results.

MAC

The MAC tab allows you to plot MAC for the selected nodes, frequency range, and MAC threshold.

Figure 1. PreTest - Display Tab - MAC

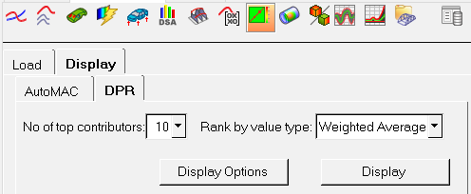

DPR

The DPR tab allows you to plot DPR for the selected nodes.

Figure 2. PreTest - Display Tab - DPR

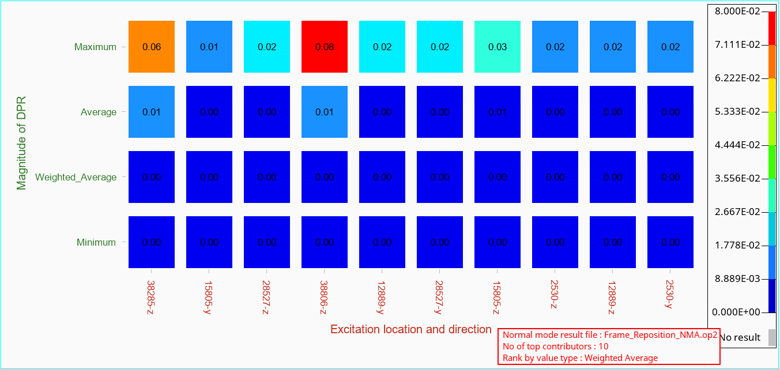

Figure 3.