/MAT/LAW69

Block Format Keyword This law is an extension of /MAT/LAW42 (OGDEN) and defines a hyperelastic and incompressible material specified using the Ogden, Mooney-Rivlin material models.

It is generally used to model incompressible rubbers, polymers, foams, and elastomers. Material parameters are computed from an engineering stress-strain curve from uniaxial tension and compression tests. It is used with shell and solid elements.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW69/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| law_ID | fct_IDblk | v | Fscaleblk | N_pair | Icheck | ||||

| fct_ID1 | |||||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material

identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material

title. (Character, maximum 100 characters) |

|

| Initial

density. (Real) |

||

| law_ID | Hyperelastic material

model type. 2 (Integer)

|

|

| fct_IDblk | Function which scales the

bulk coefficient as a function of the relative volume. 6 (Integer) |

|

| v | Poisson's ratio. Default = 0.495 (Real) |

|

| Fscaleblk | Scale factor for fct_IDblk. Default = 1.0 (Real) |

|

| N_pair | Number of material

parameter (

p and αp) pairs in the

representation of the strain energydensity function

(W). The material parameters are calculated

from the givenstress-strain curve

(fct_ID1). (N_pair ≤ 5) Default = 2 (Integer) |

|

| Icheck | Validity check of material

parameters (

p and αp).

(Integer) Parameters fitting uses the compression and

tension test data:

Parameter fitting uses only the tension test data:

|

|

| fct_ID1 | Function identifier for

the engineering stress-strain curve from uniaxial compression and

tension test. (Integer) |

Example (Mooney-Rivlin Formulation)

#RADIOSS STARTER

/UNIT/1

unit for mat

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW69/1/1

LAW69 rubber

# RHO_I

1E-9

# LAW_ID FCT_ID NU FSCALE N_PAIR ICHECK

2 0 .495 0 2 0

# FCT_ID1

2

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 3. FUNCTIONS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/2

LAW69 e.strain e.stress

# X Y

0 0

.03 .30

.06 .55

.10 .80

.20 1.4

.30 2.0

.50 2.7

.70 3.4

1.0 4.0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Example (Ogden Formulation)

#RADIOSS STARTER

/UNIT/1

unit for mat

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW69/1/1

LAW69 rubber

# RHO_I

1E-9

# LAW_ID FCT_ID NU FSCALE N_PAIR ICHECK

1 0 .495 0 2 0

# FCT_ID1

2

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 3. FUNCTIONS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/2

LAW69 e.strain e.stress

# X Y

0 0

.03 .30

.06 .55

.10 .80

.20 1.4

.30 2.0

.50 2.7

.70 3.4

1.0 4.0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

-

Radioss currently accepts test data from the

following deformation schemes:

Uniaxial tension and compression.

The input stress-strain data (fct_ID1) is engineering stress as a function of engineering strain. The engineering strain should be monotonically increasing ranging from a negative value in compression to a positive value in tension. In compression, the engineering strain should be greater than -1.0. If data in fct_ID1 is not complete (only tension data), then only tension will be considered.

- The strain energy density formulation

used depends on the law_ID.

- law_ID = 1 (Ogden

law):

(1) - law_ID = 2 (Mooney-Rivlin

law):

(2)

- law_ID = 1 (Ogden

law):

- After reading the stress-strain curve

(fct_ID1), Radioss calculates the corresponding parameter

pairs using nonlinear least-square fitting.

- For classic Ogden law, the parameter pairs are p and αp (p=1,...5, max of N_pair is 5)

- For Mooney-Rivlin law, the parameter pairs are p and αp (p=1,2, N_pair always equals 2)

- To improve the quality of the

nonlinear least square fit, it is recommended that:

- The experimental data curve represents a smooth monotonically increasing function with uniform distribution of abscissa points. The number of data points in the experimental data curve should be greater than the number of parameter pairs (N_pair).

- If N_pair ≥ 3, the test data should cover at least 100% of the tensile strain and/or 50% of the compressive strain.

- N_pair should not be set to a very large value to avoid instabilities in the fitting procedure.

- Radioss Starter outputs the "averaged error of fitting" between input (experimental) and the stress-strain curve which is calculated from the strain energy density function (W) using the corresponding material parameters determined during the fitting process. The maximum "averaged error of fitting" should not exceed 10%.

- This material law is stable when

(with p=1,...5) is satisfied for parameter pairs

for all loading conditions. By default, Radioss

tries to fit the curve by accounting for these conditions

(Icheck= 2).

If a proper fit cannot be found, then a weaker condition (Icheck= 1: ) is used. The latter is a necessary condition to enforce that the initial shear hyperelastic modulus ( ) is positive.

- Material incompressibility is

provided by using a penalty approach, which calculates the pressure proportional

to a change in density:

(3) Where, fblk is the function of fct_IDblk

The proportionality coefficient (K) is the bulk coefficient which is generally a very high value. This provides a significantly high value for the pressure-resistance when the incompressibility condition (J=1) is violated. The Jacobian (J) can be interpreted as the ratio of the current element volume with respect to the initial element volume.

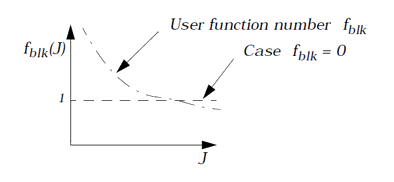

fct_IDblk provides additional control for the incompressibility (see Figure 1). It allows the scaling up of the bulk coefficient value based on the value of J. By default, the function identifier is zero and the value of the bulk scaling function is equal to 1. It is advisable to output and control the density distribution of LAW69 components to make sure that the density variation is small, that is the value of J is close to 1.

Figure 1. - Poisson's ratio v

is used only for computing the bulk modulus (K).

For pure incompressible materials, . This value of Poisson's ratio implies an infinite value for the bulk modulus (K). Therefore, the recommended Poisson's ratio for incompressible materials is (default). Higher values of the Poisson's ratio may lead to a small time step value or divergence in case of implicit and explicit simulations.

- /VISC/PRONY can be used with this material law to include viscous effects.

- Further explanation about this law can be found in "Non-Linear Elastic Deformations", by R.W Ogden, Ellis Horwood, 1984.