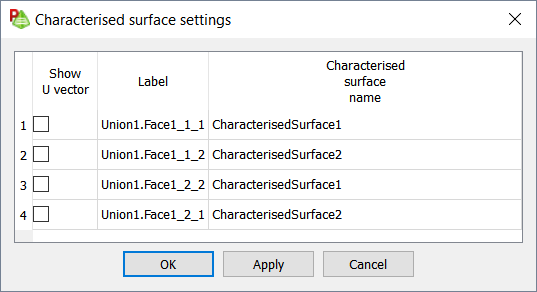

Viewing the Reference Vector Orientation for Characterised Surface Mesh Elements

Validate your model that contains characterised surface mesh elements, by viewing the reference vector orientation.

See what's new in the latest release.

The Feko Getting Started Guide contains step-by-step instructions on how to get started with Feko.

The Feko Example Guide contains a collection of examples that teaches you Feko concepts and essentials.

Feko is a comprehensive electromagnetic solver with multiple solution methods that is used for electromagnetic field analyses involving 3D objects of arbitrary shapes.

CADFEKO is used to create and mesh the geometry or model mesh, specify the solution settings and calculation requests in a graphical environment.

POSTFEKO, the Feko post processor, is used to display the model (configuration and mesh), results on graphs and 3D views.

Use POSTFEKO to validate meshed geometry and analyse and post-process results.

View the main elements and terminology in the POSTFEKO graphical user interface (GUI).

POSTFEKO has various default settings that you can configure to customise it to your preference.

A number of rendering options are available to ensure that 3D models and graphs (containing a large number of sample points) are rendered efficiently.

You can add a model, open an existing project and save the project.

Import text files, native data files and Touchstone format files.

POSTFEKO supports the export of native file formats. These files can be exported to use in other sessions or when further post-processing is required.

The terms, dataset, slice, trace and 3D result, are used extensively in the documentation. Review the definitions to get a better concept of these definitions.

Display result data on a graph to allow visual interpretation of the data in a human-readable format, as well as to communicate the results in reports and presentations.

A Cartesian surface graph is a flat colour plot with results plotted against two independent axes.

View the simulation data in a 3D view to allow visual interpretation of the data in a human-readable format, as well as to communicate the results in reports and presentations. The 3D view can also be used to verify that the CADFEKO or EDITFEKO model is correct.

Create a new 3D view to verify the model and visualise the results.

Create a sectional view of the model by using a cut plane to show internal details that would otherwise be hidden. Multiple cutplanes are supported.

Add up to four legends to a predefined location on the 3D view. Bind the legend to a specific entity (for example, far field data or mesh display), based on the results displayed in the 3D view.

Read a single point from a 3D view result by adding a quick single point annotation.

Add a single point annotation to a 3D view result. Multiple annotations can be added to a single 3D view.

Create a duplicate view of a 3D view, and copy the display settings.

Make a copy of the 3D simulation result.

Store a local copy of the underlying data that is represented by the 3D simulation result. By storing a local copy, you can modify the existing model and compare the old results to new results.

A number of display settings are available to customise the display of simulation results in the 3D view.

All 3D entities are visible by default (except for named points), provided the model contains the entity.

Show or hide the display of symmetry, the finite difference time domain (FDTD) boundary, the periodic boundary condition (PBC) boundary and the array base element for finite arrays.

Show or hide the display of the main axes, mini axes and tick marks.

A number of mesh display settings are available to give you full control of the mesh rendering in the 3D view. These settings are useful if you want to verify the model (simulation mesh).

View the display options for mesh colour, model outline, segment radius, wire coating, anisotropic media, windscreen layers and mesh normals.

Validate your model that contains multi-layered anisotropic composite media, by viewing the principal direction.

Validate your model that contains anisotropic (3D) media, by viewing the principal direction for each medium.

Validate your model that contains characterised surface mesh elements, by viewing the reference vector orientation.

Specify the mesh opacity as well as the opacity of windscreens triangles and aperture triangles.

View the visibility settings for segments, triangles, apertures, windscreens, tetrahedra, voxels, cuboids and uniform theory of diffraction (UTD) polygons and cylinders.

A number of display settings are available to customise 3D view results.

The Solver contains a number of frequency domain solution methods, as well as a time domain solution method. By default, all simulation results are obtained in the frequency domain, unless explicitly using the time analysis tool in POSTFEKO to convert the results to the time domain.

With the time analysis tool in POSTFEKO, electromagnetic scattering problems can be analysed in the time domain. The time domain results are obtained by applying an inverse fast Fourier transformation (IFFT) on the frequency domain simulation results.

Use animation to obtain a better understanding of results or export the animation to use in a presentation or report.

POSTFEKO is a useful tool to help analyse and present data in a useful format. It is often required to use the processed results in a report or presentation. To help make it easier to generate these reports, several tools are available in POSTFEKO.

Feko provides a powerful scripting language that allows you to create scripts that control CADFEKO and POSTFEKO.

POSTFEKO has a collection of tools that allow you to quickly validate the model, for example, measure distances, measure angles and finding specific mesh elements.

View the files associated and generated by POSTFEKO.

View the shortcut keys available for POSTFEKO for faster and easier operation of POSTFEKO.

EDITFEKO is used to construct advanced models (both the geometry and solution requirements) using a high-level scripting language which includes loops and conditional statements.

One of the key features in Feko is that it includes a broad set of unique and hybridised solution methods. Effective use of Feko features requires an understanding of the available methods.

Feko offers state-of-the-art optimisation engines based on generic algorithm (GA) and other methods, which can be used to automatically optimise the design and determine the optimum solution.

The Feko utilities consist of PREFEKO, OPTFEKO, ADAPTFEKO, the Launcher utility, Updater and the crash reporter.

Feko writes all the results to an ASCII output file .out as well as a binary output file .bof for usage by POSTFEKO. Use the .out file to obtain additional information about the solution.

A large collection of application macros are available for CADFEKO and POSTFEKO.

CADFEKO and POSTFEKO have a powerful, fast, lightweight scripting language integrated into the application allowing you to create models, get hold of simulation results and model configuration information as well as manipulation of data and automate repetitive tasks.

Reference information is provided in the appendix.

POSTFEKO, the Feko post processor, is used to display the model (configuration and mesh), results on graphs and 3D views.

View the simulation data in a 3D view to allow visual interpretation of the data in a human-readable format, as well as to communicate the results in reports and presentations. The 3D view can also be used to verify that the CADFEKO or EDITFEKO model is correct.

A number of display settings are available to customise the display of simulation results in the 3D view.

A number of mesh display settings are available to give you full control of the mesh rendering in the 3D view. These settings are useful if you want to verify the model (simulation mesh).

View the display options for mesh colour, model outline, segment radius, wire coating, anisotropic media, windscreen layers and mesh normals.

Validate your model that contains characterised surface mesh elements, by viewing the reference vector orientation.

Validate your model that contains characterised surface mesh elements, by viewing the reference vector orientation.

© 2022 Altair Engineering, Inc. All Rights Reserved.