3D example: Magneto thermal application (Technical paper)

Study carried out

The study proposed in the “Magneto thermal” 3D technical paper is the thermal treatment of a steel bridle.

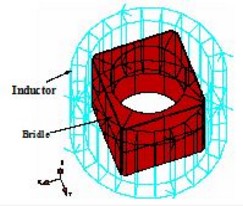

Studied device

The studied device shown in the figure below, comprises the following components:

- an inductor that generates the source field: the inductor is a cylindrical coil supplied by a sinusoidal current source

-

a charge, which corresponds to the thermal treated component:

the steel bridle

Reference to the 3D technical paper

Several computation types are possible for this device. The technical paper tacks together all these possibilities and gives the details of the characteristics in order that these cases be entered and carried out. The latter ones are briefly described below in order to exemplify different types of conceivable computations

The thermal treatment processes

The role of the surface thermal treatments of the parts made of ferrous alloys is to improve their strength to stress or (and) wear by hardening the critical surface areas.

Two thermal treatment processes of the bridle involving the induction heating are studied. These processes involve two steps presented below:

- Step 1 :Bridle heating = slow induction heating of the bridle, performed at low or high frequency, in order to obtain a minimal non-uniformity of the bridle temperature at the end of the heating;

- Step 2 :Bridle hardening = hardening of the bridle surface by quenching the part after induction heating.

The characteristics of this two-step process are depicted in the table below.

| Step | Description | Transformation | Conditions |

|---|---|---|---|

| 1 | Slow induction heating (volume or surface induction heating) | ferrite + perlite ⇒ austenite | local temperature beyond 800-850 °C |

| 2 | Natural or forced quenching | austenite ⇒ martensite | local value of cooling rate beyond a critical value, depending on the bridle material |

Treated cases

The simulations of the two-step thermal treatment of the bridle are carried out in Flux by means of the study of three cases:

- case 1: induction heating at low frequency (f = 1 kHz);

- case 2: induction heating at high frequency (f = 200 kHz);

- case 3: cooling after induction heating

Case 1

The first case represents the study of step 1 of the thermal treatment process:

It is about a slow induction heating process, performed at relatively low frequency (f = 1 kHz). The value of the penetration depth is considerable,

![]() = 2.05 mm, comparable with the thickness

of the bridle; consequently, this case corresponds to a volume

induction heating process.

= 2.05 mm, comparable with the thickness

of the bridle; consequently, this case corresponds to a volume

induction heating process.

The induced power density related to the lateral surface of the bridle is of low value. Consequently, the bridle is heated slowly, and thus a low gradient of the temperature in the entire volume of the bridle at the end of the heating is obtained.

The bridle is heated from the ambient temperature (20 °C) to approximately 1100 °C.

Case 2

The second case also concerns the study of step 1 of the thermal treatment process:

It is also about a slow induction heating process,

but performed at relatively high frequency (f = 200 kHz). The value

![]() = 0.14 mm of the penetration depth is

small in comparison with the thickness of the bridle; consequently,

this case corresponds to a surface induction heating process.

= 0.14 mm of the penetration depth is

small in comparison with the thickness of the bridle; consequently,

this case corresponds to a surface induction heating process.

Only the surface of the bridle is involved in the electromagnetic computation. The induced power density transferred at the level of the lateral surface of the bridle is also of small value. The heating of the bridle is exclusively due to the thermal conduction from the surface of the bridle, where the induced currents occur, towards the metallic volume of the bridle. The bridle is also heated slowly, and thus, a low gradient of the temperature in all the volume of the bridle at the end of the heating is obtained.

The bridle is heated from the ambient temperature (20 °C) to approximately 1100 °C.

Case 3

The third case represents the study of the second step of the thermal treatment process:

It is about the step of cooling (quenching) after induction heating. After a short period of natural cooling (in air), a rapid cooling is studied.