Extrusive mesh generator

Definition

The extrusive mesh generator permits the meshing in regular layers of the faces or of the volumes obtained by extrusion.

A base meshed line is « shifted » along a meshed path, following a simple motion of translation or rotation. Thus, a meshed face in quadrangles is generated. The same method is used for the extrusive meshing of volumes. In this case, a base meshed surface is « shifted ».

The obtained elements of the extrusive mesh are :

- Quadrangles, on faces

- prisms or hexahedrons on volumes, following the type of meshing of the base faces (triangles or rectangles)

Illustration

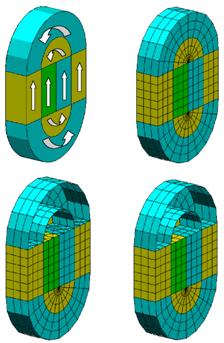

The meshing of a face and of a volume by means of an extrusive mesh generator is illustrated in the figure below.

| Meshing of a face with an extrusive mesh generator defined by a transformation of rotation type | |

|---|---|

|

|

|

| Quadrilateral rectangle | |

| Meshing of a volume by an extrusive mesh generator defined by a transformation of rotation type | |||

|---|---|---|---|

|

|

|

|

|

The mesh is potentially anisotropic and the volume elements are prisms or hexahedrons, depending on the mesh elements of the original face (triangles or rectangles).

Application

The mesh generator is particularly interesting when meshing thin regions (air gaps, thin laminations, skin depth).

It reduces the mesh disturbance effect (noise) on results using the symmetries of the device.

It has an economic effect by reducing the number of nodes necessary to construct the mesh.

Restriction

This mesh generator takes longer and is more difficult to implement than the automatic mesh generator.

2D example

Originally developed to mesh volumes, the extrusive mesh generator can also be assigned to faces.

To obtain an extrusive mesh on faces, a prerequisite is that the face be obtained by extrusion with an existing transformation (rectilinear extrusion by translation, positive ratio affinity, or curvilinear extrusion by rotation).

Example : Extrusive mesh of a quarter circle (Extrusion from the base line by a rotation of 90°)3D Example

Let us consider device below which consists of eight volumes, meshed by extrusion (extrusion by translation for the first four volumes and extrusion by rotation for the other four volumes).

Two different extrusive meshes have been carried out, one with a triangular base, the other with a rectangular base.

On these meshes, one can notice :

- the capacity to mesh while forming a cycle.

- an extrusive mesh in rotation with specific elements near the axis (prisms, tetrahedrons, pyramids).

- the direction of extrusion of low importance