HM-4460: Composite

In this tutorial, you will: mesh all of the surfaces at once; define the dummy properties and assign them to the mesh; define an orientation for the component; use the Ply Realization and distribution table option; laminate realize; create and edit a distribution table; and use the Ply thickness visualization representation option.

Load the ANSYS User Profile

In this step, you will load the ANSYS user profile in HyperMesh.

- Start HyperWorks.

- From the menu bar, click File > Solver Interface > Ansys.

Load the Model

In this step, you will load the model file in HyperMesh

- From the menu bar, click File > Import > Geometry Model.

- In the Import File dialog, select pillar_w_ncf.CATPart.

-

In the Geometry Import Options dialog, click

Import.

Note: You will import the Ply and Composite data later in this tutorial.HyperMesh imports geometry data only.Figure 1.

-

In the Model Browser, review the model contents.

Figure 2.

Mesh all of the Surfaces at Once

In this step, you will mesh all of the model surfaces simultaneously while specifying element sizes and element types.

-

Open the Automesh panel by completing one of the following options:

- From the main panel area, open the 2D page and click automesh.

- Press F12.

- Open the size and bias subpanel.

- Set the entity selector to surfs.

- Click surfs > displayed.

- In the element size= field, enter 5.

- Set mesh type to mixed.

- Set the mesh mode to interactive.

-

Set the elements to surf comp/elements to current comp toggle to

elems to current comp.

Figure 3.

-

Click mesh.

Note: You should now be in the density subpanel of the meshing module. There is node seeding and a number on each surface edge. The number indicates the number of elements that were created along the edge.The meshing module opens.Figure 4.

-

Click return.

The mesh is accepted.Figure 5.

- From the menu bar, click File > Save As > HyperMesh Model.

- In the Save File As dialog, navigate to your working directory and save the HyperMesh database with the name pillar_w_ncf_FINAL.hm.

Load the Ply Information from FiberSim

In this step, you will load the ply information from FiberSim in HyperMesh.

- From the menu bar, click File > Import > Geometry Model.

- In the Import File dialog, select pillar.h5.

-

In the Geometry Import Options dialog, click

Import.

HyperMesh imports and populates the database with laminate data (ply book and ply stacking data), composite material information, each ply data (triangular elements spanning a single ply), and a coordinate system.

-

In the Model Browser, review the model's contents.

Figure 6.

-

In the Model Browser, turn off the display of geometry for

all of the components.

Figure 7.

Review and Edit the Element Normals

In this step, you will review and edit element normals in a model in HyperMesh.

-

From the Elements ribbon, click the Normals tool.

Figure 8.

Note: Element normals need to be changed to match the Z direction (red color).The Normals panel opens.

Note: Element normals need to be changed to match the Z direction (red color).The Normals panel opens. -

Set the first switch to elems as seen in Figure 9.

Figure 9.

- Click elems > displayed.

- Set the vector display/color display toggle to color display.

-

Click display.

Note: The red side of the elements is the positive normal direction Z, while the blue side is the negative normal direction.HyperMesh displays, on each side of the part, the element normals using the colors red and blue.Figure 10.

- Set orientation to elem.

-

Select one element that has the right direction.

This element will be used as the model for the other elements.

-

Click adjust.

All of the elements are set in the same normal direction.

- Optional:

If the blue color is in the Z direction, click elems > displayed and then click reverse.

All of the elements are set in the right normal direction (red).Figure 11.

- Click return to exit the panel.

Realize Ply Geometry Shape

In this step, you will realize the ply geometry shape.

- In the Model Browser, right-click on the Plies folder and select Realize from the context menu.

- In the Ply Realization dialog, click Component.

-

In the graphics area, click the three dots besides the components selector, as

seen in Figure 12.

Figure 12.

-

In the Advanced Selection dialog, select all listed

components.

Figure 13.

- Click OK then click the green check mark.

- Set Projection options to FiberSim drape map by proximity method.

-

Set Search Criterion to Element centroid.

Figure 14.

-

Click Realize.

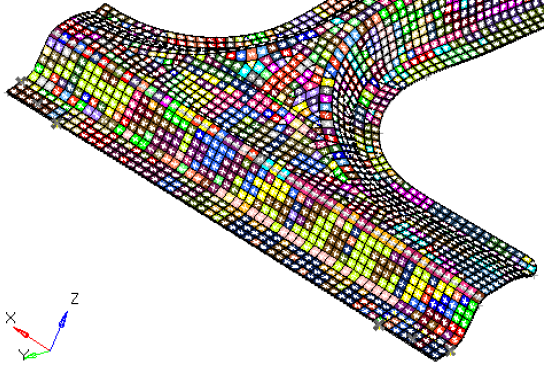

This process takes each FiberSim Ply data and finds the FE elements which are bounded by the ply boundaries, and transfers the ply directions, draping data, and ply orientation into FE elements. This process also converts geometry plies into FE plies. At the end of realization, HyperMesh creates sets containing FE elements for each ply.Figure 15.

Add an Element Type

In this step, you will add an element type.

-

In the Model Browser, right-click and select Create > Sensor from the context menu.

HyperMesh creates and opens a sensor (Et Type).

- In the Entity Editor, enter a name and ID, and select a color.

-

By default, Element Type is set to SHELL181.

- SHELL181

- Suitable for analyzing thin to moderately-thick shell structures. It is a 4-node element with six degrees of freedom at each node: translations in the x, y, and z directions, and rotations about the x, y, and z-axes. (If the membrane option is used, the element has translational degrees of freedom only). The degenerate triangular option should only be used as filler elements in mesh generation.

- Well-suited for linear, large rotation, and/or large strain nonlinear applications. Change in shell thickness is accounted for in a nonlinear analysis. In the element domain, both full and reduced integration schemes are supported. SHELL181 accounts for follower (load stiffness) effects of distributed pressures.

- May be used for layered applications for modeling laminated composite shells or sandwich construction. The accuracy in modeling composite shells is governed by the first order shear deformation theory.

- Optional: If necessary, click View > Solver Browser from the menu bar to open the Solver Browser.

-

In the Solver Browser, review the new element type.

Figure 16.

Define Material Properties

-

In the Model Browser, right-click and select Create > Material from the context menu.

HyperMesh creates and opens a material in the Entity Editor.

- For Name, enter Steel.

- Optional:

For ID, enter a new ID.

Note: By default, HyperMesh sets the ID to 1. If you create a new material, HyperMesh will set the ID to n+1.

- Click the Color icon, and select a color.

-

Set card image to

MATERIAL.

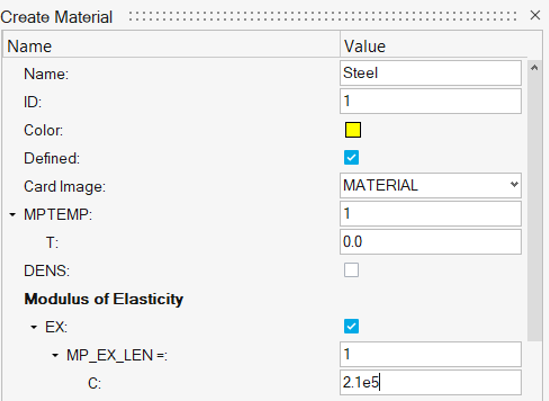

Figure 17.

- Select the EX (Elastic moduli) checkbox.

-

For MP_EX_LEN (Number of Elastic moduli to input), enter

1.

Figure 18.

-

For C, enter 2.1e5.

Figure 19.

- Select the NUXY (Minor Poisson's ratio) checkbox.

- For MP_NUXY_LEN (Number of Minor Poisson's ratio to input), enter 1.

- For C, enter 0.3.

- In the MP_NUXY_LEN= dialog, enter 0.3.

Create the Section Card for the Shell Elements in the Model

-

In the Model Browser, right-click and select Create > Property from the context menu.

HyperMesh creates and opens a property in the Entity Editor.

- For Name, enter SECTl.

- Optional:

For ID, enter a new ID.

Note: By default, HyperMesh sets the ID to 1. If you create another new beam section collector, HyperMesh will set the ID to n+1.

- Click the Color icon and select a new color.

- Set card image to SECTYPE.

-

For MAT, click Unspecified > Material.

Figure 20.

- Click the search icon.

- In the Select Material dialog, select Steel.

- Right-click on SECTION and select Create.

-

In the new Entity Editor, change the config to

Shell, set the Tk value to

0.5, then click Previous.

Figure 21.

- For TYPE, click Unspecified > Sensor.

-

Click the search icon then assign sensor1.

Figure 22.

Update the Component with Property

In this step, you will update the component with the SECTYPE property.

-

In the Component folder of the Model Browser, select

Geometry.

The Entity Editor opens and displays the component's corresponding data.

- For Property, click Unspecified > Property.

- Click the search icon then assign SECT1.

Ply Visualization

In this step you will verify FE plies thickness and orientation in HyperMesh.

-

Set the entity selector in the graphics area to

Properties.

Figure 23.

This automatically colors faces based on their associated properties.

This automatically colors faces based on their associated properties. -

On the View Controls toolbar, click

.

.

-

Set the layer representation mode to Ply layers and

direction.

Figure 24.

-

In the Model Browser, Hide and

Show each Ply.

Figure 25.

Figure 26.

Figure 26.

Laminate Realize the Ply Based Model

In this step, you will laminate realize the ply-based model.

- In the Model Browser, right-click on the Laminate folder and select Realize from the context menu.

-

In the Laminate Realize dialog, accept the default

settings and click Realize.

Figure 27.

HyperMesh creates a property for each stack, and assigns it to a component.

HyperMesh creates a property for each stack, and assigns it to a component. -

Set the entity selector in the graphics area to

Components to change the face coloring.

Figure 28.

- In the Plies Browser, review the number of plies, thickness, orientation, and material data.

Export the Deck to ANSYS *.cdb Format

In this step, you will export the deck to ANSYS *.cdb format.

- Click File > Export > Solver Deck from the menu bar.

-

Set File type to Ansys.

If you are in the ANSYS user profile, HyperMesh automatically sets the File type to Ansys and loads ANSYS as the default Template.

- Navigate to your working directory and save the file as pillar_w_ncf-FINALhm.cdb.

- In the Solver Export Options dialog, click Export.