RD-V: 0030 Spring (TYPE4)

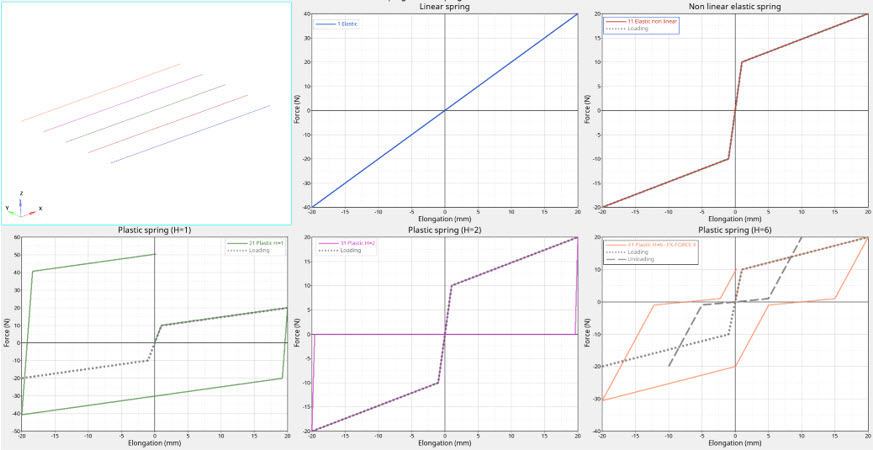

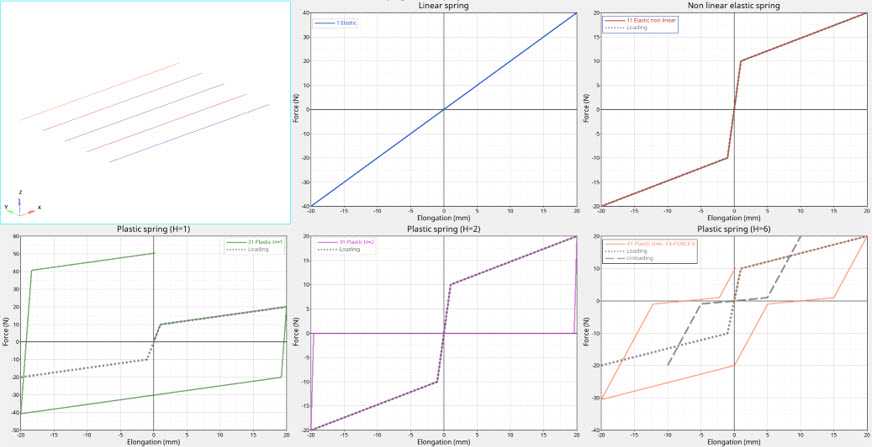

Spring force as function of elongation for different stiffness formulations.

The subject of this study is to verify the behavior of the spring element using different stiffness formulations with a defined elongation.

Options and Keywords Used

Input Files

必要なモデルファイルのダウンロードについては、モデルファイルへのアクセスを参照してください。

Model Description with Different Stiffness Formulation

Units: Mg, s, mm, MPa

- Elastic linear stiffness

- K=2N/mm

- Nonlinear elastic stiffness

- Force versus displacement function:

- Elongation

- Force

- -20

- -20

- -1

- -10

- 0

- 0

- 1

- 10

- 20

- 20

- Linear stiffness K=50N/mm used for transition

- Force versus displacement function:

- Nonlinear plastic stiffness with isotropic hardening

(H=1)

- Same force versus displacement function and same linear stiffness

- Plastic behavior with H=1

- Linear stiffness K=50N/mm used for transition

- Nonlinear plastic stiffness with uncoupled hardening

(H=2)

- Same force versus displacement function and same linear stiffness

- Plastic behavior with H=2

- Linear stiffness K=50N/mm used for transition

- Nonlinear plastic stiffness with nonlinear unloading

(H=6)

- Same force versus displacement function and same linear stiffness

- Nonlinear unloading force versus displacement:

- Elongation

- Force

- -10

- -20

- -5

- -1

- 0

- 0

- 5

- 1

- 10

- 20

- Plastic behavior with H=6

- Linear stiffness K=50N/mm used for transition

Imposed displacement is defined on one end of the spring element to model tensile and compression (displacement +/- 20mm) with constant velocity of 200mm/s.

The other end of the spring element is clamped.

Results

| Time | Elastic Linear Stiffness | Nonlinear Elastic | Nonlinear Plastic Stiffness with Isotropic Hardening (H=1) | Nonlinear Plastic Stiffness with Isotropic Hardening (H=2) | Nonlinear Plastic Stiffness with Nonlinear Unloading (H=6) |

|---|---|---|---|---|---|

| t=0.1s | 40 | 20 | 20 | 20 | 20 |

| t=0.2s | 0 | 0 | -30.10526316 | 0 | -20 |

| t=0.3s | -40 | -20 | -40.63157895 | -20 | -30.52631579 |

| t=0.4s | 0 | 0 | 50.30249307 | 0 | 9.473684211 |

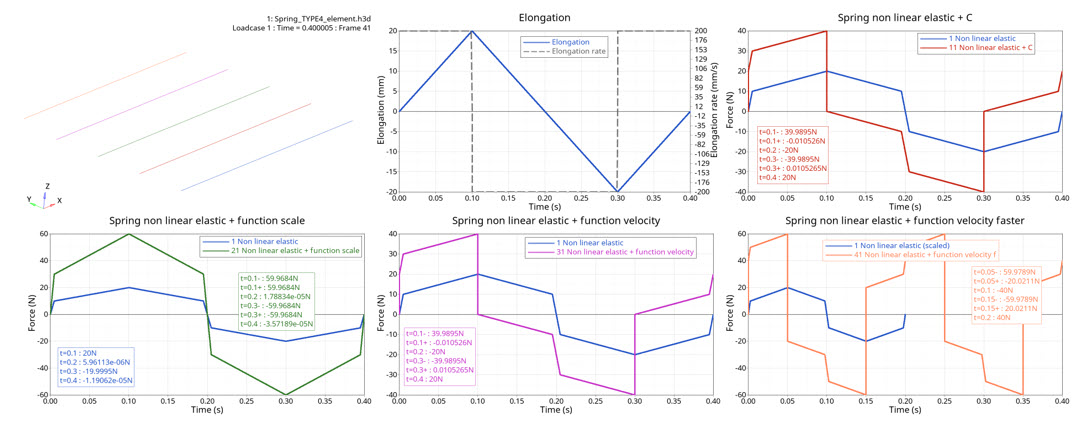

Model Description with Behavior at Different Deformation Rates

Units: Mg, s, mm, MPa

- Nonlinear elastic stiffness

- Force versus elongation function:

- Elongation

- Force

- -20

- -20

- -1

- -10

- 0

- 0

- 1

- 10

- 20

- 20

- Force versus elongation function:

- Elongation rate dependency

- Linear value

- Stiffness scale factor

- Force versus elongation rate scale factor function:

- Elongation Rate

- Force

- -10

- 0.1

- 0

- 0

- 10

- 0.1

- Damping versus elongation rate function

- Elongation Rate

- Damping

- -10

- -1

- 0

- 0

- 10

- 1

- Damping versus elongation rate function with higher velocity

The imposed displacement function abscissa (time) is scaled by 0.5 to double the constant loading velocity.

Imposed displacement is defined on one end of the spring element to model tension and compression (displacement +/- 20mm) with constant velocity of 200mm/s (with abscissa scale factor 1.0) or 400mm/s (with abscissa scale factor 0.5).

The other end of the spring element is clamped.

Results

| Time | Nonlinear Elastic | Nonlinear Elastic + C | Nonlinear Elastic + Velocity-based Force Function Scale | Nonlinear Elastic + Velocity-based Damping Function (200 mm/s) | Nonlinear Elastic + Velocity-based Damping Function (400 mm/s) |

|---|---|---|---|---|---|

| t=0.1s (V+) | 20 | 40 | 60 | 40 | 60 |

| t=0.1s (V-) | 20 | 0 | 60 | 0 | -20 |

| t=0.2s (V-) | 0 | -20 | 0 | -20 | -40 |

| t=0.3s (V-) | -20 | -40 | -60 | -40 | -60 |

| t=0.3s (V+) | -20 | 0 | -60 | 0 | 20 |

| t=0.4s (V+) | 0 | 20 | 0 | 20 | 40 |

Conclusion

The Radioss computation returns results very close to the theoretical values with the expected behavior for the different elastic, plastic behavior and with deformation rate formulations.