Model Setup and Baseline Analysis

The following set of steps completes the analysis setup of the initial model and provides a baseline analysis for comparison with the final optimized structure.

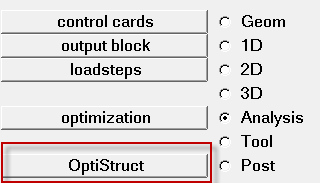

Launch HyperMesh and Set the OptiStruct User Profile

Open the Model

Set Up the Model

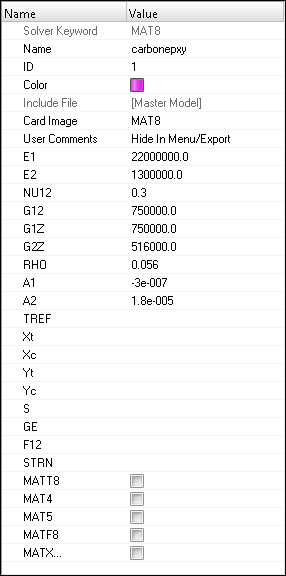

Create Carbon Epoxy Material

Create Element Set

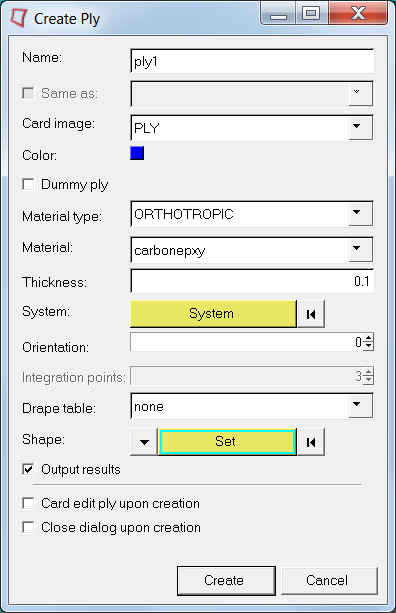

Create Basic Plies

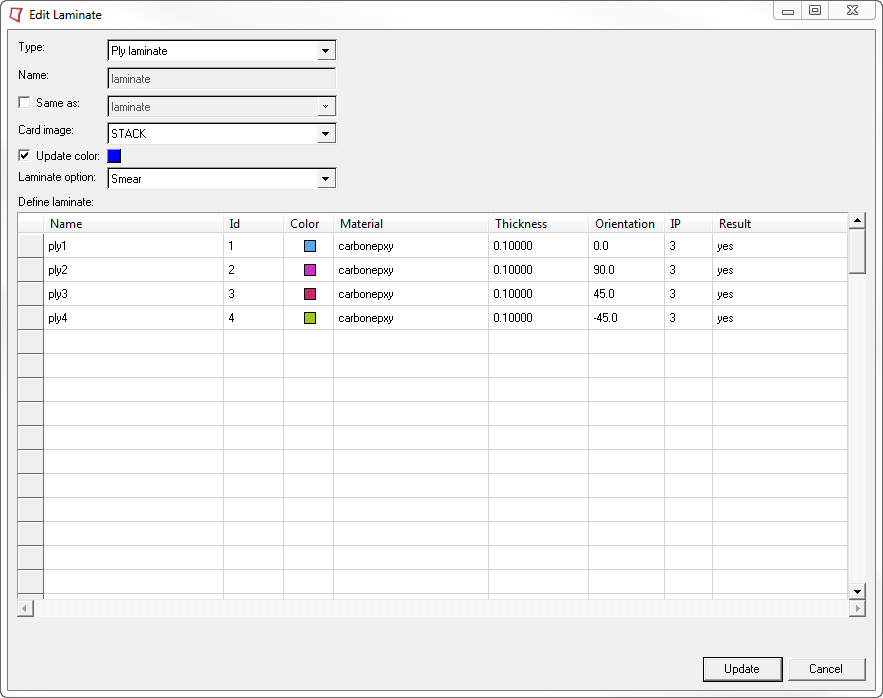

Create Laminate

Create and Assign a Property

-

Create the property, laminate_property.

-

Assign elements to the property, laminate_property.

- In the Model Browser, Properties folder, right-click on laminate_property and select Assign from the context menu.

- In the panel area, use the elems selector to select all elements in the model.

- Click proceed.

Review the Model

Create Output Requests

Submit the Job

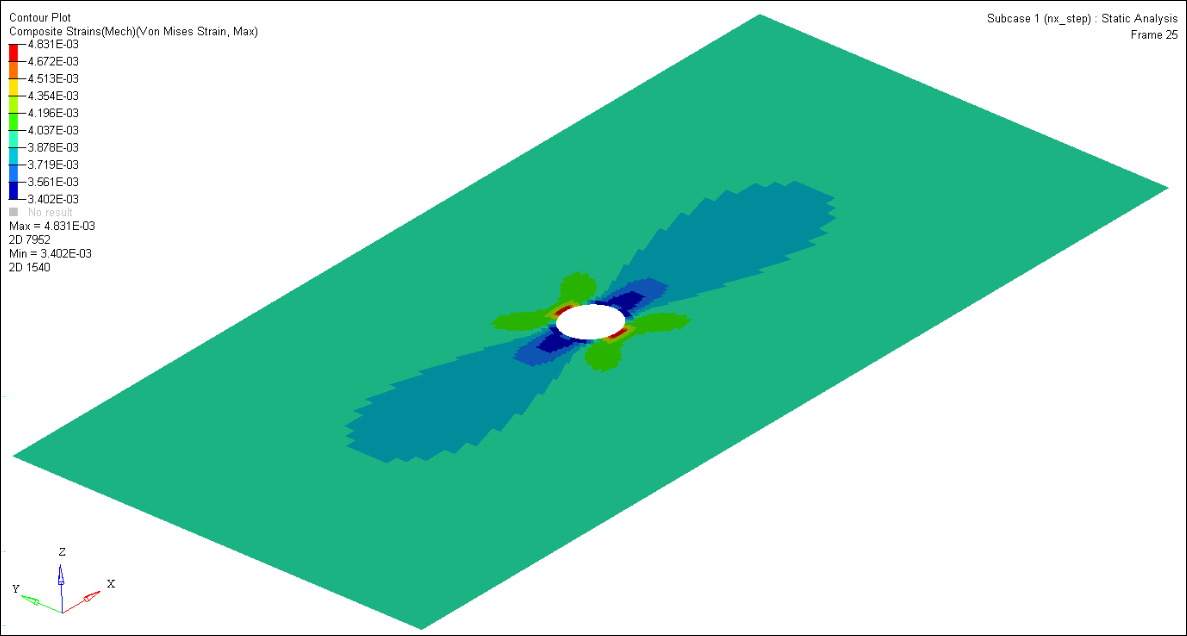

View the Results

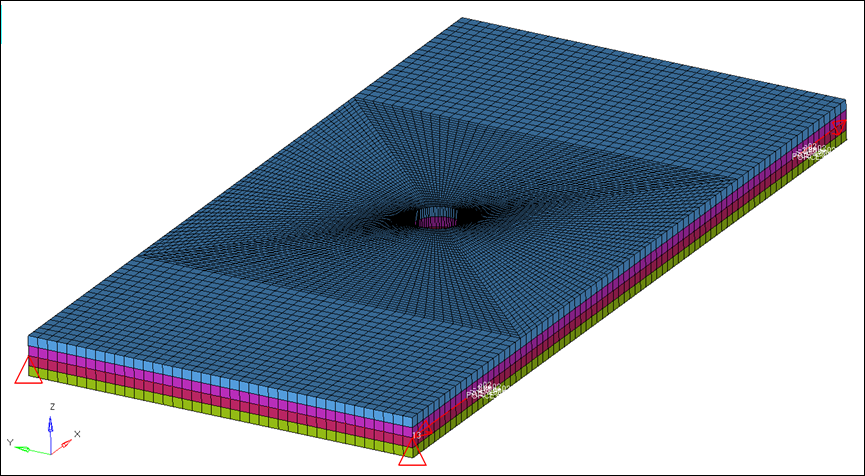

Figure 6.

Deactivate the Composite Visualization Enhancements

-

On the Page Controls toolbar, click

to close the HyperView session and return to the

HyperMesh client.

to close the HyperView session and return to the

HyperMesh client.

-

On the Visualization toolbar, change the visualization settings.

- Set the element visualization mode to 2D Traditional Element Representation.

- Set the layers mode to Layers Off.

- Set the element color mode to By Comp.

to set the

element visualization mode to

to set the

element visualization mode to  to set the

layers mode to

to set the

layers mode to

to open the

to open the