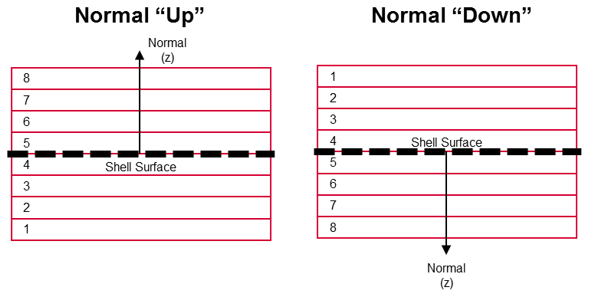

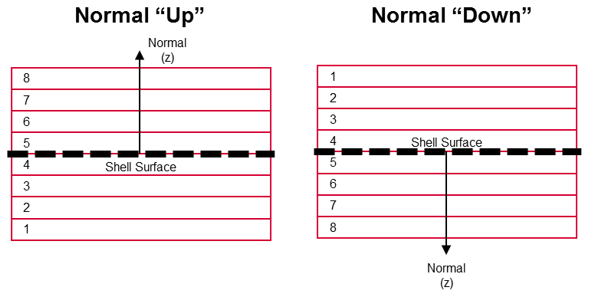

Stack Direction

Stacking direction of plies in a laminate.

The stacking direction of plies in a laminate is determined by element normals for both ply-based and zone-based models. Element normals can be set from either the or panels.

Figure 3.

Stacking direction of plies in a laminate.

The stacking direction of plies in a laminate is determined by element normals for both ply-based and zone-based models. Element normals can be set from either the or panels.