Create Midmesh

Use the Midmesh: Automatic tool to automatically generate a mesh at the midplane location, directly from the input geometry (components, elements, solids or surfaces), without first creating a midsurface. This saves significant time over the traditional midsurface-based approach.

Options for Creating Midmesh

Access the following options by clicking ![]() on the

Midmesh: Automatic tool guide bar.

on the

Midmesh: Automatic tool guide bar.

- Edit criteria

- Set the minimum size and target element size settings in the criteria file to control the resulting midmesh via the Criteria File Editor.

- Extraction size

- The midmesh extraction element size. By default this is taken as the target element size from the criteria file. This can be set smaller than the target size, though that is not recommended unless there are problems extracting at the target size.

- Minimum size

- Minimum element size allowed in the finalized mesh. This in combination

with the ‘suppress proximity edges factor’ and 'combine non-manifold

edges factor’ can ensure that the output mesh is ready for rebuild with

the same criteria.

Can only be modified in the Criteria File Editor.

- Mask input entities

- Hide input midmeshed entities in the modeling window upon exiting the context.

- Destination component

- Select which component newly created midmeshes are placed in.

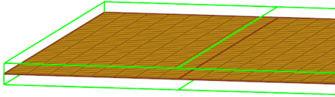

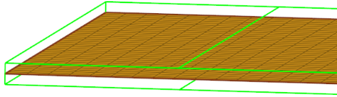

- Ignore flat edges

- Do not imprint flat edges from the input geometry onto the

midmesh.

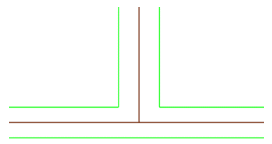

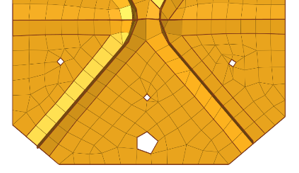

Figure 2. Option Off

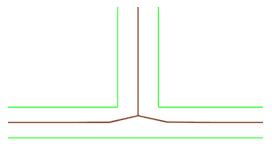

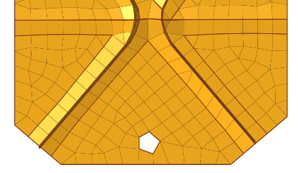

Figure 3. Option On - Flatten connections

- Aligns/flattens the midmesh at ribs/connections.

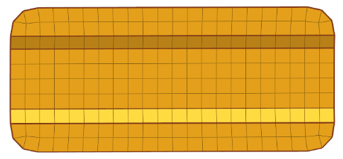

Figure 4. Option Off

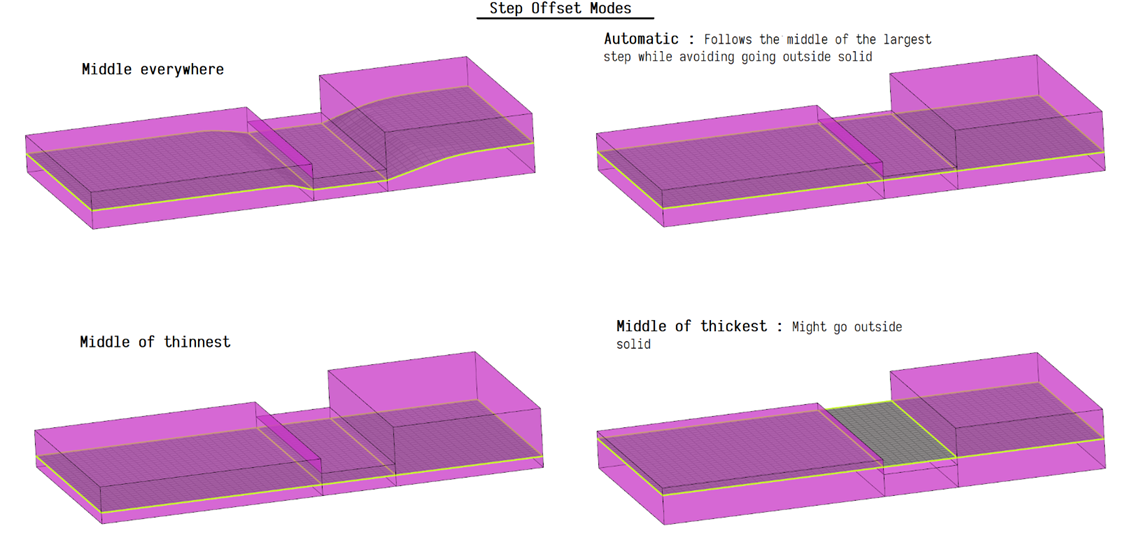

Figure 5. Option On - Step offset mode

- This option allows finer control of how stepped geometry (one side continuous surface, and opposite side steps) is captured. This option is valid only when flatten connections is enabled. Values can be:

- Suppress proximity edges factor

- The minimum size factor for removing edges within proximity. Edges

closer than this factor times minimum size will be

suppressed.

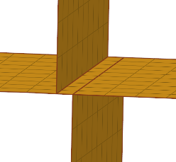

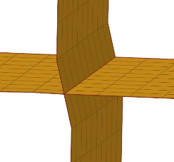

Figure 7. Option Off

Figure 8. Option On - Combine non-manifold edges factor

- The minimum size factor for joining non-manifold edges. Non-manifold

edges closer than this factor times minimum size will be

combined.

Figure 9. Option Off

Figure 10. Option On - Defeature ribs width factor

- The minimum size factor for removing small ribs. Ribs closer than this factor times minimum size will be suppressed. Default is 0.9.

- Defeature openings with width <

- The maximum width for removal of small holes and openings.

Figure 11. Option Off

Figure 12. Option On

to define midmesh

options.

to define midmesh

options.