/FAIL/HASHIN

Block Format Keyword Describes the Hashin failure model. This failure model is available for Shell and Solid.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /FAIL/HASHIN/mat_ID/unit_ID | |||||||||

| Iform | Ifail_sh | Ifail_so | ratio | I_Dam | Imod | I_frwave | |||

| Sdel | Tcut | ||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| Soft | |||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fail_ID |

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier (Integer, maximum 10 digits) |

|

| Iform | Formulation flag.

(Integer) |

|

| Ifail_sh | Shell failure flag.

(Integer) |

|

| Ifail_so | Solid failure flag.

(Integer) |

|

| ratio | For

Isolid=2 or

Ifail_sh=2: the

element will be deleted, if more than ratio of the layers (or integration points)

have failed. Default = 1.0 (Real) |

|

| I_Dam | Damage calculation flag. 6

(Integer) |

|

| Imod | Relaxation time calculation.

(Integer) |

|

| I_frwave | Failure propagation flag between neighbor elements.

(Integer) |

|

| Low strain rate limit. Default = 0.0 (Real) |

||

| Longitudinal tensile strength (in fiber direction). Default = 1020 (Real) |

||

| Transverse tensile strength (perpendicular to the fiber direction). Default = 1020 (Real) |

||

| Through thickness tensile strength. Default = 1020 (Real) |

||

| Longitudinal compressive strength (in fiber direction). Default = 1020 (Real) |

||

| Transverse compressive strength (perpendicular to the fiber direction). Default = 1020 (Real) |

||

| Crush strength. Default = 1020 (Real) |

||

| Fiber shear strength. Default = 1020 (Real) |

||

| Matrix shear strength 12. Default = 1020 (Real) |

||

| Matrix shear strength 23. Default = 1020 (Real) |

||

| Matrix shear strength 13. Default = 1020 (Real) |

||

| Coulomb friction Angle for matrix and

delamination < 90 degrees. Default = 0 (Real) |

||

| Sdel | Delamination criteria scale factor. Default = 1.0 (Real) |

|

| Dynamic time relaxation. 5 Default = 1020 (Real) |

||

| Reference strain rate. Default = 10-20 (Real) |

||

| Tcut | Strain rate cutoff period. Default = (Real) |

|

| Soft | Reduction factor applied to failure criteria when

one of neighbor elements has already

failed. Only used if, I_frwave=2. 0.0. ≤ Soft ≤ 1.0 Default = 0.0 (Real) |

|

| fail_ID | (Optional) Failure criteria identifer. 4 (Integer, maximum 10 digits) |

Example (Composite)

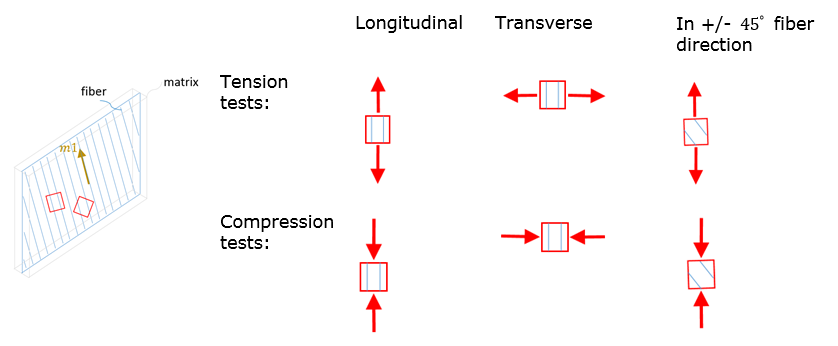

Figure 1. Fabric Lamina Model (Iform =2)

#RADIOSS STARTER

/UNIT/1

unit for mat and failure

# MUNIT LUNIT TUNIT

kg mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/COMPSH/1/1

composite material

# RHO_I

1.5E-6

# E11 E22 NU12 Iform E33

42 40 .05 1 .5

# G12 G23 G31 EPS_f1 EPS_f2

3.4 3 3 0 0

# EPS_t1 EPS_m1 EPS_t2 EPS_m2 dmax

0 0 0 0 .9999

# Wpmax Wpref Ioff IFLAWP ratio

0 0 5 0 0

# c EPS_rate_0 alpha ICC_global

0 2E-4 0 1

# sig_1yt b_1t n_1t sig_1maxt c_1t

.1 25 .1 0 0

# EPS_1t1 EPS_2t1 SIGMA_rst1 Wpmax_t1

0 0 0 0

# sig_2yt b_2t n_2t sig_2maxt c_2t

.1 20 .1 0 0

# EPS_1t2 EPS_2t2 sig_rst2 Wpmax_t2

0 0 0 0

# sig_1yc b_1c n_1c sig_1maxc c_1c

.005 800 .5 0 0

# EPS_1c1 EPS_2c1 sig_rsc1 Wpmax_c1

.08 .15 .1 0

# sig_2yc b_2c n_2c sig_2maxc c_2c

.005 2000 .5 0 0

# EPS_1c2 EPS_2c2 sig_rsc2 Wpmax_c2

0 0 0 0

# sig_12yt b_12t n_12t sig_12maxt c_12t

.004 83 .31 0 0

# EPS_1t12 EPS_2t12 sig_rst12 Wpmax_t12

.075 .085 .05 0

# GAMMA_ini GAMMA_max d3max

1E31 1E31 .9999

# Fsmooth Fcut

0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FAIL/HASHIN/1/1

# Iform Ifail_sh Ifail_so Ratio I_Dam Imod Ifrwave EPS_DOT_MIN

2 1 0 0 1

# Sigma1_T Sigma2_T Sigma3_T Sigma1_C Sigma2_C

2 .525 1E30 1.7 1.7

# Sigma_C SigmaF_12 SigmaM_12 SigmaM_23 SigmaM_13

1E30 1E30 .075 1E30 1E30

# Phi Sdelam Tau_max EPS_DOT_0 Tcut

0 1 .01

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#enddata

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- Example of ratio: if ratio=0.5, and Ifail_sh=2 (or Ifail_so=2), the element will be deleted, if more than half of the layers (or integration points) failed.

- The 3D material failure model:

- Uni-directional lamina model:Tensile/shear fiber mode:

(1) Compression fiber mode:(2) with,

Crush mode:(3) with,

Failure matrix mode:(4) Delamination mode:(5) Where,

Note:(6) - Fabric lamina model:Tensile/shear fiber mode:

(7) (8) With

Compression fiber mode:(9) with,(10) with,

Crush mode:(11) with,

Shear failure matrix mode:(12) Matrix failure mode:(13) Where,

If the damage parameter is Fi ≥ 1.0, the stresses are decreased by using an exponential function to avoid numerical instabilities. A relaxation technique is used by decreasing the stress gradually:(14) With,(15) and

Where,- Time

- Start time of relaxation when the damage criteria is assumed

- Time of dynamic relaxation

- Stress at the beginning of damage

- Uni-directional lamina model:

- The damage value, D is 0 ≤ D ≤ 1. The

status for fracture is:

- Free, if 0 ≤ D > 1

- Failure, if D=1

with for uni-directional lamina model and for fabric lamina model. This damage value shows with /ANIM/BRICK/DAMA or /ANIM/SHELL/DAMA.

- The fail_ID is used with /STATE/BRICK/FAIL and /INIBRI/FAIL. There is no default value. If the line is blank, no value will be output for failure model variables in the /INIBRI/FAIL (written in .sta file with /STATE/BRICK/FAIL option).

- After the failure criterion is reached, the value determines a period of time when the stress in the failed element is gradually reduced to zero. When the stress reaches 1% of the stress value at the start of failure, the element is deleted. This is necessary to avoid instabilities coming from a sudden element deletion and a failure “chain reaction” in the neighboring elements. Even if the failure criterion is reached, the default value of results in no element deletion. Therefore, it is recommended to define 10 times larger than the simulation time step.

- The I_Dam option improves damage calculation and stability calculating damage.