/MAT/LAW110 (VEGTER)

Block Format Keyword Elasto-plastic constitutive law using the interpolated yield criterion of Corus-Vegter and the hardening law of Vegter, accounting for strain rate dependency and thermal effect.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW110/mat_ID/unit_ID or /MAT/VEGTER/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | v | Ires | |||||||

| TAB_YLD | MAT_Xscale | MAT_Yscale | |||||||

| Tini | Chard | Fcut | VP | Ismooth | TAB_TEMP | ||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| R | |||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| R | |||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| R | |||||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Optional unit identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material title. (Character, maximum 100 characters) |

|

| Initial density. (Real) |

||

| E | Young‘s modulus. (Real) |

|

| v | Poisson's ratio. (Real) |

|

| Ires | Return mapping algorithm flag.

(Integer) |

|

Vegter formulation selection:

(Integer) |

||

| TAB_YLD | Tabulated yield stress – plastic strain - strain rate

function identifier. (Integer) |

|

| MAT_Xscale | X scale factor of the tabulated yield – plastic strain -

strain rate function. Default = 10 (Real) |

|

| MAT_Yscale | Y scale factor of the tabulated yield – plastic strain -

strain rate function. Default = 1.0 (Real) |

|

| Biaxial scale factor. (Real > 0.0) |

||

| Biaxial strain rate ratio in the 0 degree direction with

respect to RD. (Real > 0.0) |

||

| Initial yield stress. (Real) |

||

| Hardening stress increment. (Real) |

||

| Large strain hardening parameter. (Real) |

||

| Small strain hardening parameter. (Real) |

||

| Hardening exponent. (Real) |

||

| Initial plastic strain. (Real) |

||

| Limit dynamic flow stress. (Real) |

||

| Maximum activation enthalpy. (Real) |

||

| Limit strain rate for thermal activated

movement. (Real) |

||

| Strain rate behavior exponent. (Real) |

||

| Tini | Initial temperature. (Real) |

|

| Chard | Hardening coefficient.

(Real) |

|

| Fcut | Cutoff frequency for strain rate filtering. Default = 1.0 x 1020 (Real) |

|

| VP | Strain rate choice flag.

(Integer) |

|

| Ismooth | Interpolation type (in case of tabulated yield function).

(Integer) |

|

| TAB_TEMP | Tabulated yield stress – plastic strain – temperature

identifier. (Integer) |

|

| Uniaxial scale factor. (Real > 0.0) |

||

| R | Lankford coefficient. Default = 1.0 (Real > 0.0) |

|

| First component of the plane strain scale factor. (Real > 0.0) |

||

| Second component of the plane strain scale factor (

= 1). (Real > 0.0) |

||

| Average factor to compute the second component of the plane

strain scale factor (

= 2). Default = 0.5 (Real > 0.0) |

||

| Shear scale factor. (Real > 0.0) |

||

| Maximum uniaxial engineering stress for the direction at

degree with respect to the

rolling direction (RD) (

= 3). (Real > 0.0) |

||

| Maximum uniaxial uniform elongation in % for the direction at

degree with respect to the

rolling direction (RD) (

= 3). (Real > 0.0) |

||

| Lankford coefficient for the direction at

degree with respect to the

rolling direction (RD) (

= 3). Default = 1.0 (Real > 0.0) |

||

| Plane strain weight factor (

= 4). (Real > 0.0) |

||

| Shear weight factor (

= 4). (Real > 0.0) |

Examples

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/25

Local unit system

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW110/1/25

Steel: Icrit = 1, example with 3 angles (0°, 45° and 90° to the RD)

# Init. dens.

7.85E-9

# E nu

194200.0 0.3

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

# Icrit TAB_YLD MAT_Xscale MAT_Yscale fBI rhoBI

1 0 0.0 0.0 1.004 0.889

# YLD0 DSIGM BETA OMEGA n

107.1 179.6 0.25 8.07 1.0

# EPS0 SIGS DG0 Deps0 m

0.0 20.0 800 3.61e-3 1.0

# TINI C_HARD F_CUT VP Ismooth TAB_TEMP

293.0 0.0 10000.0 1 1 0

# fUN_THETA R_THETA fPS1_THETA fPS2_THETA fSH_THETA

1.021 0.64 1.061 0.5305 0.560

0.987 0.48 1.037 0.5185 0.640

1.009 0.76 1.048 0.5240 0.560

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW110/2/25

Steel :Icrit = 2, example with 3 angles (0°, 45° and 90° to the RD)

# Init. dens.

7.85E-9

# E nu

194200.0 0.3

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

# Icrit TAB_YLD MAT_Xscale MAT_Yscale fBI rhoBI

2 0 0.0 0.0 1.004 0.889

# YLD0 DSIGM BETA OMEGA n

107.1 179.6 0.25 8.07 1.0

# EPS0 SIGS DG0 Deps0 m

0.0 20.0 800 3.61e-3 1.0

# TINI C_HARD F_CUT VP Ismooth TAB_TEMP

293.0 0.0 10000.0 1 1 0

# fUN_THETA R_THETA fPS1_THETA ALPS_THETA fSH_THETA

1.021 0.64 1.061 0.5 0.560

0.987 0.48 1.037 0.5 0.640

1.009 0.76 1.048 0.5 0.560

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW110/3/25

Steel

# Init. dens.

7.85E-9

# E nu

194200.0 0.3

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

# Icrit TAB_YLD MAT_Xscale MAT_Yscale fBI rhoBI

3 0 0.0 0.0 1.004 0.889

# YLD0 DSIGM BETA OMEGA n

107.1 179.6 0.25 8.07 1.0

# EPS0 SIGS DG0 Deps0 m

0.0 20.0 800 3.61e-3 1.0

# TINI C_HARD F_CUT VP Ismooth TAB_TEMP

293.0 0.0 10000.0 1 1 0

# RM_0 RM_45 RM_90 AG_0 AG_45

408.4 408.4 408.4 20.0 20.0

# AG_90 R_0 R_45 R_90

20.0 0.64 0.48 0.76

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW110/4/25

Steel :example with 3 angles (0°, 45° and 90° to the RD)

# Init. dens.

7.85E-9

# E nu

194200.0 0.3

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

# Icrit TAB_YLD MAT_Xscale MAT_Yscale fBI rhoBI

4 0 0.0 0.0 1.004 0.889

# YLD0 DSIGM BETA OMEGA n

107.1 179.6 0.25 8.07 1.0

# EPS0 SIGS DG0 Deps0 m

0.0 20.0 800 3.61e-3 1.0

# TINI C_HARD F_CUT VP Ismooth TAB_TEMP

293.0 0.0 10000.0 1 1 0

# fUN_THETA R_THETA W_PS W_SH

1.021 0.64 0.4125 0.75

0.987 0.48 0.4125 0.75

1.009 0.76 0.4125 0.75

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#enddataComments

- If

= 1, the law uses the

classic Vegter yield criterion which is defined by:

(1) Where,- Yield function.

- Yield stress.

- Interpolated Vegter equivalent stress.

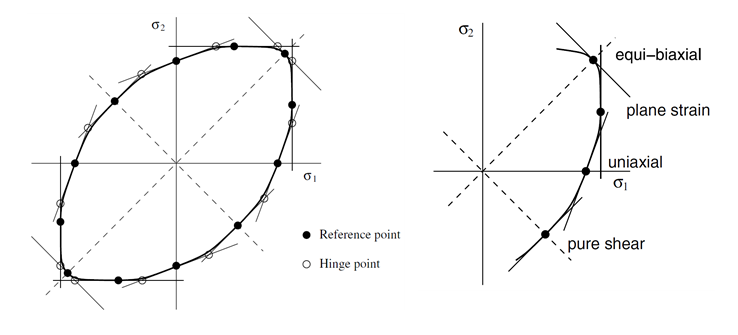

The Vegter yield locus, under plane stress conditions, is obtained by defining three second order Bezier interpolation curves in the principal stresses space (Figure 1).

Figure 1. Yield criterion defined by the classic Vegter formulation in plane-stress (Icrit=1)These curves are used to link four reference points which are measured experimentally at different loading conditions: shear, uniaxial tension, plane strain, and equibiaxial tension. Between two reference points, the yield locus is then defined in:(2) Where,- ,

- Two reference points.

- Hinge point, which is computed automatically.

- Parameter computed at each time step to determine the position on the yield locus.

The four measured reference points are referred to as: , , , and . The coordinates of these reference points are provided by you.

Where, = , , . For a given direction with respect to the rolling direction, only one component must be set for the shear , uniaxial tension , and equibiaxial tension reference point . For the plane-strain reference point, the two components and must be provided by you.

There is a freedom on the choice of the second coordinate . If it is not set, its value will be taken as an average of the second coordinates of the two neighboring hinge points.

The hinge point located between two reference points is computed using the reference points coordinates, but also the normal to the yield surface in each reference point. Using the normality rule, the normal to the yield surface can be expressed using the strain rate tensor component:(3) Where, is the strain rate ratio in a given reference point. For the shear reference point, . For the plane-strain reference point, . For the uniaxial tension reference point, this ratio can be computed from the Lankford coefficient denoted :(4) The Lankford coefficient must be provided by you. Finally, the strain rate ratio in the equibiaxial tension must also be set.

- If

= 2, the standard Vegter

criterion is used. It is the same criterion as the classical Vegter, with a

different input card. In this card, the second coordinate of the plane

strain point is computed as a weighted average of the second coordinate of

the two neighboring hinge points

and

:

(5) - If = 3, the Vegter 2017 yield criterion is used. It is the same criterion as the classical Vegter, with a different input card. In this card, all parameters are determined from the maximum uniaxial engineering stress , the maximum uniform elongation , and the Lankford coefficient . These three parameters must be given for three directions at an angle degrees with respect to the rolling direction RD: 0 degrees, 45 degrees, and 90 degrees. For this criterion, the number of angles is locked at 3.

- If

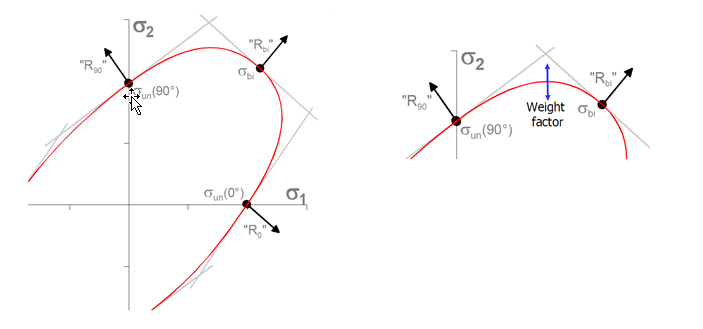

= 4, the law uses the

simplified Vegter Lite yield criterion which is defined by:

(6) Where,- Yield function.

- Yield stress.

- Interpolated Vegter equivalent stress.

The Vegter yield locus, under plane stress conditions, is obtained by defining two second order Nurbs interpolation curves in the principal stresses space. These curves are used to link three reference points which are measured experimentally at different loading conditions: uniaxial compression, uniaxial tension, and equibiaxial tension. Between two reference points, the yield locus is then defined in:(7) (8) Where,- ,

- Two reference points.

- Hinge point, which is computed automatically.

- Parameter computed at each time step to determine the position on the yield locus.

- Weight factor associated with the hinge point.

Figure 2. Yield criterion defined by the classic Vegter formulation in plane-stress (Icrit=2)In Figure 2, yield criterion is defined by the classic Vegter formulation in plane-stress ( = 2).

As for the classical Vegter formulation, you must set the parameters , , , and . In this simplified formulation, the two hinge points are in pure shear and plane strain condition. The two associated weight factors and must also be defined.

- To take into account the anisotropy, you can define a set of parameters for

several

directions at different angle

with respect to the rolling direction RD. These directions must be

equally distributed between 0 and

. For all loading directions that are located

between the given directions, the Vegter model proposes to use a Fourier

series interpolation.Not all parameters must be defined for each direction. The parameter is uniform among all the directions. The strain rate ratio in the direction 0 (rolling direction) is sufficient to determine this ratio for all other directions:

(9) For all other parameters, the following Fourier interpolation is used:(10) In the case of the classic, standard, and 2017 Vegter formulation ( = 1, 2, 3), a similar operation is used.(11) In the case of the simplified Vegter Lite formulation ( = 4), a similar interpolation is used on , , and . In this case:(12) - Parameters must define a convex yield locus, otherwise the simulation might be unstable. That is why a data check is present in the Radioss Starter to check the yield criterion convexity.

- When only one direction is defined, = 1, the material law is isotropic and must be used with /PROP/TYPE1 (isotropic shell). If more than 1 direction is defined, > 1 or = 3, the material law becomes anisotropic and must be used with /PROP/TYPE9 (orthotropic shells).

- The yield stress

is defined by the following expression:

(13) Where,- Initial yield stress.

- Hardening stress increment.

- Large strain hardening parameter.

- Initial plastic strain.

- Small strain hardening parameter.

- Hardening exponent.

- Limit dynamic flow stress.

- Boltzmann constant.

- Temperature.

- Maximum activation enthalpy.

- Inviscid limit strain rate.

- Strain rate dependence exponent.

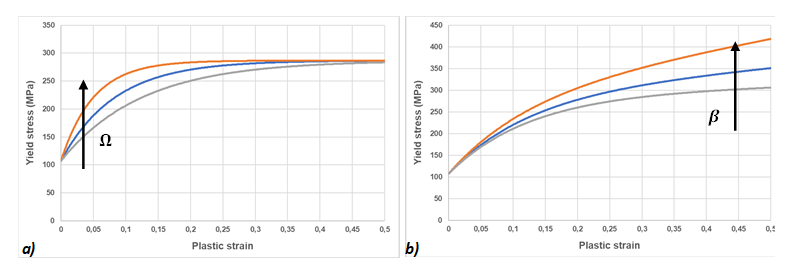

The parameter, is called small strain hardening parameter, as its effect has a strong influence on the hardening curve at small strain (Figure 3a). Similarly, the large strain hardening parameter has a bigger influence at large strain (Figure 3b).

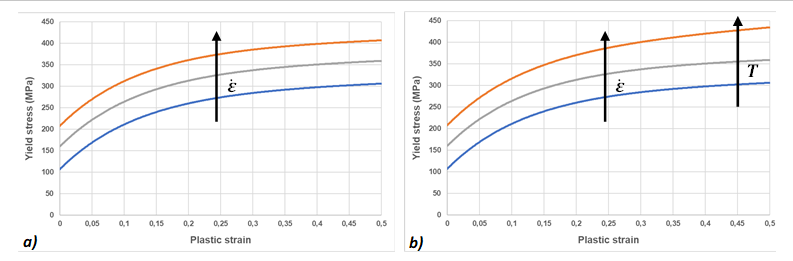

Figure 3. Effect of hardening parameter on the yield stress evaluation - If Tini is defined, the temperature will be constant at the Tini value over the simulation. This will enable a constant strain rate

dependency (Figure 4a).If you want to compute a temperature evolution to take into account the thermal activation effect (slight increase of strain rate dependency following the increase of the temperature), the option /HEAT/MAT must be defined (Figure 4a).

Figure 4. Effect of temperature setting on the strain rate dependency - The strain rate

computation depends on the value of the flag

:

- If = 1: the plastic strain rate is used.

- If = 2: the total strain rate is used.

- If = 3: the deviatoric strain rate is used.

In all cases the strain rate computation includes a filtering, using the cutting off frequency , which is user-defined, such that:(14) With .

- If you want to use a tabulated hardening yield stress, the ID of the

tabulated function TAB_YLD must be defined. This table

can be used to define several yield stress evolutions with the plastic

strain, at several strain rates. Two scale factor can be also defined in the

X and Y directions. In this case, the hardening parameters

,

,

,

, and

are ignored, and the yield stress

becomes:

(15) Furthermore, you can also define a tabulated yield stress with plastic strain and temperature TAB_TEMP, to consider the thermal softening in adiabatic condition. In this case, the yield stress becomes:(16) Where,- Tini

- Reference temperature.

- Actual temperature computed using the /HEAT/MAT option.

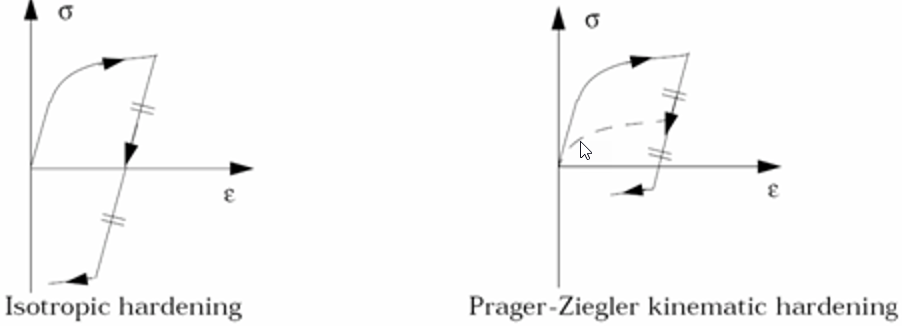

- You might also want to use a kinematic hardening by setting coefficient Chard:

- If Chard = 0: the isotropic hardening is used.

- If Chard = 1: the Prager-Ziegler kinematic hardening is used.

- If 0 ≤ Chard ≤ 1: the model is interpolated between the

isotropic and the kinematic hardening.

Figure 5.