Batch Create Assembly

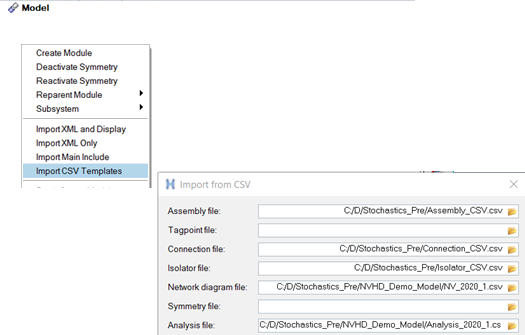

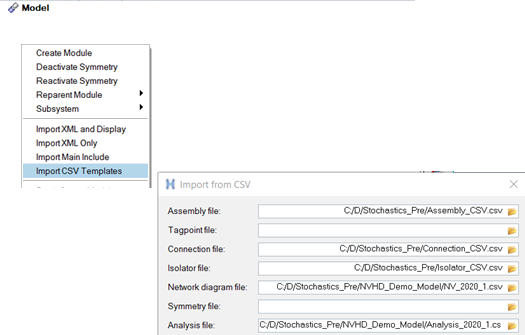

Create a complete vehicle assembly using external .csv files for assembly, tagpoints, connections, isolator, network diagram, symmetry and analysis.

Figure 1.

View new features for Engineering Solutions 2022.3.

Engineering Solutions is a modeling and visualization environment for NVH, Squeak and Rattle Director, Crash, CFD, and Aerospace using best-in-class solver technology.

Discover Engineering Solutions functionality with interactive tutorials.

Noise, Vibration and Harshness (NVH) is an important vehicle attribute that directly affects the customer experience.

Full vehicle NVH represents the most sophisticated form of NVH analysis, with many important benefits.

NVH Director offers the following features for modularized management of vehicle subsystems.

OptiStruct offers many features that reduce solution time and simulation complexities.

A big challenge in full vehicle NVH simulation is handling large size finite element models.

NVH analysis is a special form of physical analysis where the understanding of motion, energy and force transfer are the primary means of root cause identification and problem solving.

The Assembly Browser is an object-oriented modeling environment where the fundamental entity is the module entity.

Allows symmetric creation of LP Modules, Connections and dynamic LCS.

Allows you to change the assembly hierarchy by cutting or pasting the modules.

Set parent modules with CMS SE representation in H3D format to be used for analysis in lieu of child module representations when rolled up, or use the child representations when rolled down.

Select and define a set of modules as the subsystem used for analysis.

To manage any of the modules shown in the Assembly Browser, right-click on a module and select Edit Representations. This opens the Edit Module tab, and the Representation sub-tab is shown.

Create a complete vehicle assembly using external .csv files for assembly, tagpoints, connections, isolator, network diagram, symmetry and analysis.

Create assembly hierarchy and assign ID ranges to the modules from external .csv files.

Reduces the amount of manual work involved in preparing a large number of modules by batch.

Allows automated mapping/creation of tagpoints and connections between data from different sources.

Connections can be created using the Create Connection-Interactive and Create Connection-Automatic tools.

Once the connections have been created, use the Connector Browser to review the connections.

Connections can be managed by right-clicking on a connector in the Connector Browser and selecting Edit Connection.

Use this tool for connection, property and hardpoint mapping.

Use the Connection Realization tool for realization of selected connections based on the specified Tolerance, Property state and State rule.

Manage local coordinate systems (LCS) created in the Assembly framework.

Create defined response points that will be automatically used in setting up output requests in NVH analysis.

Create standard analysis frequency sets that will be automatically used in setting up analysis frequencies in NVH analysis.

Create defined control volumes that will be automatically used in setting up Transfer Path Analysis diagnostic output in NVH analysis.

Create panel sets by selecting nodes/elements and/or existing node sets in the model file, that will automatically be used in setting up Panel Participation diagnostic output in NVH analysis.

In a real-life application, necessary preparation work needs to be done to get the module representation files to a state that is ready for assembly. Use the Prepare Module tool to accomplish this goal.

Edit and test NVH templates used for creating lumped parameter (LP) models, multiple instances of one model transformed to a new geometric location, or loadcases.

An Analysis is a collection of model configuration, analysis loadcase and analysis set-up selections that completely specifies the assembly definition for a particular loadcase simulation event.

Reduce the amount of manual work involved in performing a normal modes run to check out multiple modules by batch processing.

Reduce the amount of manual work involved in generating CMS superelements or CDS superelements for multiple modules by batch processing.

Job Manager is designed to provide a way to interact with analysis jobs created through the NVH Director.

The network view is a block diagram view emphasizing inter-connectivity of the assembly.

Allows for quick comparison of Main solver decks generated from the Analysis Manager or existing Main solver decks.

Allows automatic mapping of modified and/or missing file paths and folders in the .xml file.

Package all project data (Assembly .xml files, Representation files, LP Templates, Loadcase files, Job files and CSV templates) for transfer to others or for archival.

Create standard tuning sets that can be used in the Analysis Manager for automatically setting up quick modification runs in NVH analysis.

Use the Squeak and Rattle Director tool to create evaluation lines, evaluate them and optimize the interfaces to eliminate squeak and rattle issues.

The Crash application offers a tailored environment in HyperWorks that efficiently steers the Crash CAE specialist in CAE model building, starting from CAD geometry and finishing with a runnable solver deck in Radioss, LS-DYNA and PAM-CRASH 2G.

HyperWorks offers high quality tools for CFD applications enabling the engineer to perform modeling, optimization and post-processing tasks efficiently.

Essential utility tools developed using HyperWorks-Tcl.

Solver interfaces supported in Engineering Solutions.

A solver interface is made up of a template and a FE-input reader.

Support provided by the CAD readers and writers.

Browsers supply a great deal of view-related functionality by listing the parts of a model in a tabular and/or tree-based format, and providing controls inside the table that allow you to alter the display of model parts.

Panels contains pre-processing and post-processing tools.

Create, edit, and cleanup geometry.

Different types of mesh you can create in HyperWorks.

Create connections between parts of your model.

Create, organize and manage parts and subsystems.

Perform automatic checks on CAD models, and identify potential issues with geometry that may slow down the meshing process using the Verification and Comparison tools.

Overview of how to build a finite element model.

Morph the shape of your finite element model.

Setup an Optimization in Engineering Solutions.

Convert finite element models to another solver format.

Study relationships between data vectors in results files.

Learn how to use post-processing functions.

Noise, Vibration and Harshness (NVH) is an important vehicle attribute that directly affects the customer experience.

Create a complete vehicle assembly using external .csv files for assembly, tagpoints, connections, isolator, network diagram, symmetry and analysis.

Create a complete vehicle assembly using external .csv files for assembly, tagpoints, connections, isolator, network diagram, symmetry and analysis.

© 2023 Altair Engineering, Inc. All Rights Reserved.

Intellectual Property Rights Notice | Technical Support | Cookie Consent