Align 1D Elements

Use the Edit Beam: Align tool to reorder the N1 to N2 sequence of 1D element nodes.

This tool allows you to reorder element nodes using a vector or a system axis.

In this optional step, you can select elements in order to reorder N1 & N2 in ascending order along one or multiple axes if elements are aligned with such vector(s) in a given angle tolerance.

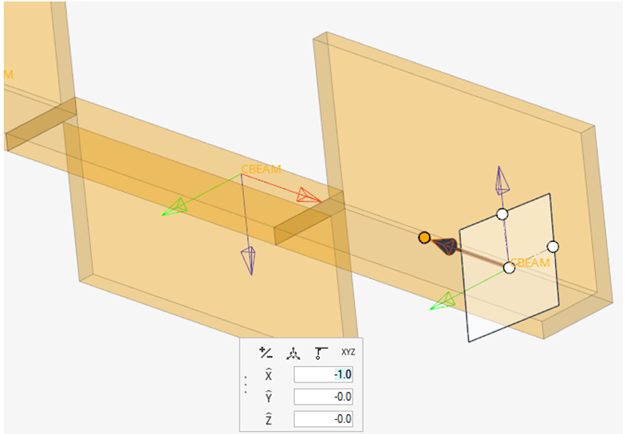

Figure 1.